Composite colloidal material based on inorganic nanowires and its preparation method and 3D printing application

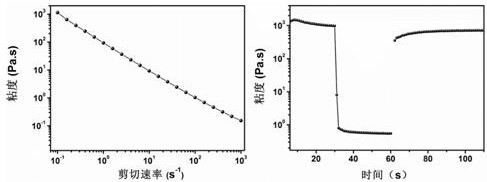

A colloidal material, inorganic nanotechnology, applied in applications, nanotechnology, additive processing, etc., can solve problems such as reducing the printability and functionality of functional inks, limiting the types of micro-nano functional materials, and reducing the mechanical stability of target devices. Achieve the effect of expanding application fields and excellent rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Weigh 0.16g prepared by chemical method (D. A. Dikin, S. Stankovich, E. J. Zimney, R.D. Piner, G. H. B. Dommett, G. Evmenenko, S. T. Nguyen, R. S. Ruoff, Nature 2007, 448 , 457) sheets of graphene oxide with a size of about 1-2 μm were placed in a beaker, 80ml of deionized water was added, and 2mg / ml graphene oxide dispersion was obtained by ultrasonication for 30 minutes, and 1mol / L NaHCO 3 The solution adjusts the pH value of the graphene oxide dispersion to 6.5.

[0043] (2) Weigh 6ml of silver nanowire (length 5μm, diameter 30-40nm) dispersion (10 mg / ml) into the reagent bottle, add 10ml of graphene oxide dispersion obtained in step (1), and ultrasonically vibrate to make it Disperse again. Suction filtration with a microporous membrane, washing with deionized water several times, and sucking off the supernatant to obtain a composite colloid of silver nanowires and graphene oxide.

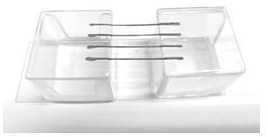

[0044] (3) Scrape off the conductive composite colloid obtained in step (2),...

Embodiment 2

[0047] (1) Weigh 0.16g of graphene oxide with a sheet size of about 1-2μm prepared by a chemical method and place it in a beaker, add 80ml of deionized water, and ultrasonicate for 30 minutes to obtain a 2mg / ml graphene oxide dispersion. L NaHCO 3 The solution adjusts the pH value of the graphene oxide dispersion to 6.5.

[0048] (2) Weigh 6ml of the silver nanowire (length 5μm, diameter 30-40nm) dispersion (10 mg / ml) into the reagent bottle, add 10ml of the graphene oxide dispersion obtained in step (1), and ultrasonically vibrate to make it Disperse again. Suction filtration with a microporous membrane, washing with deionized water for several times, sucking off the supernatant, and shaking to obtain a uniform silver nanowire-graphite oxide composite colloid with rheological properties.

Embodiment 3

[0050] (1) Weigh 0.16g of graphene oxide with a sheet size of about 1-2μm prepared by a chemical method and place it in a beaker, add 80ml of deionized water, and ultrasonicate for 30 minutes to obtain a 2mg / ml graphene oxide dispersion. L NaHCO 3 The solution adjusts the pH value of the graphene oxide dispersion to 6.5.

[0051] (2) Weigh 3ml silver nanowire (length 5μm, diameter 30-40nm) dispersion (10mg / ml) into the reagent bottle, add 10mg MnO 2 (10 μm in length, 10 nm in diameter) and 10 ml of the graphene oxide dispersion liquid obtained in step (1), ultrasonically and vibrated to make it redispersed. Suction filter with a microporous membrane, wash with deionized water several times, and suck off the supernatant to obtain a silver nanowire-manganese dioxide-graphene oxide ternary electrochemical composite colloid.

[0052] (3) Scrape off the composite colloid obtained in step (2), add 5μl 5% Zonyl® FS-30 surfactant, add water to quantify to 500mg, and oscillate to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com