Acrylate structural glue suitable for zinc alloy bonding

A technology of acrylate and structural adhesives, which is applied in the direction of non-polymer organic compound adhesives, adhesives, adhesive additives, etc., and can solve problems affecting the reliability and stability of notebook machines, poor corrosion resistance, and reduced bonding strength. Problems, to achieve the effect of smooth glue, good adhesion, and even glue mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

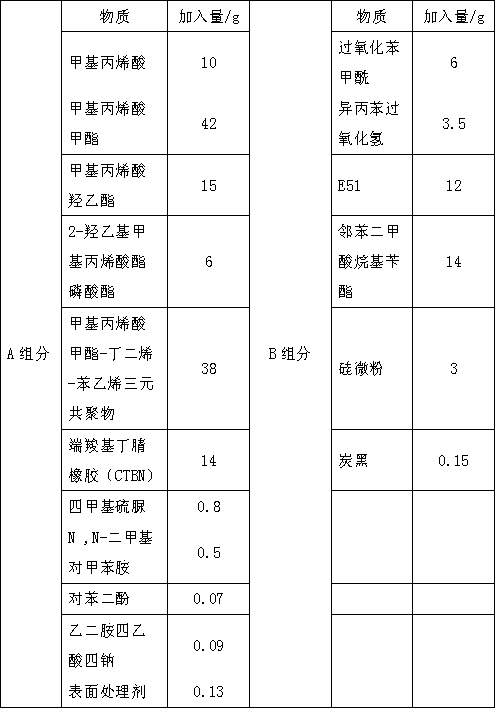

Embodiment 1

[0026]

[0027] Wherein, the surface treatment agent consists of:

[0028] Chromium phosphate: sodium sulfate: oxalic acid = 1.6: 0.8: 1

[0029] Concrete preparation steps are:

[0030] The preparation process of component A is to clean the reactor. First add 10g of methacrylic acid, 42g of methyl methacrylate, 15g of hydroxyethyl methacrylate, 6g of 2-hydroxyethyl methacrylate phosphate, methyl methacrylate-butadiene-styrene terpolymer 38g of carboxyl-terminated nitrile rubber (CTBN) 14g, stirred at high speed for 1.5h until the material was uniform and fine paste, then added 0.8g of tetramethylthiourea, 0.5g of N,N-dimethyl-p-toluidine, 0.07g of hydroquinone, 0.09g of tetrasodium edetate, and 0.13g of surface treatment agent, stirred at high speed for 1 hour, and finally evacuated for 5 minutes to defoam, and discharged to obtain component A of the finished product. In particular, during the entire stirring process, the temperature of the material in the reactor shoul...

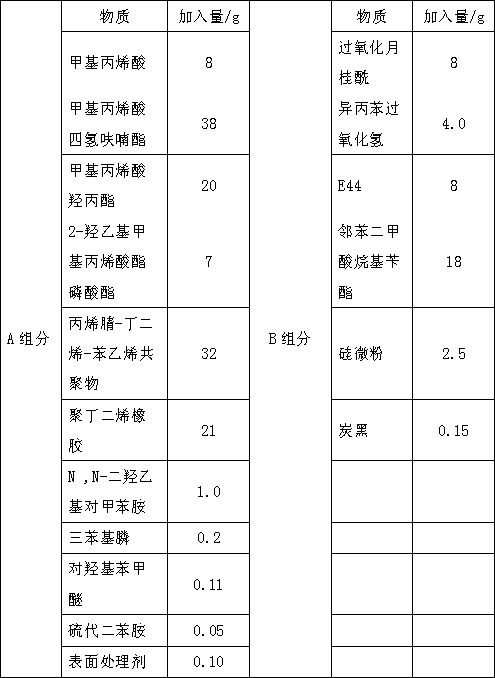

Embodiment 2

[0033]

[0034] Wherein, the surface treatment agent consists of:

[0035] Chromium Phosphate: Sodium Sulfate: Citric Acid = 1.8:0.7:1

[0036] Concrete preparation steps are:

[0037] The preparation process of component A is to clean the reactor. First add 8g of methacrylic acid, 38g of tetrahydrofuryl methacrylate, 20g of hydroxypropyl methacrylate, 7g of 2-hydroxyethyl methacrylate phosphate, 32g of acrylonitrile-butadiene-styrene copolymer, polybutylene Diene rubber 21g, stirred at high speed for 1.5h, until the material was uniform and fine paste, then added N,N-dihydroxyethyl-p-toluidine 1g, triphenylphosphine 0.2g, p-hydroxyanisole 0.11g, sulfur Substituted diphenylamine 0.05g, surface treatment agent 0.10g, stirred at high speed for 1 hour, and finally evacuated for 5 minutes for defoaming, and discharged to obtain component A of the finished product. In particular, during the entire stirring process, the temperature of the material in the reactor should be cont...

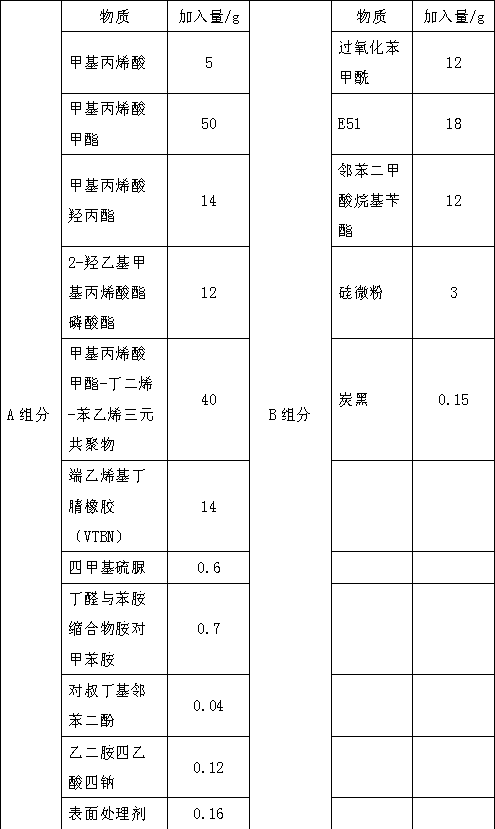

Embodiment 3

[0040]

[0041] Wherein, the surface treatment agent consists of:

[0042] Chromium nitrate: sodium sulfate: oxalic acid = 2.0: 1.0: 1

[0043] Concrete preparation steps are:

[0044] The preparation process of component A is to clean the reactor. First add 5g of methacrylic acid, 50g of methyl methacrylate, 14g of hydroxypropyl methacrylate, 12g of 2-hydroxyethyl methacrylate phosphate, methyl methacrylate-butadiene-styrene terpolymer 40g of compound, 14g of vinyl-terminated nitrile rubber (VTBN), stirred at high speed for 1.5h, until the material was uniform and fine paste, then added 0.6g of tetramethylthiourea, 0.7g of butyraldehyde and aniline condensate amine, p-tert 0.04g of butyl catechol, 0.12g of tetrasodium ethylenediaminetetraacetic acid, and 0.16g of surface treatment agent, stirred at high speed for 1 hour, and finally evacuated for 5 minutes to defoam, and discharged to obtain component A of the finished product. In particular, during the entire stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com