Novel UV scrubbing-free stain-resistant sealing layer for nails and preparation method of novel UV scrubbing-free stain-resistant sealing layer

A scrub-free, new type of technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of easy putty and pollution on the sealing layer, and achieve the effect of good wear resistance, good stability and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

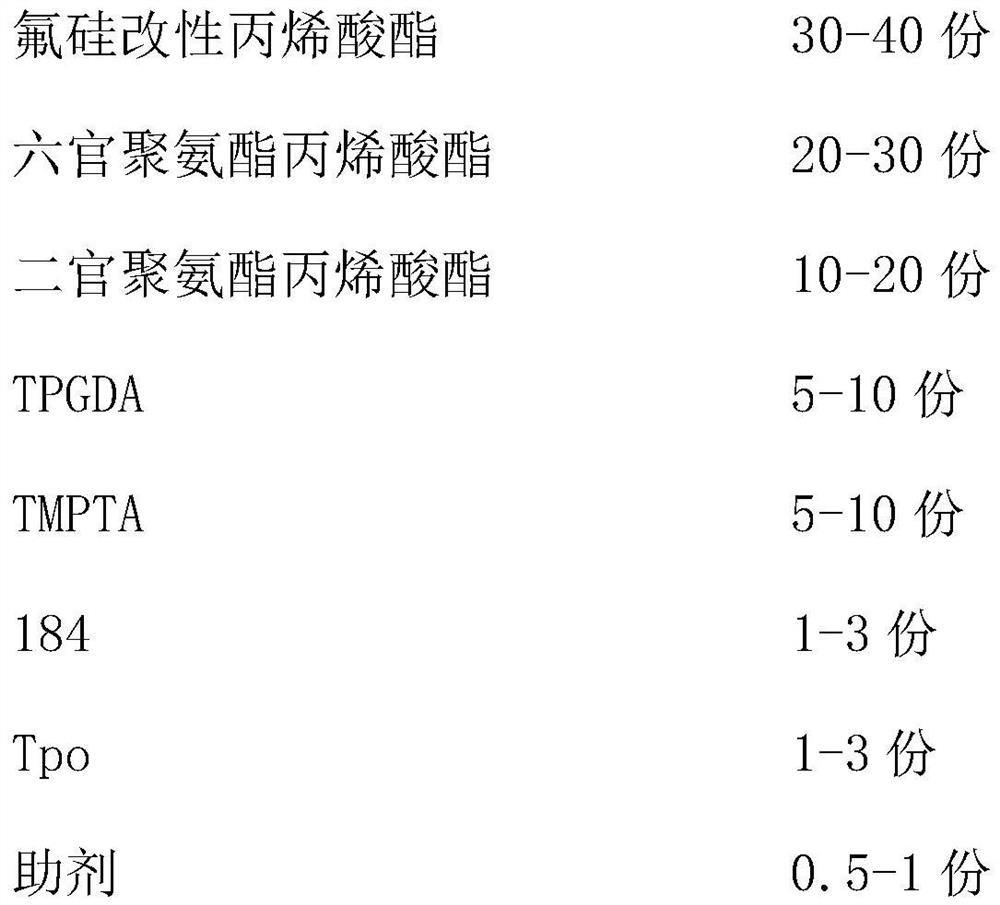

[0017] A novel UV scrub-free and stain-resistant sealing layer for nails, comprising the following components in parts by weight:

[0018]

[0019] A preparation method for a novel UV scrub-free and stain-resistant sealant for nails, comprising the following steps:

[0020] 1) Mix fluorosilicon-modified acrylate, hexafunctional urethane acrylate, difunctional urethane acrylate, TPGDA, TMPTA, 184, Tpo and additives and stir in the dark at high speed;

[0021] 2) Perform filtration and defoaming to obtain a novel UV scrub-free and stain-resistant sealing material for nails.

[0022] In the step 1), the stirring rate is 1500 rpm, and the temperature is 70 degrees Celsius.

Embodiment 2

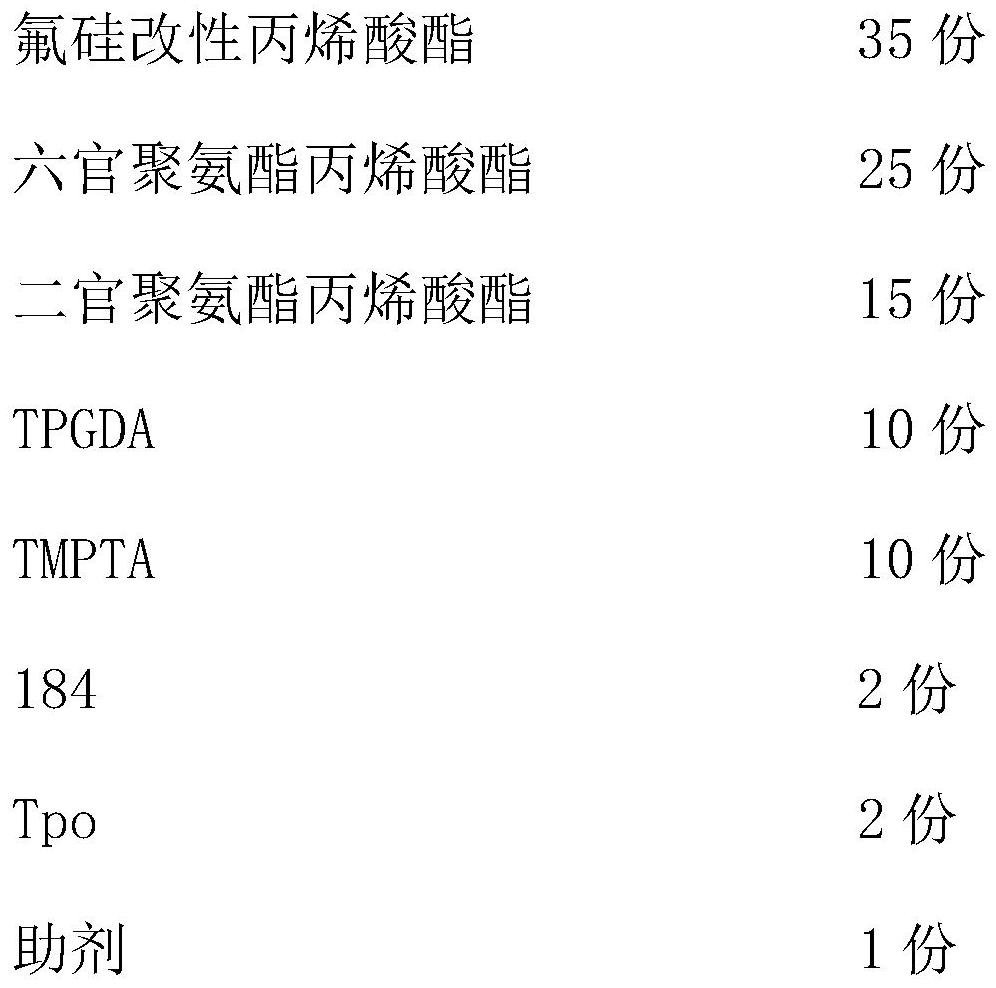

[0024] A novel UV scrub-free and stain-resistant sealing layer for nails, comprising the following components in parts by weight:

[0025]

[0026] A preparation method for a novel UV scrub-free and stain-resistant sealant for nails, comprising the following steps:

[0027] 1) Mix fluorosilicon-modified acrylate, hexafunctional urethane acrylate, difunctional urethane acrylate, TPGDA, TMPTA, 184, Tpo and additives and stir in the dark at high speed;

[0028] 2) Perform filtration and defoaming to obtain a novel UV scrub-free and stain-resistant sealing material for nails.

[0029] In the step 1), the stirring rate is 1500 rpm, and the temperature is 75 degrees Celsius.

Embodiment 3

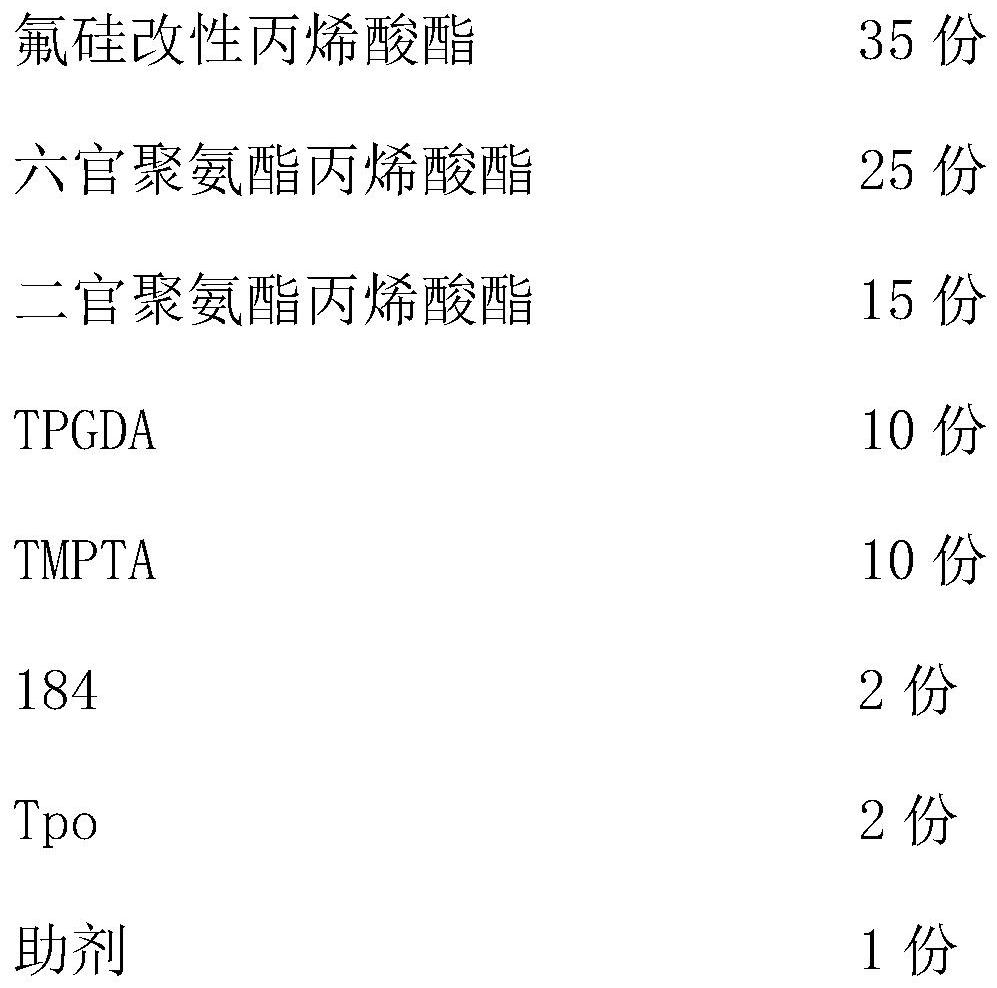

[0031] A novel UV scrub-free and stain-resistant sealing layer for nails, comprising the following components in parts by weight:

[0032]

[0033] A preparation method for a novel UV scrub-free and stain-resistant sealant for nails, comprising the following steps:

[0034] 1) Mix fluorosilicon-modified acrylate, hexafunctional urethane acrylate, difunctional urethane acrylate, TPGDA, TMPTA, 184, Tpo and additives and stir in the dark at high speed;

[0035] 2) Perform filtration and defoaming to obtain a novel UV scrub-free and stain-resistant sealing material for nails.

[0036] In the step 1), the stirring rate is 1500rpm), and the temperature is 70 degrees Celsius.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com