High-orientation layered graphene aerogel phase change composite material and preparation method thereof

A phase-change composite material and graphene hydrogel technology, which is applied in the field of phase-change energy storage, can solve the problems of low density, graphene airgel is easily broken, and poor resilience, so as to improve thermal conductivity and excellent directional thermal conductivity Effect of performance, high energy storage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1. Take 10 mg / ml graphene oxide suspension in a polytetrafluoroethylene reactor, and use segmented heating to obtain a reduced graphene hydrogel. The whole process is divided into three steps, ① with 10°C / min to 180°C, after 120min of heat preservation, the sample is cooled to room temperature at a cooling rate of 5°C / min; ② After complete cooling, put it into a muffle furnace at 180°C for 120min, take out the sample and cool to room temperature; ③ After it is completely cooled, put it into a muffle furnace at 180°C for 120 minutes, and cool the sample to room temperature at a cooling rate of 5°C / min.

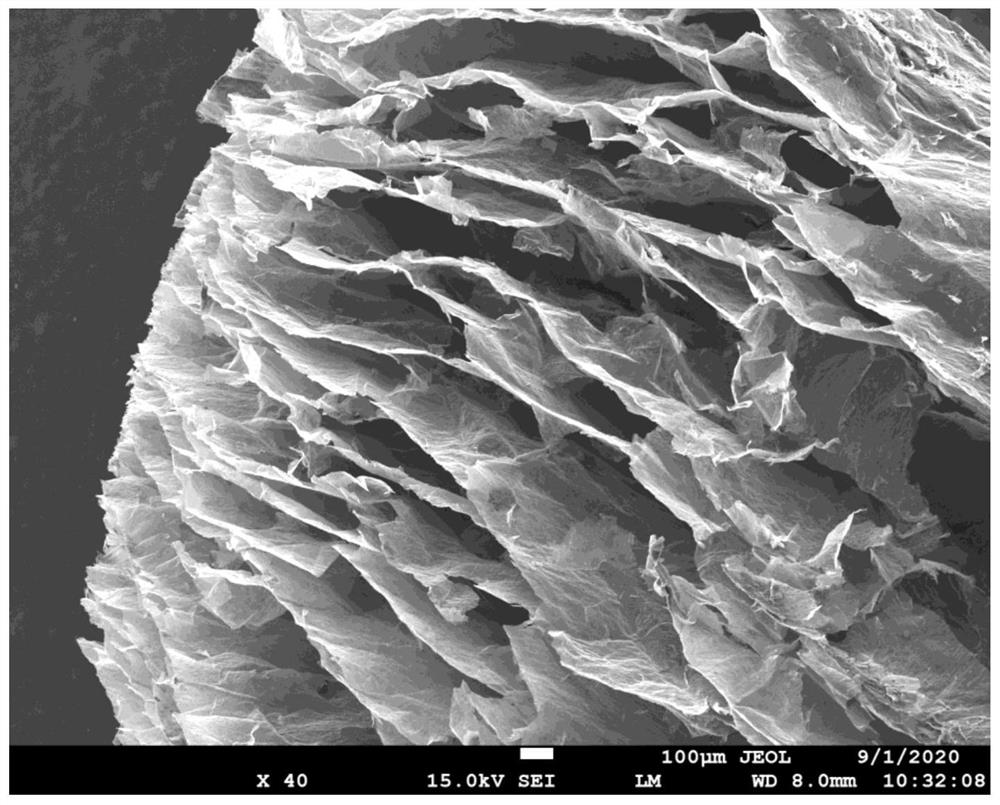

[0042] Step 2. Pre-freeze the hydrogel obtained in step 1 in the cold hydrazine of a freeze dryer to ensure that the ice crystals inside the hydrogel grow completely. The pre-freezing temperature is -10°C and the pre-freezing time is 2 hours.

[0043] Step 3. Take out the sample in step 2 and carry out vacuum freeze-drying to obtain a highly oriented layered airgel ...

Embodiment 2

[0050] Step 1. Take 10 mg / ml graphene oxide suspension in a polytetrafluoroethylene reactor, and use segmented heating to obtain a reduced graphene hydrogel. The whole process is divided into three steps, ① with 8°C / min to 180°C, after 100min of heat preservation, the sample is cooled to room temperature at a cooling rate of 3°C / min; ② After complete cooling, put it in a muffle furnace at 180°C for 100min, take out the sample and cool to room temperature; ③ After it is completely cooled, put it into a muffle furnace at 180°C for 100 minutes, and cool the sample to room temperature at a cooling rate of 3°C / min.

[0051] Step 2. Pre-freeze the hydrogel obtained in step 1 in the cold hydrazine of a freeze dryer to ensure that the ice crystals inside the hydrogel grow completely. The pre-freezing temperature is -15° C. and the pre-freezing time is 4 hours.

[0052] Step 3. Take out the sample in step 2 and carry out vacuum freeze-drying to obtain a highly oriented layered airgel m...

Embodiment 3

[0057] Step 1. Take 10 mg / ml graphene oxide suspension in a polytetrafluoroethylene reactor, and use segmented heating to obtain a reduced graphene hydrogel. The whole process is divided into three steps, ① with 10°C / min to 180°C, after holding for 60 minutes, the sample is cooled to room temperature at a cooling rate of 1°C / min; ② After complete cooling, put it into a muffle furnace at 180°C for 60 minutes, take out the sample and cool to room temperature; ③ After it is completely cooled, put it into a muffle furnace at 180°C for 60 minutes, and cool the sample to room temperature at a cooling rate of 1°C / min.

[0058] Step 2. Pre-freeze the hydrogel obtained in step 1 in the cold hydrazine of a freeze dryer to ensure that the ice crystals inside the hydrogel grow completely. The pre-freezing temperature is -20° C. and the pre-freezing time is 6 hours.

[0059] Step 3. Take out the sample in step 2 and carry out vacuum freeze-drying to obtain a highly oriented layered airgel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

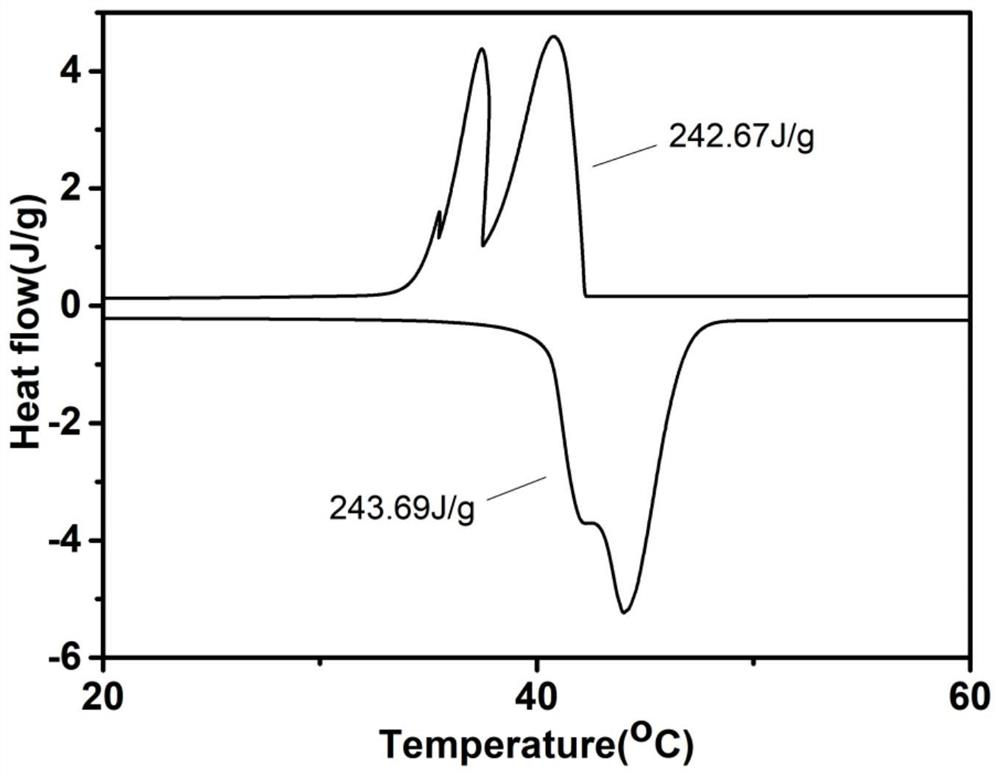

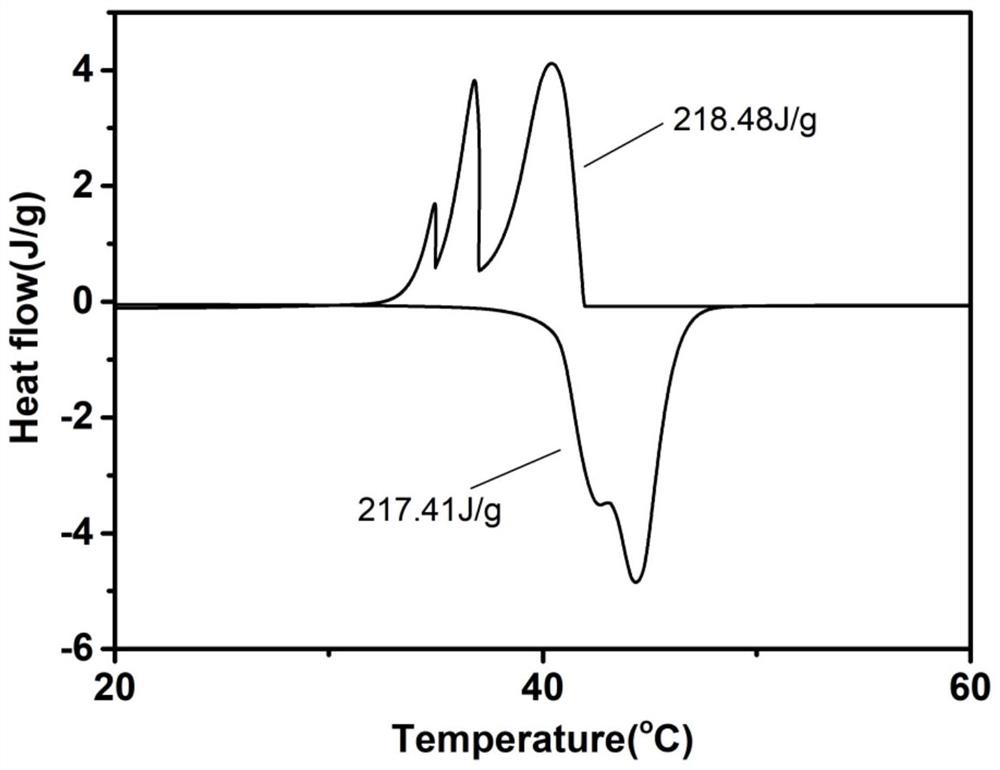

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com