New energy automobile battery pack heat dissipation device

A technology for new energy vehicles and cooling devices, which is applied to battery pack components, secondary batteries, circuits, etc., and can solve problems such as damaging the battery, affecting the service life of the battery, cooling efficiency, and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

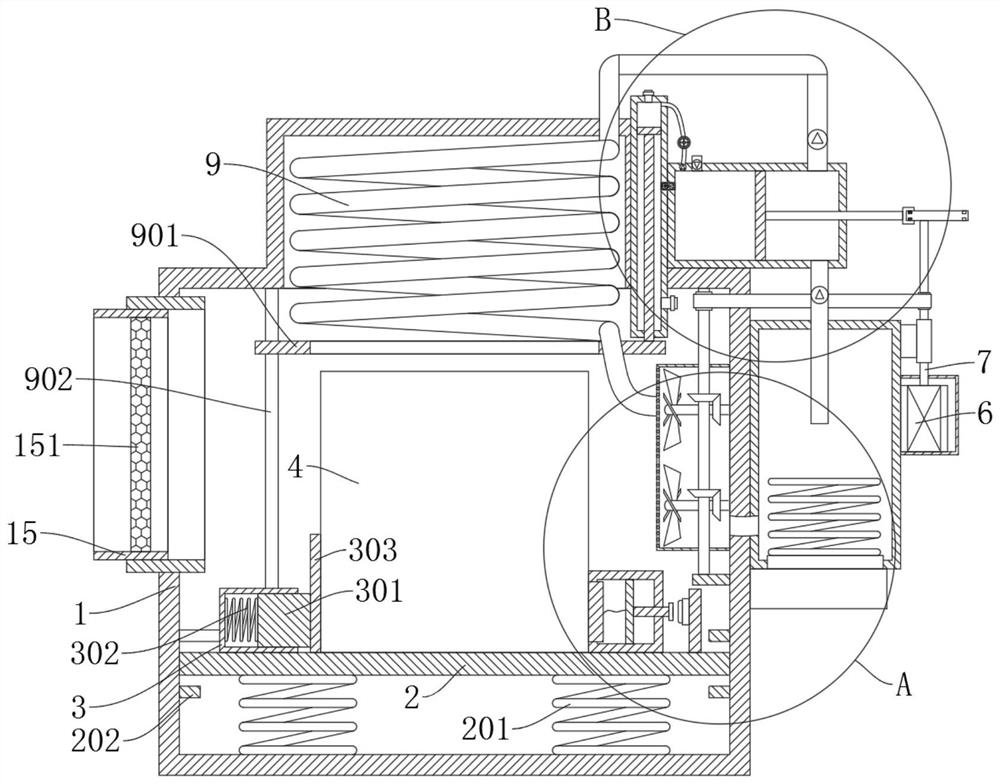

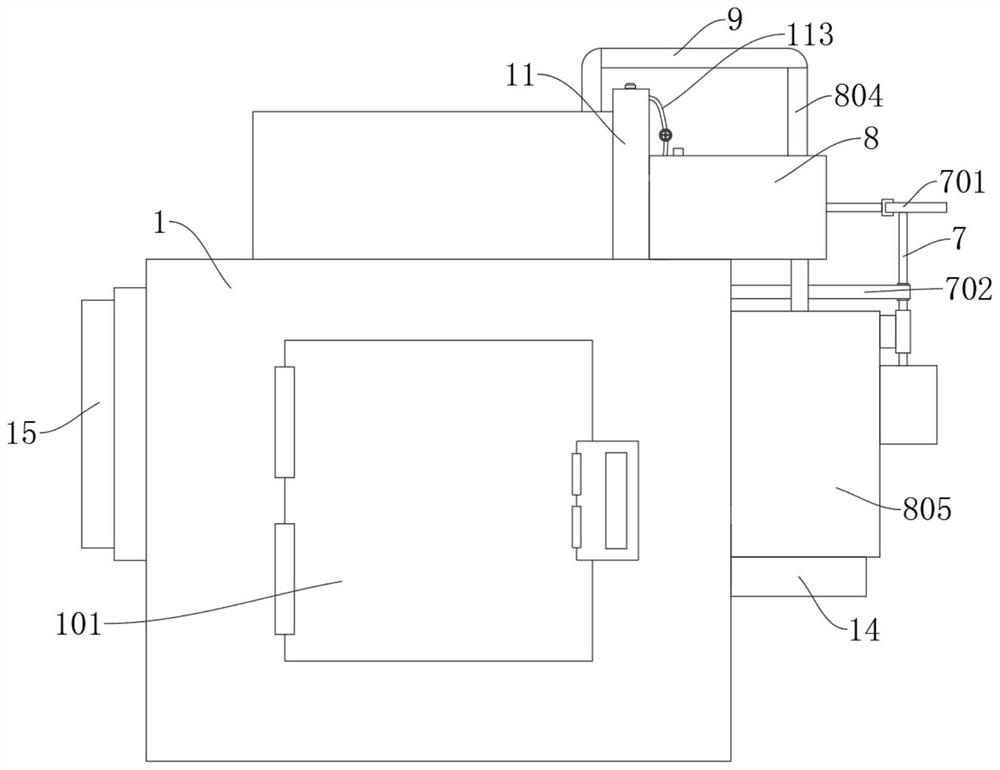

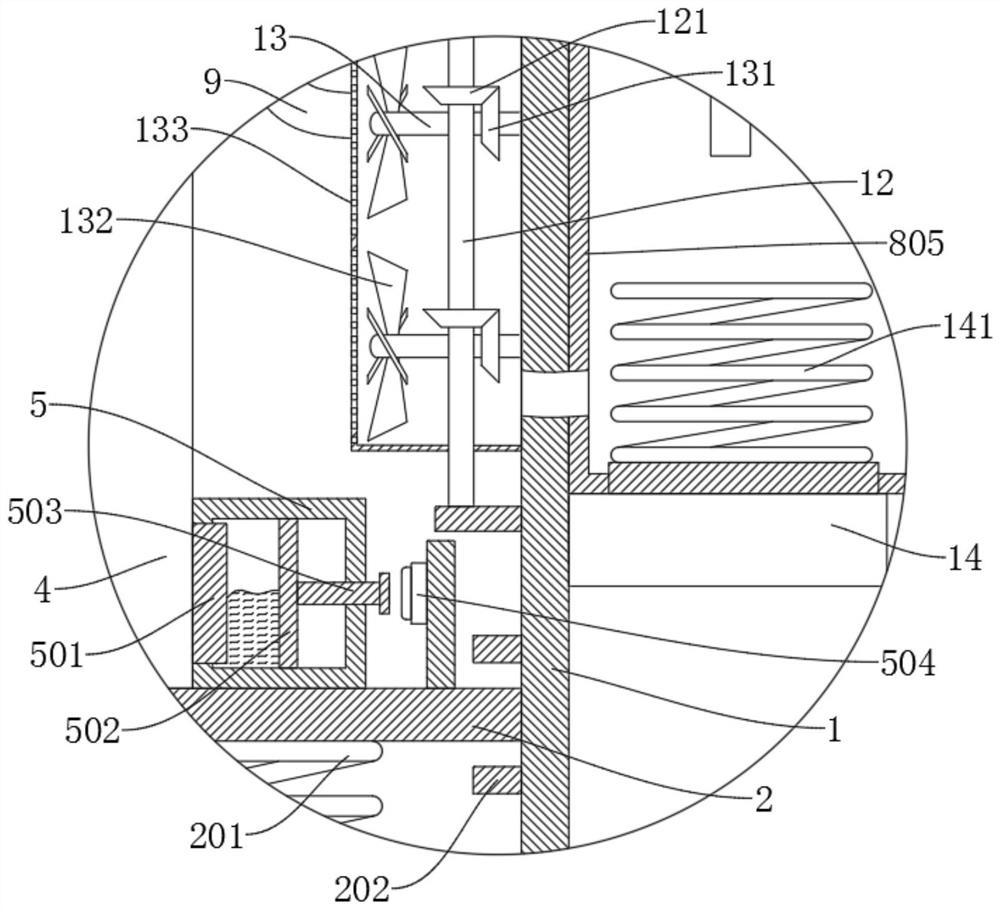

[0038] refer to Figure 1-6 , a heat dissipation device for a new energy vehicle battery pack, comprising a box body 1, a shock absorbing plate 2 is slidably connected to the box body 1, and a first spring 201 is fixedly connected to the bottom of the shock absorbing plate 2, and the first spring 201 is far away from the shock absorbing plate 2 One end is fixedly connected to the inner wall of the box body 1, and the shock absorbing plate 2 is respectively provided with a battery device 4, a clamping mechanism for fixing the battery device 4, and a heat dissipation control mechanism, and the side wall of the box body 1 is provided with a water tank 805, and the water tank 805 The side wall is provided with a driving motor 6, the output end of the driving motor 6 is fixedly connected with the first rotating shaft 7, the first rotating shaft 7 is provided with a cam 701, the side wall of the box body 1 is provided with a cylinder 8, and a piston 801 is slidingly connected in the ...

Embodiment 2

[0041] refer to Figure 1-6 , a heat sink for a battery pack of a new energy vehicle, which is basically the same as that of Embodiment 1, furthermore, the clamping mechanism includes a clamping groove 3, and a clamping rod 301 is slidably connected to the clamping groove 3, and the clamping rod 301 is located at One end in the clamping groove 3 is fixedly connected with a second spring 302, and one end of the second spring 302 away from the clamping rod 301 is fixedly connected to the inner wall of the clamping groove 3, and one end of the clamping rod 301 away from the second spring 302 is fixedly connected with The arrangement of the clamping plate 303 , the clamping groove 3 , the clamping rod 301 , the second spring 302 and the clamping plate 303 is convenient for clamping and fixing the battery device 4 .

Embodiment 3

[0043] refer to Figure 1-6 , a heat dissipation device for a battery pack of a new energy vehicle, which is basically the same as that of Embodiment 1. Further, the heat dissipation control mechanism includes a control tube 5 and a control switch 504, and a heat conduction block 501 is provided on the side wall of the control tube 5, and the heat conduction block 501 and the The battery equipment 4 is attached to each other, a slide plate 502 is slidably connected in the control tube 5, and a pressure bar 503 is fixedly connected to the slide plate 502. The pressure bar 503 matches the control switch 504, and an expansion body is arranged between the heat conducting block 501 and the slide plate 502. After the temperature rises in the working process of the equipment 4, the temperature is transferred to the control tube 5 by the heat conduction block 501, so that the expansion body is heated and expanded to push the sliding plate 502 to slide, and then the pressure rod 503 pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com