Polarizing film with adhesive layer, and image display device

A technology of adhesive layer and polarizing film, which is applied in the direction of adhesive type, ester copolymer adhesive, film/sheet adhesive, etc., to suppress the deterioration of optical reliability, good optical reliability, Excellent antistatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0157]

[0158] The resin composition for transparent layers can be prepared by any appropriate method. For example, it can be prepared by mixing a polymer (a), an epoxy resin (b), and any appropriate additives used as necessary in any appropriate solvent. Moreover, when polymerizing a polymer (a) by solution polymerization, it can prepare by adding and mixing an epoxy resin (b) and arbitrary appropriate additives to the polymerization solution of a polymer (a).

[0159] As a forming material other than the above-mentioned forming material containing the urethane prepolymer (a), the above-mentioned forming material containing the epoxy resin, and the above-mentioned forming material containing the composition containing the polymer (a) and the epoxy resin (b) The material of the layer includes, for example, a cyanoacrylate-based material, an epoxy-based material, a urethane acrylate-based material, and the like.

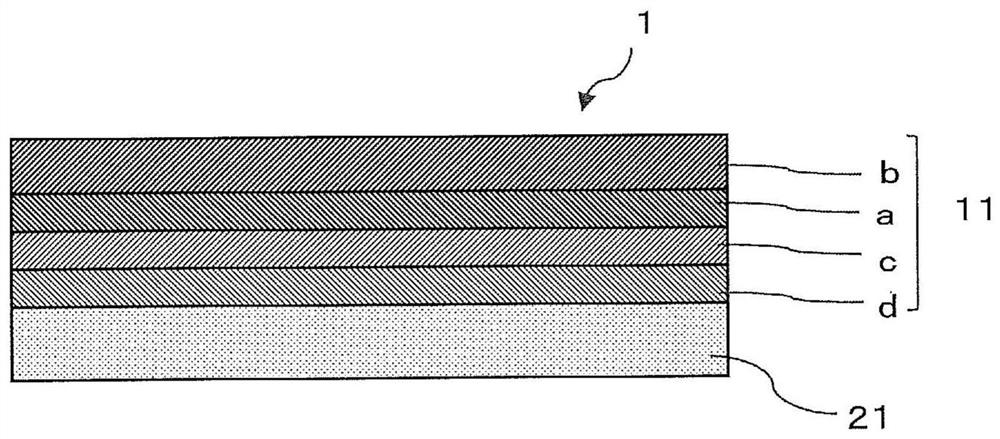

[0160] Formation of the above-mentioned transparent layer ca...

Embodiment 1

[0297]

[0298] A monomer mixture containing 99 parts of butyl acrylate and 1 part of 4-hydroxybutyl acrylate was charged into a 4-necked flask equipped with a stirring blade, a thermometer, a nitrogen gas introduction tube, and a condenser. Further, 0.1 part of 2,2'-azobisisobutyronitrile was added as a polymerization initiator with 100 parts of ethyl acetate to 100 parts of the above-mentioned monomer mixture (solid content), and nitrogen gas was introduced while stirring slowly to carry out nitrogen replacement. Thereafter, the liquid temperature in the flask was kept at around 55° C., and the polymerization reaction was performed for 8 hours to prepare a solution of a (meth)acrylic polymer having a weight average molecular weight (Mw) of 1.6 million and Mw / Mn=3.7.

[0299] (Preparation of Adhesive Composition)

[0300] With respect to 100 parts of solid content of the solution of the acrylic polymer obtained above, 0.1 part of an isocyanate crosslinking agent (Takenate D...

Embodiment 2~9、 comparative example 1~3

[0309] Embodiment 2~9, comparative example 1~3, reference example

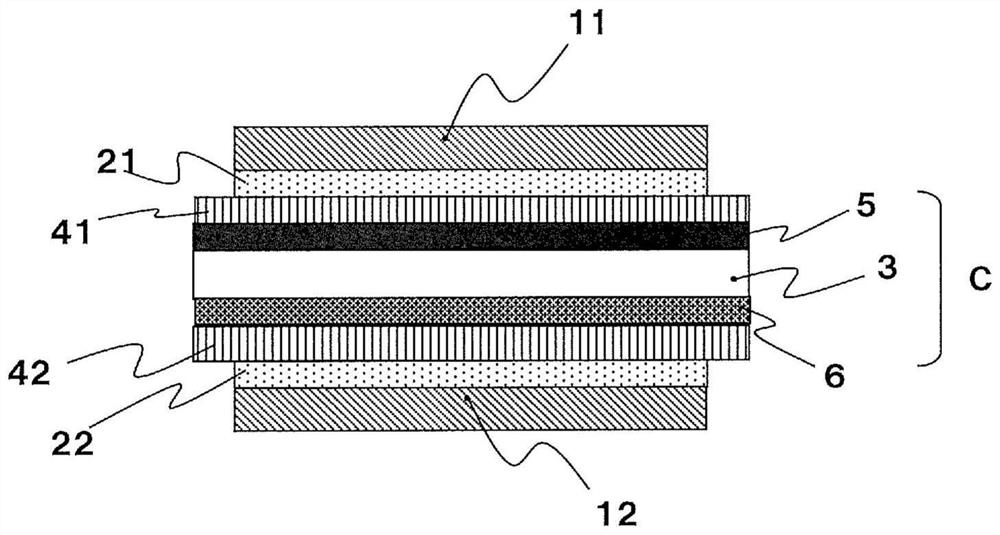

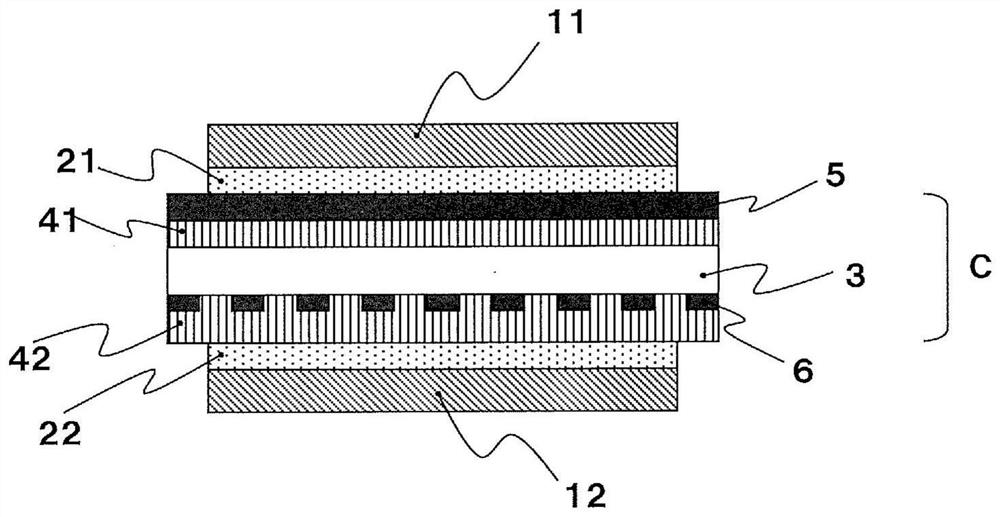

[0310] In Example 1, as shown in Table 1, the type of the polarizing film, the composition of the monomer mixture used in the preparation of the acrylic polymer (A), and the ionic compound used in the preparation of the adhesive composition ( B) The type (EMI-FSI or Li-TFSI) or its compounding ratio, the thickness of the adhesive layer, the presence or absence of a conductive layer, the presence or absence of a transparent layer forming material, the type or its thickness are shown in Table 1 Except having changed, it carried out similarly to Example 1, and produced the one side protection (or both sides protection) polarizing film with an adhesive layer.

[0311] In addition, for the transparent layer of Example 9, the above-mentioned transparent layer-forming material C was applied to one side of the polarizer of the above-mentioned one-side protective polarizing film (the one without the transparent protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com