Preparation method of cream base paper

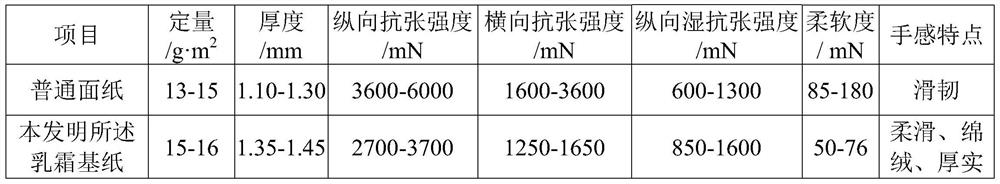

A technology of base paper and cream, which is applied in the field of papermaking, can solve the problems of smoothness, wettable water-based velvet and thick performance that are not obvious enough, and cannot be used as a spray carrier for cream paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of cream base paper, the method comprises the following steps:

[0038] (1) 3 packs of softwood pulp imported from North America (air-dry weight 230kg / pack), 2 packs of hardwood pulp imported from Brazil (air-dry weight 250kg / pack), and 4 packs of softwood pulp imported from North America (air-dry weight 230kg / pack) and imported from Brazil 1 bag of hardwood pulp (air-dry weight 250kg / bag) is put into the long-fiber pulper by feeding at intervals, adding 0.25kg / t CMC, adding white water to a concentration of 6.5ωt%, and then crushing. The crushing time is 12 minutes, and then Pumped into the long fiber pulp pool;

[0039] (2) 5 bags of hardwood pulp imported from Brazil (air-dry weight 250kg / bag) are put into a short fiber pulper, add 0.28kg / t CMC, add white water to a concentration of 6.5ωt%, and then disintegrate. The disintegration time is 10 minutes. Afterwards, it is pumped into the pulp tank before the staple fiber tap;

[0040](3) Add water...

Embodiment 2

[0048] A preparation method of cream base paper, the method comprises the following steps:

[0049] (1) 3 packs of softwood pulp imported from North America (air-dry weight 230kg / pack), 2 packs of hardwood pulp imported from Brazil (air-dry weight 250kg / pack), and 4 packs of softwood pulp imported from North America (air-dry weight 230kg / pack) and imported from Brazil 1 bag of hardwood pulp (air dry weight 250kg / bag) is put into the long-fiber pulper by feeding at intervals, add 0.22kg / t CMC, add white water to a concentration of 6.0ωt%, and then disintegrate. The disintegration time is 15 minutes, and then Pumped into the long fiber pulp pool;

[0050] (2) 5 bags of hardwood pulp imported from Brazil (air-dried weight 250kg / bag) are put into a short fiber pulper, add 0.26kg / t CMC, add white water to a concentration of 6.0ωt%, and then disintegrate. The disintegration time is 12 minutes. Afterwards, it is pumped into the pulp tank before the staple fiber tap;

[0051] (3) Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com