Boron coating method with high efficiency and high boron utilization rate

A high-efficiency, high-utilization technology, applied to coatings, devices for coating liquids on surfaces, and pre-treated surfaces, can solve problems such as the inability to guarantee film thickness and uniformity, and the uncontrollable thickness of boron films, and achieve control Thickness, the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

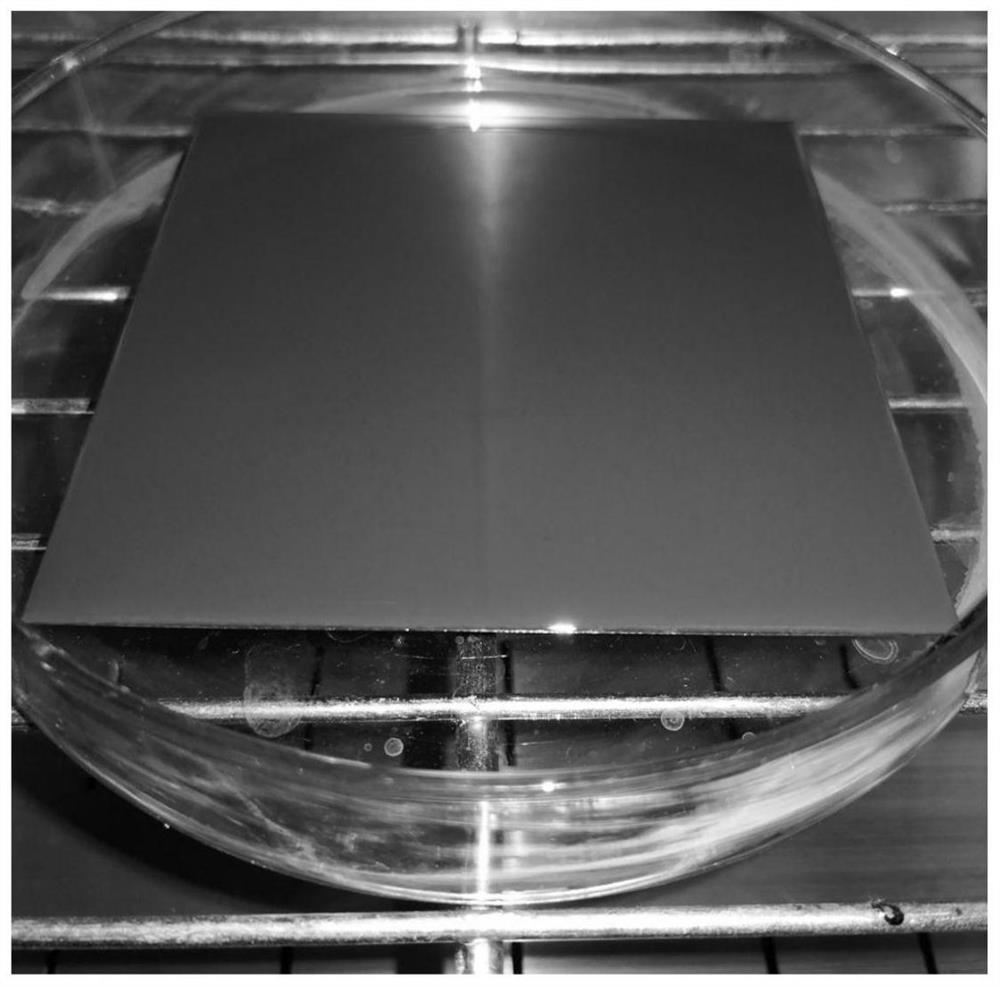

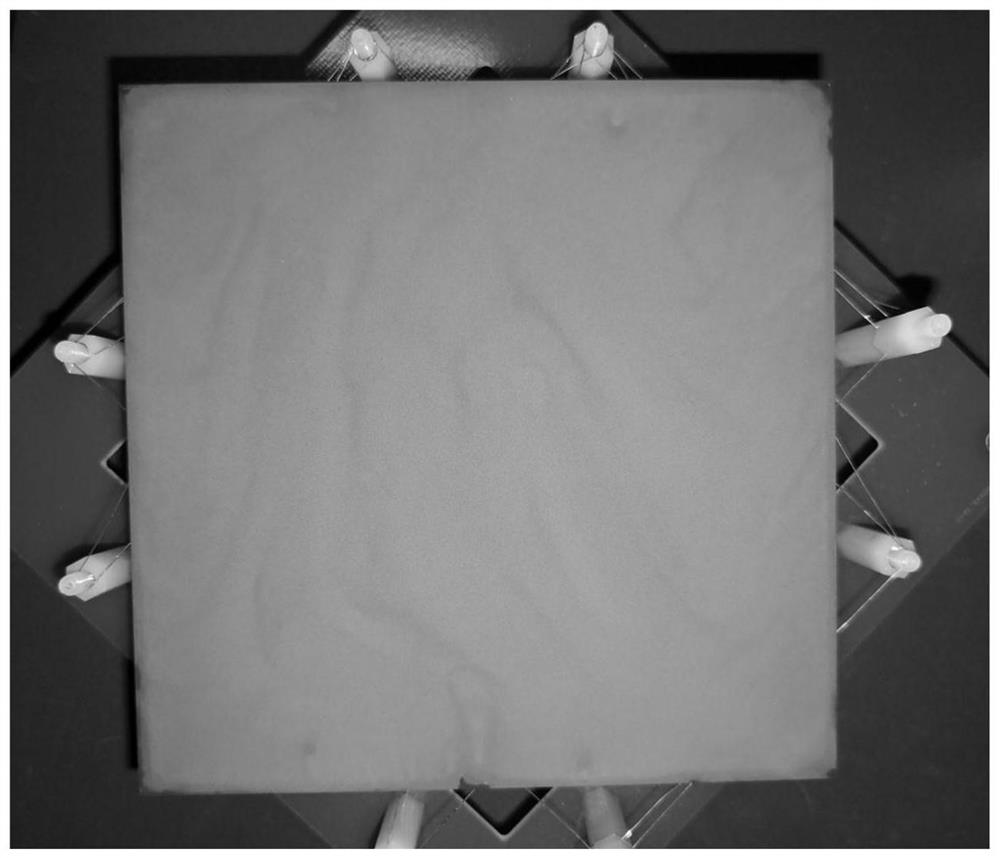

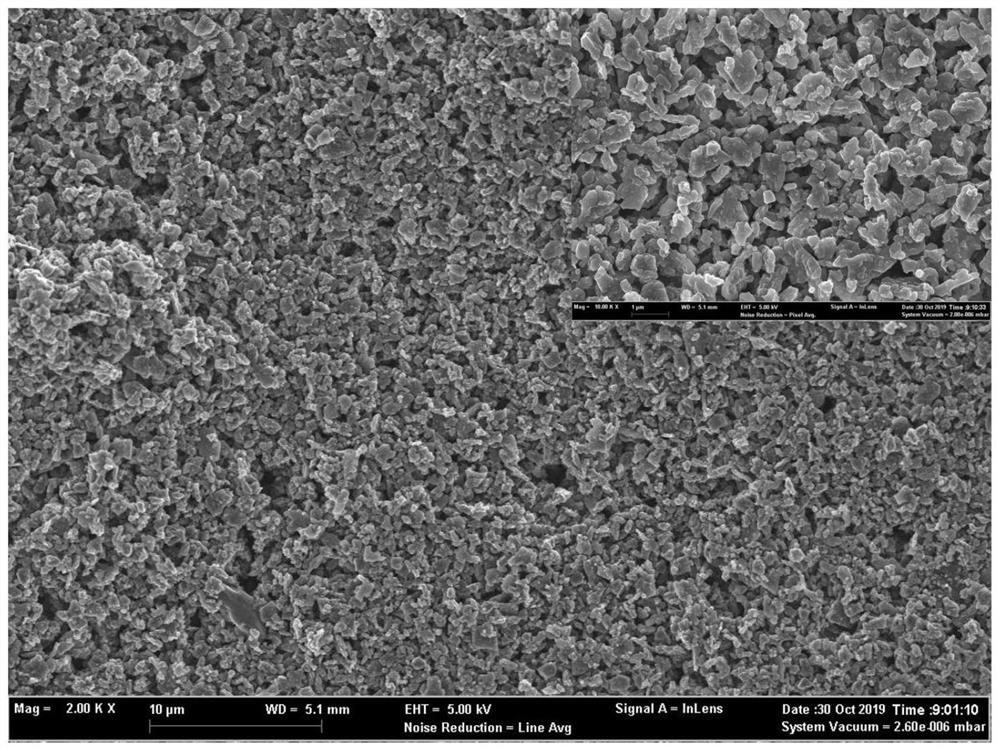

[0023] A boron-coating method with high efficiency and high boron utilization rate. The method specifically includes two steps of preparing a boron-coating liquid and boron-coating. First, when preparing the boron-coating liquid, select two 100ml and one 25ml beakers, respectively Numbering, then select two glass rods, number them separately, wash off industrial oil with alcohol, wash with deionized water, and dry for later use. The size and number of beakers can be adjusted according to specific needs.

[0024] Add 0.16g epoxy resin to No. 1 100ml beaker, then add 30g alcohol, and use No. 1 glass rod to stir fully to make the resin completely dissolve in alcohol; then add 1g nano boron powder to No. 2 100ml beaker, add 10g alcohol, Use No. 2 glass rod to fully stir to make it fully mixed with alcohol. The fat-to-boron ratio selected in this example is 0.16.

[0025] Add 0.0392g of curing agent to No. 1 100ml beaker, use No. 1 glass rod to fully stir and mix it evenly, then po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com