Leisure preserved fish processing method

A processing method and technology of bream, applied in the direction of lactobacillus, bacteria used in food preparation, food science, etc., can solve the problems of high salt content, unstable flora, long pickling and fermentation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

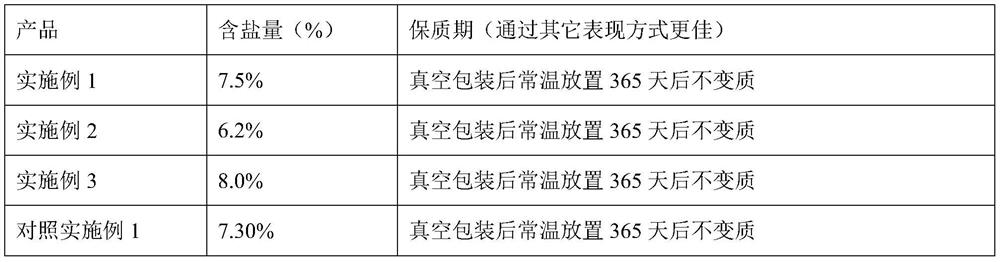

Embodiment 1

[0032] The leisure bream processing method described in the present embodiment may further comprise the steps:

[0033] S1 Raw material pretreatment: Freshwater fish (grass carp or silver carp) is descaled, finned, headed, tailed, viscerally removed, and blood on the surface is cleaned; then cut into 1.5±0.5cm wide fish pieces.

[0034] S2 marinating: Put the fish pieces into a vacuum tank, mix the fish pieces with the auxiliary materials containing red yeast rice powder, the auxiliary materials are composed of salt, sucrose, white wine and red yeast rice powder, 100 parts of fish blocks correspond to 7 parts of table salt and 2 parts of sucrose , 6 parts of 50° white wine, 0.8 part of red yeast rice flour; then carry out vacuum negative pressure pickling, during the pickling process, the temperature in the vacuum tank is 6°C, the vacuum degree is 0.08Mpa, and pickling for 7h.

[0035] S3 fermentation: prepare sterilized soy clear liquid, the preparation method of sterilized s...

Embodiment 2

[0044] The leisure bream processing method described in the present embodiment may further comprise the steps:

[0045] S1 Raw material pretreatment: Freshwater fish (grass carp or silver carp) is descaled, finned, headed, tailed, viscerally removed, and blood on the surface is cleaned; then cut into 1.5±0.5cm wide fish pieces.

[0046] S2 marinating: put the fish pieces into a vacuum tank, mix the fish pieces with the auxiliary materials containing red yeast rice powder, the auxiliary materials are composed of salt, sucrose, white wine and red yeast rice powder, 100 parts of fish blocks correspond to 6 parts of table salt and 1.5 parts of sucrose , 5 parts of 50° white wine, 0.5 part of red yeast rice flour; then carry out vacuum negative pressure pickling, during the pickling process, the temperature in the vacuum tank is 6°C, the vacuum degree is 0.08Mpa, and pickling for 6h

[0047] S3 fermentation: prepare sterilized soy clear liquid, the preparation method of sterilized ...

Embodiment 3

[0056] The leisure bream processing method described in the present embodiment may further comprise the steps:

[0057] S1 Raw material pretreatment: Freshwater fish (grass carp or silver carp) is descaled, finned, headed, tailed, viscerally removed, and blood on the surface is cleaned; then cut into 1.5±0.5cm wide fish pieces.

[0058] S2 marinating: put the fish pieces into a vacuum tank, mix the fish pieces with the auxiliary materials containing red yeast rice powder, the auxiliary materials are composed of salt, sucrose, white wine and red yeast rice powder, 100 parts of fish blocks correspond to 8 parts of table salt and 3 parts of sucrose , 8 parts of 50° white wine, 1.0 part of red yeast rice flour; then carry out vacuum negative pressure pickling, during the pickling process, the temperature in the vacuum tank is 2-8°C, the vacuum degree is 0.08Mpa, and pickle for 6-8h.

[0059] S3 fermentation: prepare sterilized soy clear liquid, the preparation method of sterilized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com