Reaction device and system and method for synthesizing acetic acid from carbonyl

A reaction device, acetic acid technology, applied in the chemical industry, can solve problems such as difficult stable and safe operation, easy damage to shaft seals and bearings, uneven liquid distribution, etc., to eliminate hidden dangers of parking, reduce temperature difference, and uniform temperature field Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

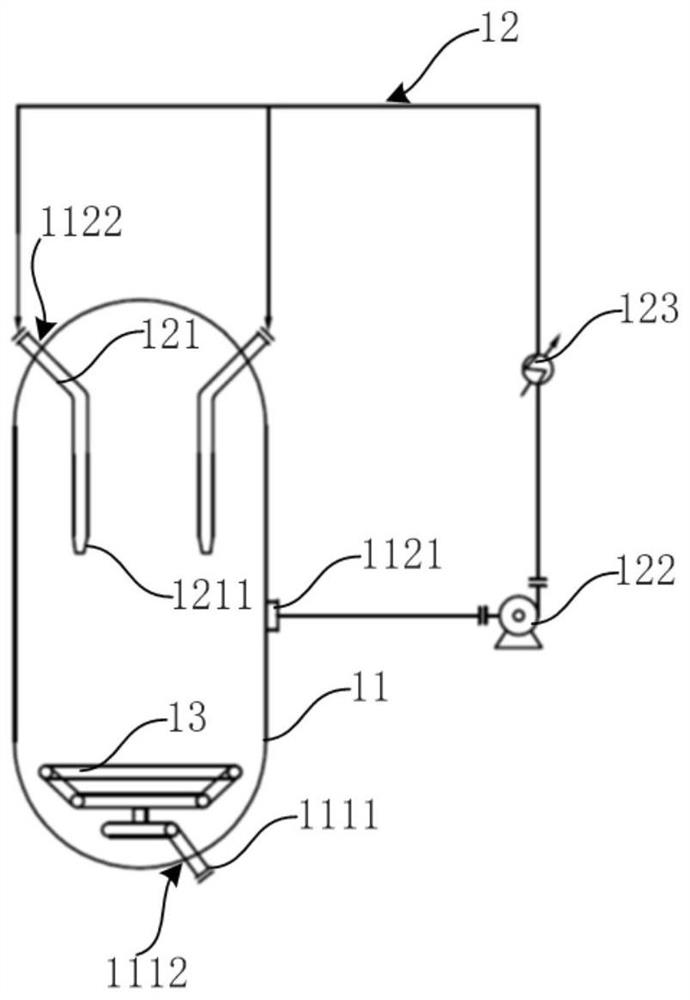

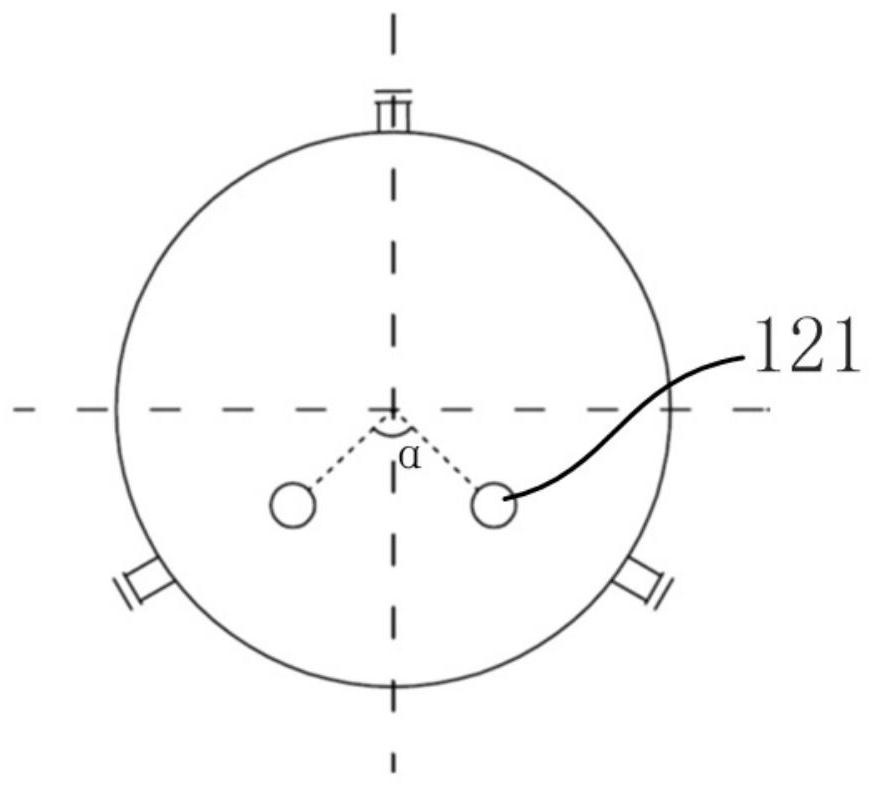

[0097] Methanol low-pressure synthetic acetic acid reaction device, the height of the cylinder of the reactor (i.e. the length of the straight side of the cylinder of the reactor) is 5m, and the diameter is 3m. After the transformation of the reactor, the figure 1 , image 3 and Figure 4 As shown in the circulating fluid stirring part and the three-dimensional multi-ring raw material gas distribution stirring part, the included angle of the vertical projection of the central axis of the two circulating fluid feeds on the radial plane of the reactor is 150°, and the two circulating fluid feeding The nozzle at the end of the material pipe is located at 5 / 6m below the liquid surface (1 / 6 of the length of the straight side of the reactor), the fluid flow rate of the nozzle of the circulating fluid feeding pipe is 5m / s, and the circulating fluid feed The total flow of fluid at the outlet of the pipe is 200m 3 / h, 5 times the volume of the reaction solution. The raw material gas...

Embodiment 2

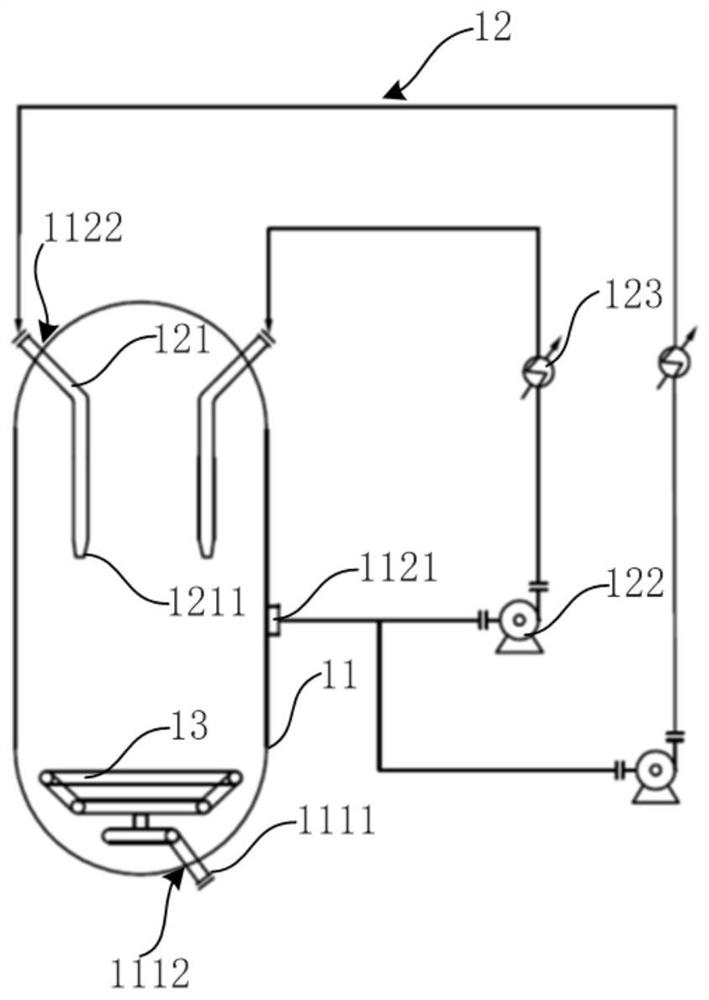

[0099] Methanol low-pressure synthetic acetic acid reaction device, the height of the reactor cylinder is 5m, the diameter is 3m, after the transformation of the reactor, adopt figure 2 , image 3 and Figure 4 The circulating fluid stirring part shown and the three-dimensional multi-ring raw material gas distribution stirring part, three circulating fluid feeding pipes, and the folder of the vertical projection of the central axis of the adjacent circulating fluid feeding pipe 121 on the radial plane of the reactor The angle is 120°, the nozzle at the end of the circulating fluid feeding pipe is located at 10 / 6m below the liquid surface (2 / 6 of the length of the straight side of the reactor), and the flow rate of the fluid ejected from the nozzle of the circulating fluid feeding pipe is 11m / s, the total fluid flow at the outlet of the circulating fluid feed pipe is 260m 3 / h is 6.2 times the volume of the reaction solution. The raw material gas distribution stirring unit ...

Embodiment 3

[0101] Methanol low-pressure synthesis of acetic acid reaction device, the height of the reactor cylinder is 5m, the diameter is 3m, after the transformation of the reactor, adopt figure 2 , image 3 and Figure 4 The shown circulating fluid stirring part and the three-dimensional multi-ring material gas distribution stirring part, four circulating fluid feed pipes, and the folder of the vertical projection of the central axis of the adjacent circulating fluid feed pipe 121 on the radial plane of the reactor The angle is 60°, the nozzle at the end of the circulating fluid feeding pipe is located at 15 / 6m below the liquid surface (1 / 2 of the length of the straight side of the reactor), and the flow rate of the fluid ejected from the nozzle of the circulating fluid feeding pipe is 15m / s, the total fluid flow at the outlet of the circulating fluid feed pipe is 320m 3 / h is 7.5 times the volume of the reaction solution. The raw material gas distribution and stirring components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com