Measuring device and operation method for coating internal stress

A technology for measuring devices and operating methods, applied in hydraulic/pneumatic metering, cells, electrolytic components, etc., to achieve the effects of improved electroplating performance, simple structure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

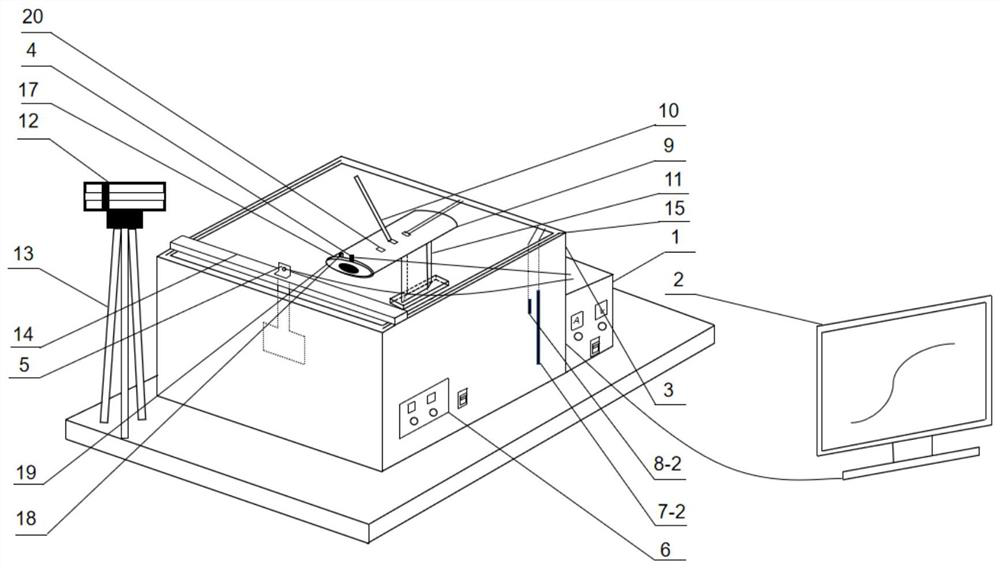

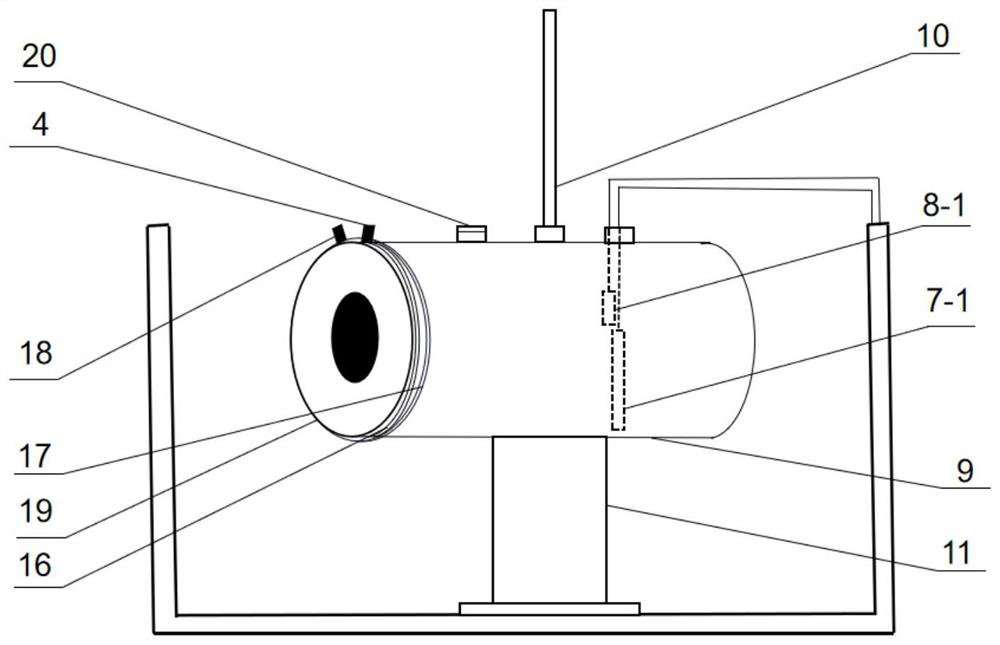

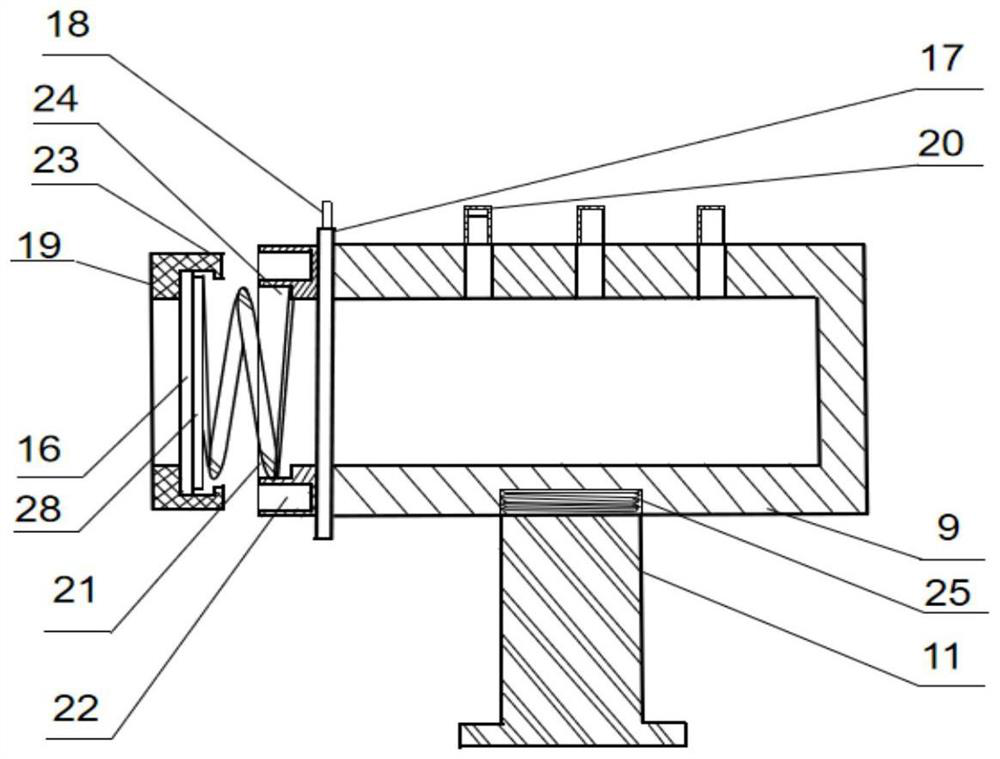

Embodiment 1

[0045] A circular sample of copper material with a thickness of 0.5 mm and a diameter of 30 mm is used as the cathode 4 to electroplate Watt nickel, and measure the change curve of the internal stress of the coating during the electroplating Watt nickel process.

[0046] (1) Set the temperature of the plating solution and the working solution to 55°C, turn on the camera 12 and the computer 2, adjust the electrode plate 14 so that the distance between the anode plate 5 and the cathode 4 is 5cm, and set the camera 12 to take pictures at a time interval of 0.5s , prepare the copper sample for pretreatment;

[0047] (2) Quickly clamp the sample, check whether the working fluid is full from the liquid replenishment port 20, connect the anode plate 5 and the cathode 4 to the positive and negative poles of the power supply device 1 respectively, turn on the power supply device 1, and set the current to 0.2A, Plating time is 20min;

[0048] (3) The internal stress generated by electr...

Embodiment 2

[0050] A steel material, a square sample with a thickness of 0.1mm and a side length of 40mm is used as the cathode 4, electroplated with hexavalent chromium, and measuring the change curve of the internal stress of the coating during the chromium electroplating process.

[0051] (1) The temperature of the plating solution and the working solution is set to 50°C, the camera 12 and the computer 2 are turned on, the electrode plate 14 is adjusted so that the distance between the anode plate 5 and the cathode 4 is 4.5 cm, and the time interval of taking pictures of the camera 12 is 0.5 cm. s, prepare the steel sample for pretreatment;

[0052] (2) Quickly clamp the sample, check whether the working fluid is full from the liquid replenishment port 20, connect the anode plate 5 and the cathode 4 to the positive and negative poles of the power supply device 1 respectively, turn on the power supply device 1, and set the current to 0.4A, Plating time is 40min;

[0053] (3) The intern...

Embodiment 3

[0055] Electroless copper plating is carried out on a plastic circular material sample with a thickness of 0.05mm and a diameter of 25mm, and the change curve of the internal stress of the coating during the electroless copper plating process is measured.

[0056] (1) The temperature of the plating solution and the working solution is set to 45° C., the camera 12 and the computer 2 are turned on, the camera 12 is set to take pictures at a time interval of 0.5 s, and the plastic sample is prepared for pretreatment;

[0057] (2) Quickly clamp the sample, check whether the working fluid is full from the liquid replenishment port 20, without turning on the power supply device 1, without connecting the positive and negative electrodes of the power supply device 1, and the electroplating time is 50 minutes;

[0058] (3) The internal stress produced by the electroless plating deforms the substrate. The camera 12 monitors the liquid level of the capillary 10. After processing by the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com