Gelling agent for curing heavy metal ions in tailings and use method thereof

A technology of heavy metal ions and gelling agents, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as high cost of use, large amount of use, and high production cost

Pending Publication Date: 2021-05-28

SINOSTEEL MAANSHAN INST OF MINING RES +2

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The purpose of the present invention is to provide a method for solidifying heavy metal ions in tailings in view of the problems of high production cost, large amount of use, high cost of use and no consideration of the solidification and stabilization of heavy metals in tailings in the prior art. Gelling agent, used in tailings filling, tailings dry stacking or heavy metal pollution control in metallurgical dressing and smelting slag field, not only has excellent cementation performance, but also strengthens anti-carbonization and anti-acidolysis through various functions such as chelation Ability to maintain the stability of solidified heavy metal ions for a long time and avoid migration of heavy metal ions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

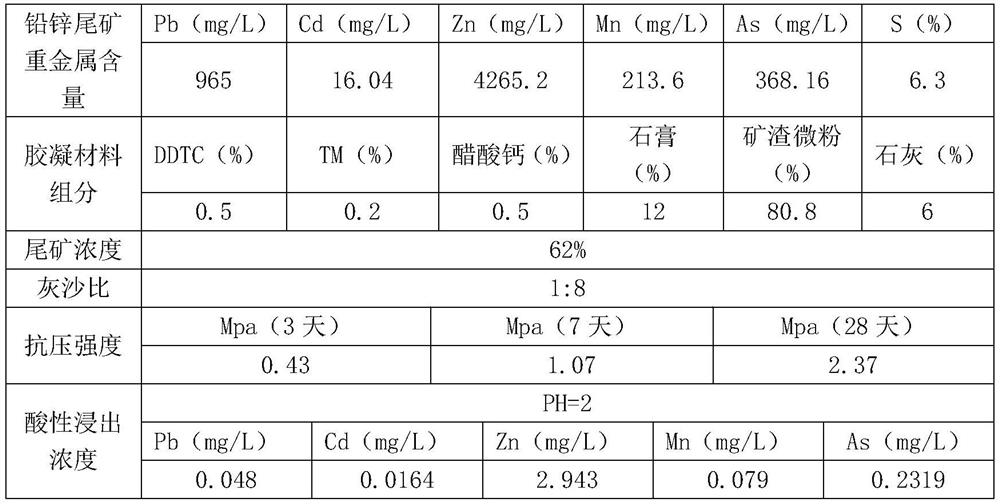

Embodiment 1

[0039]

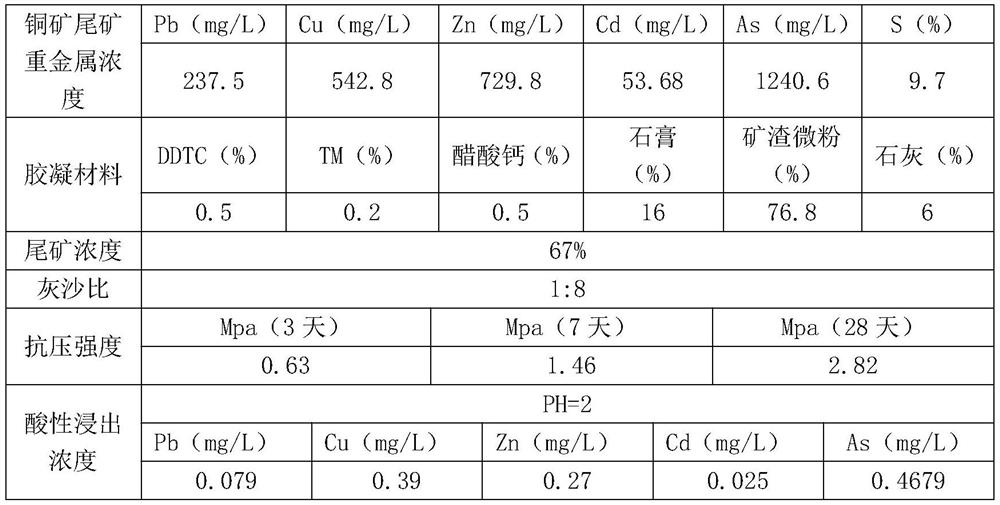

Embodiment 2

[0041]

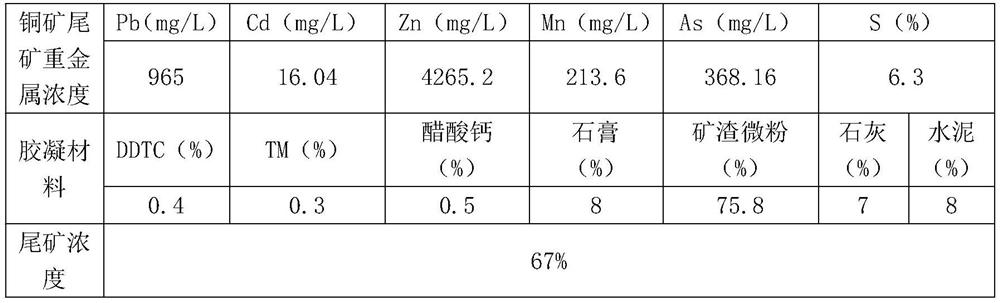

Embodiment 3

[0043]

[0044]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a gelling agent for solidifying heavy metal ions in tailings and a use method of the gelling agent. The gelling agent is prepared from the following raw materials in percentage by mass: 0.25-0.7% of a chelating trapping agent, 0.15-0.3% of a chelating accelerant, 0.2-0.6% of a complexing early strength agent, 1-7% of lime, 0-10% of cement, 8-20% of gypsum, 0-20% of steel slag micro powder and 50-82% of slag micro powder. The chelating trapping agent, the chelating accelerant and the complexing early strength agent are uniformly mixed, and then are uniformly mixed with other components. The gelling agent prepared by the invention not only can be used for cementing full tailings through hydration reaction to realize filling mining, but also can be used for synergistically curing heavy metal ions in the tailings through various effects of leaching, chelating, wrapping, chemical adsorption, chemical passivation, ion substitution and the like to keep the curing stability for a long time, and is especially suitable for cementing filling of full tailings with high heavy metal ion content, and the environmental risk of high content of heavy metal ions in the filling body after tailing filling is obviously reduced.

Description

technical field [0001] The invention belongs to the field of solid waste gelling material preparation technology, and specifically relates to a gelling agent for solidifying heavy metal ions in tailings, which can be used for solidifying and stabilizing heavy metal ions in tailings filling, and can also be used in tailings dry It is widely used in solidification and stabilization of heavy metal ions in heap and metallurgical dressing and slag field, especially suitable for solidification and stabilization of tailings containing harmful elements such as Pb, Cd, Zn, Mn and S. Background technique [0002] The development of mineral resources is one of the important ways for the continuous development of human beings and society. With the continuous exploitation of mineral resources, the pollution and damage to the ecological environment caused by metal tailings has become an important issue of global concern, especially the metal tailings. Heavy metal pollution has always been...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/14C04B28/16C04B24/16C04B18/14

CPCC04B28/141C04B28/145C04B28/16C04B24/16C04B18/142C04B18/141C04B2111/00775C04B2111/00724C04B2201/50C04B24/04C04B22/064C04B7/02Y02W30/91

Inventor 杨晓军徐修平华绍广刘龙于先坤

Owner SINOSTEEL MAANSHAN INST OF MINING RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com