Process for extracting ammonium thiosulfate and ammonium thiocyanate from coke-oven gas desulfurization waste liquid

A technology of ammonium thiosulfate and desulfurization waste liquid is applied in the process of ammonium thiocyanate and the field of extraction of ammonium thiosulfate, which can solve the problems of increased cost, low salt purity, time-consuming and labor-intensive, etc., so as to avoid cost waste and extract The effect of high rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

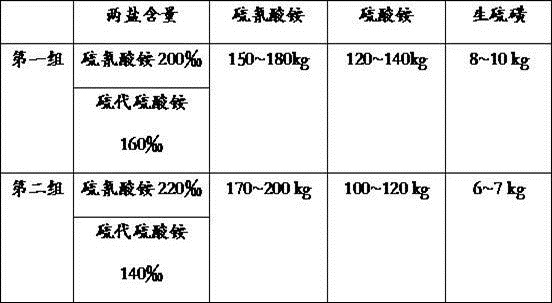

Image

Examples

Embodiment

[0018]A. The filtered desulfurization waste liquid is supplied into the transmezzanu, and activated carbon is added to the decolorized kettle, stirred, heated to 100 to 110 ° C, resulting in purified desulfurization fluid;

[0019]B. The desulfurization liquid obtained by step A is separated by the filtrate to separate the activated carbon and the decolor, and the decolorization is pumped by the decolorized liquid to the evaporation kettle;

[0020]C. The decolorization is heated to 60 to 80 ° C under the evaporation kettle, which is heated to 60 to 80 ° C, and the concentration of 54 ~ 58% concentrate is obtained, and the concentrated fluid is supplied to a thiosidin;

[0021]D. Under the conditions of the kettle of the thioclastin, concentrated fluid fluid filtration in the thiocyclic centrifuge in the concentrated crystal crystal kettle to obtain corresponding first sulfur substand and first sulfur generation. Centrifugal liquid;

[0022]E. The first sulfur substation solid obtained by step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com