Robot system and method for masonry of fabricated building main body

A robot system and building main body technology, which is applied to machine tools suitable for grinding workpiece planes, machine tools suitable for grinding workpiece edges, and processing of building materials, etc. Intensive production and assembly, assembly buildings, and prefabricated building system chains have not been fully established, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

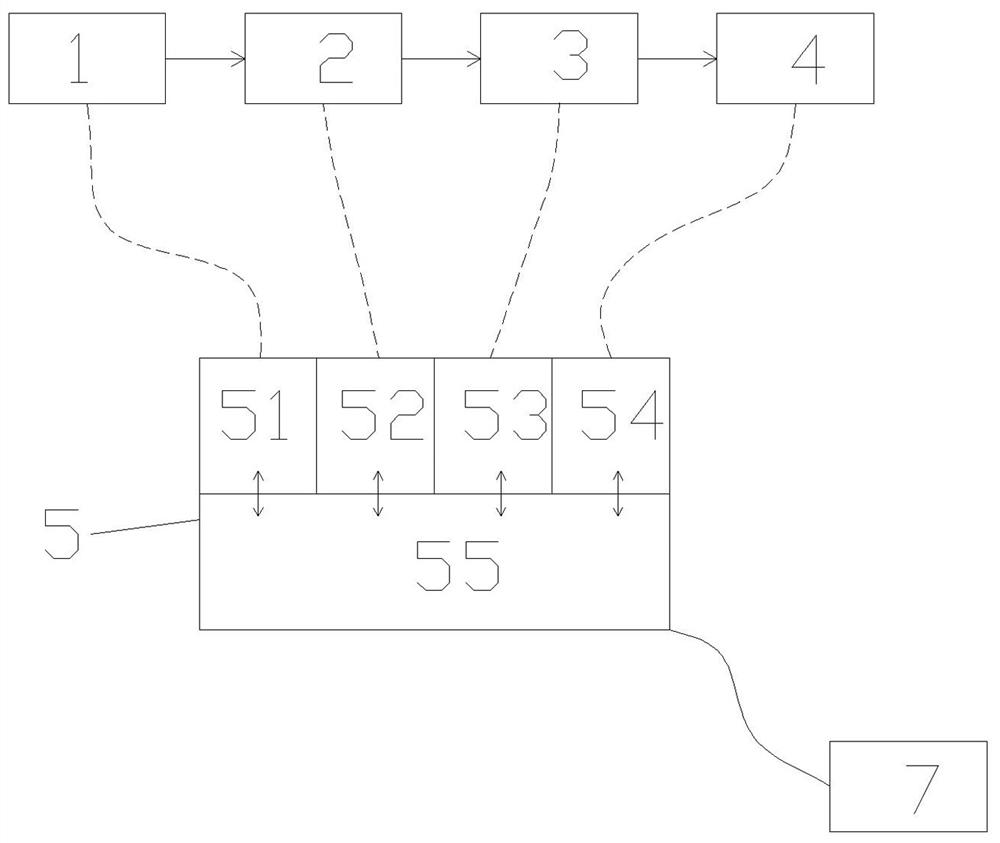

[0030] Such as figure 1 As shown, a robot system for masonry of a prefabricated building body includes a grinding device 1, a cutting device 2, a transportation device 3, a robot device 4, and a control system 5;

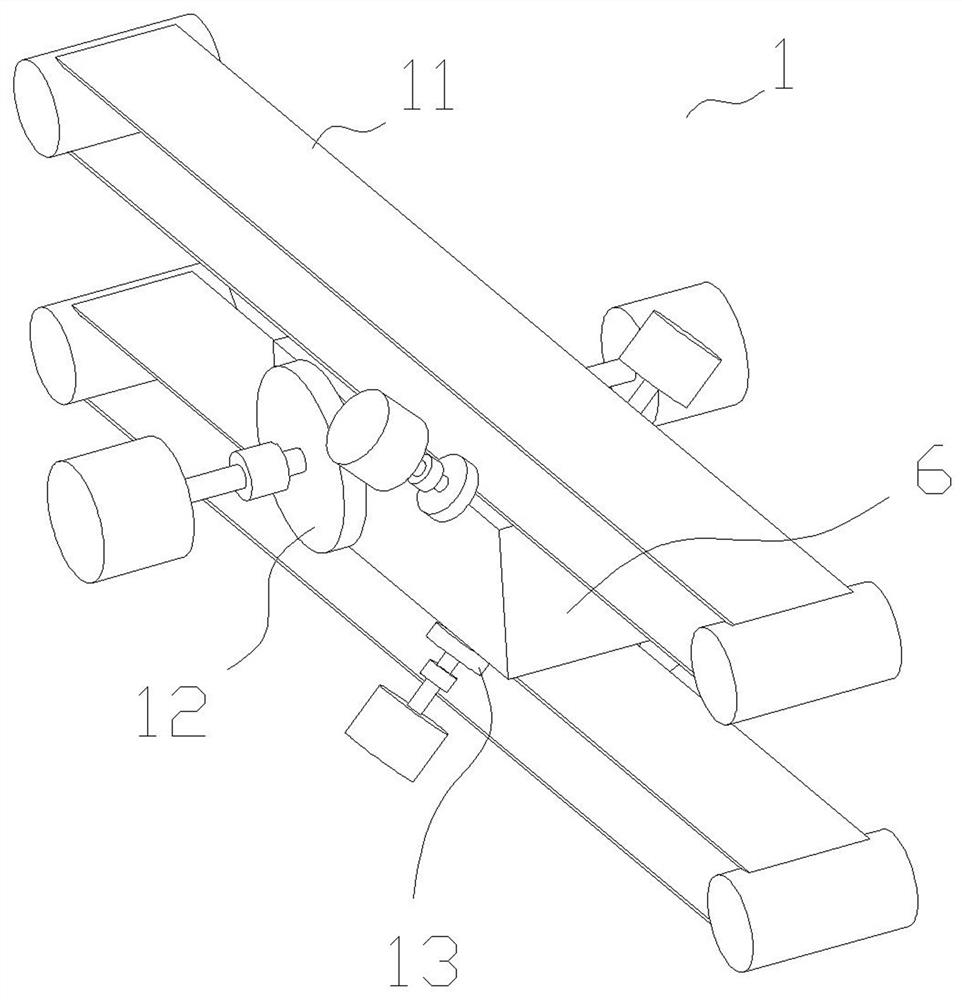

[0031] Such as figure 2 As shown, the grinding device 1 includes a block moving device 11, a surface grinding assembly 12 and a corner grinding assembly 13 for grinding the moving block 6;

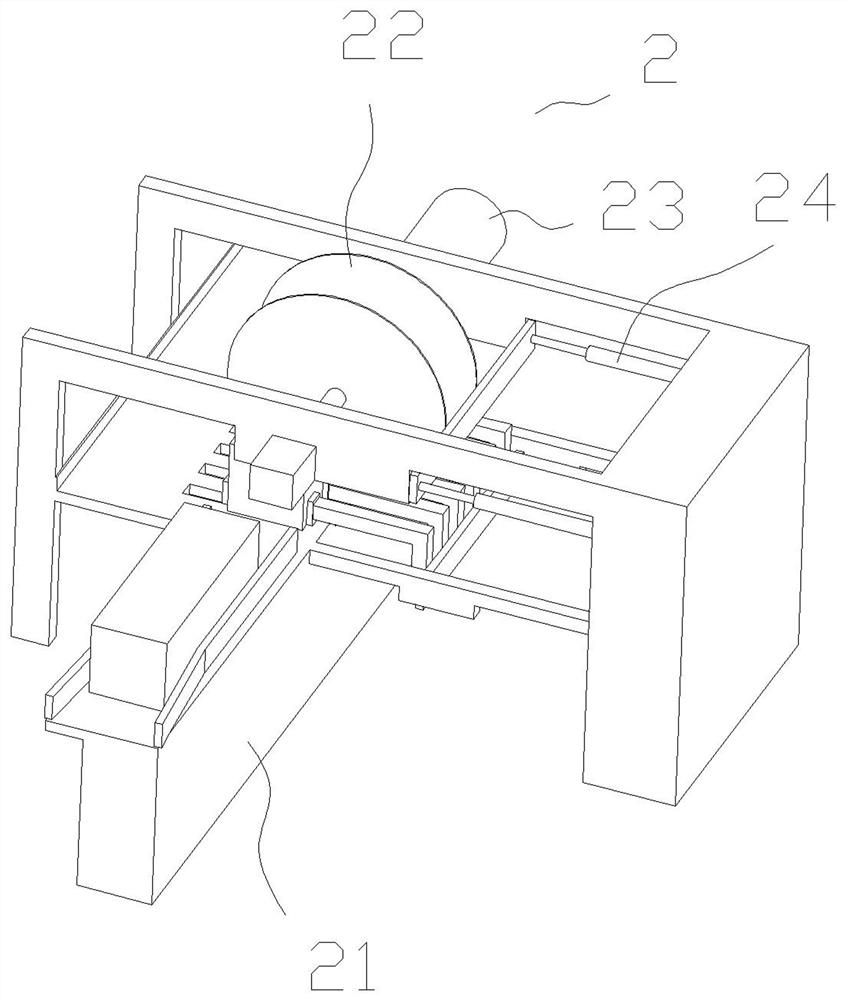

[0032] Such as image 3 As shown, the cutting device 2 includes a cutting table 21, and two coaxial cutting pieces 22 are arranged on the top of the cutting table 21, and the cutting pieces 22 are arranged on a rotating shaft driven by a cutting motor 23. The device 24 is driven to move horizontally above the cutting table 21; only two cutting slices are drawn in the figure, which obviously cuts the block into three pieces. According to actual needs, the block can be differently cut by changing the number and position of the cutting slices. Segmented cutting process.

[003...

Embodiment 2

[0040] The method of using the aforementioned robot system to build the main body of the prefabricated building includes the following steps:

[0041] Use the grinding device to grind the blocks;

[0042] Use the cutting device to cut the polished blocks as needed;

[0043] Stamp the cut blocks on the transport device;

[0044] Put the mortar into the mortar box and the lock bolt into the lock box, the lock box moves to the top of the mechanical arm through the lock box conveyor chain, the spray nozzle sprays the blocks on the transport vehicle, and the block gripper Pick up the block, rotate the mechanical arm to build the block to the desired position, and insert the bolt in the lock box into the bolt hole of the block by the nail bolt device, press at least one bolt each time, and build a block. After the blocks are arranged, the upper surface of the built blocks is sprayed, and then the next row of blocks is built.

[0045] The aforementioned embodiments are applicable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com