Double-component crylic acid adhesive and preparation method thereof

An acrylic, two-component technology, used in adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of insufficient bonding strength, low activity, affecting curing speed, etc., to achieve good formability, high touch changing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

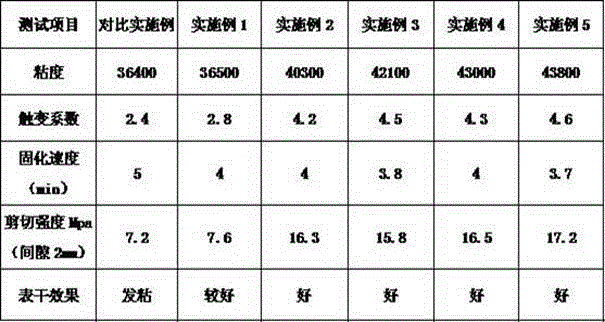

Examples

Embodiment 1

[0029] Example 1. Preparation of component A: 30g of methyl methacrylate, 10g of hydroxyethyl methacrylate, 10g of methacrylic acid, 8g of trimethylolpropane trimethacrylate, 15g of ABS resin, and 13g of neoprene After mixing, put it into the reaction kettle and stir for 3 hours at 20~30°C to dissolve completely and become a uniform liquid, then add 0.2g of hydroquinone, 1.5g of EDTA-Na, 3g of N,N dimethyl p-toluidine Stir for 1 hour, add 2 g of gas-phase silicon, 1.2 g of zinc dimethacrylate, stir for 30 minutes, and vacuumize for 1 hour to obtain component A;

[0030] Preparation of component B: put 30g of epoxy resin, 10g of cumene hydroperoxide, and 30g of dioctyl adipate into the reaction kettle in proportion and stir for 2 hours at 20~30°C to make it completely mixed evenly, and then add it into the gas phase 2 g of silicon and 0.2 g of naphthoquinone were stirred for 1 hour and vacuumized for 1 hour to obtain component B.

Embodiment 2

[0031] Example 2. Preparation of component A: Mix 15g of methyl methacrylate, 18g of tetrahydrofuran methacrylate, 10g of methacrylic acid, 8g of trimethylolpropane triacrylate, 15g of ABS resin, and 13g of hydroxyl-terminated liquid rubber , put into the reaction kettle and stir at 20~30°C for 3 hours to dissolve completely and become a uniform liquid, then add 0.2g of p-benzoquinone, 2g of EDTA-Na, 2g of N,N dihydroxyethyl-p-toluidine and stir for 1 hour, Add 1.2g of zinc dimethacrylate, add 3.4g of fumed silicon, stir for 30 minutes, and vacuumize for 1 hour to obtain component A;

[0032] Preparation of component B: Put 30g of bisphenol A epoxy resin, 30g of benzoyl peroxide, and 30g of dibutyl phthalate into the reaction kettle in proportion and stir for 4 hours at 20~30°C to make it completely mixed. Add 1.5 g of fumed silicon, 0.5 g of dye blue, and 0.2 g of naphthoquinone, stir for 1 hour, and vacuumize for 1 hour to obtain component B.

Embodiment 3

[0033] Example 3. Preparation of component A: 10 g of methyl methacrylate, 15 g of isobornyl acrylate, 10 g of methacrylic acid, 8 g of trimethylolpropane trimethacrylate, 15 g of SBS resin, and carboxyl-terminated nitrile butadiene liquid rubber After mixing 20g, put it into the reaction kettle and stir for 3 hours at 20~30°C to dissolve completely and become a uniform liquid, then add 0.1g of 2,6-di-tert-butyl-4-methylphenol and 1.5g of EDTA-Na in sequence , 3 g of triethylamine was stirred for 1 hour, 1.5 g of zinc methacrylate and 4 g of fumed silicon were added, stirred for 30 minutes, and vacuumized for 1 hour to obtain component A;

[0034] Preparation of component B: Put 30g of bisphenol F epoxy resin, 20g of benzoyl peroxide, 10g of cumene hydroperoxide, and 20g of dibutyl phthalate into the reaction kettle in proportion and stir at 20~30°C After 2 hours, make the mixture completely uniform, add 2 g of fumed silicon, 0.2 g of hydroquinone, stir for 1 hour, and vacuumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com