Industrial wastewater anaerobic ammonia oxidation deep denitrification device and method thereof

A technology for anaerobic ammonium oxidation and industrial wastewater, applied in the field of deep denitrification of industrial wastewater anaerobic ammonium oxidation, can solve the problems of reducing technical advantages, increasing process complexity, increasing investment and operating costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A coal-based ethylene glycol wastewater, the water volume is 4000m 3 / d, the concentration of ammonia nitrogen is 500-1000mg / L, and the concentration of COD is 500-1500mg / L, which is a typical low C / N process wastewater.

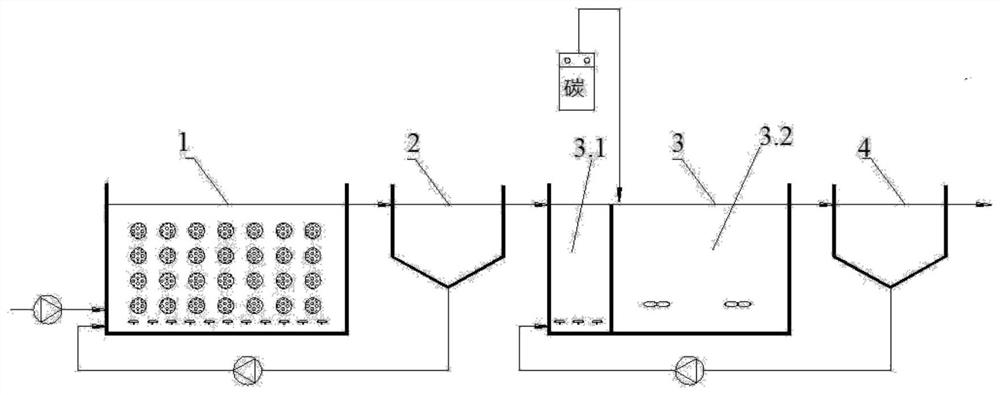

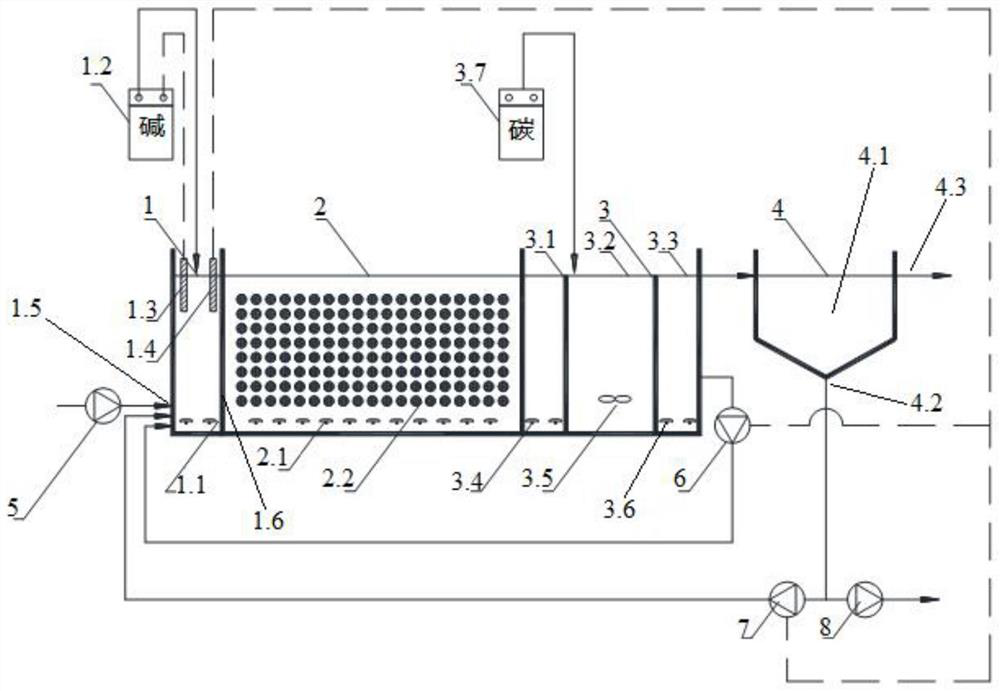

[0068] The coal chemical wastewater enters the high-load aeration tank first, and the refractory organic matter is removed in the high-load aeration tank. The effluent of the high-load aeration tank is figure 2 The shown device performs deep denitrification anaerobic ammonium oxidation, and the process is as follows:

[0069] The influent water (that is, the effluent from the high-load aeration tank) and the return sludge flowing out of the sedimentation tank 4.1 enter the pre-inhibition zone 1 and mix under the action of the first aeration system 1.1. The sludge return flow is 4000-8000m 3 / d, the ammonia nitrogen concentration in the pre-inhibition zone 1 is controlled at 200mg / L, no nitrification liquid return system is set (that is, the ammonia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com