Integrated damping winding, rotor and motor

An integrated technology of damping windings, applied in the field of rotors and motors, can solve the problems of broken damping strips, poor force capacity of a single damping strip, and affecting the service life of damping strips, etc., to achieve easy access, convenient cooling, and increased force capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

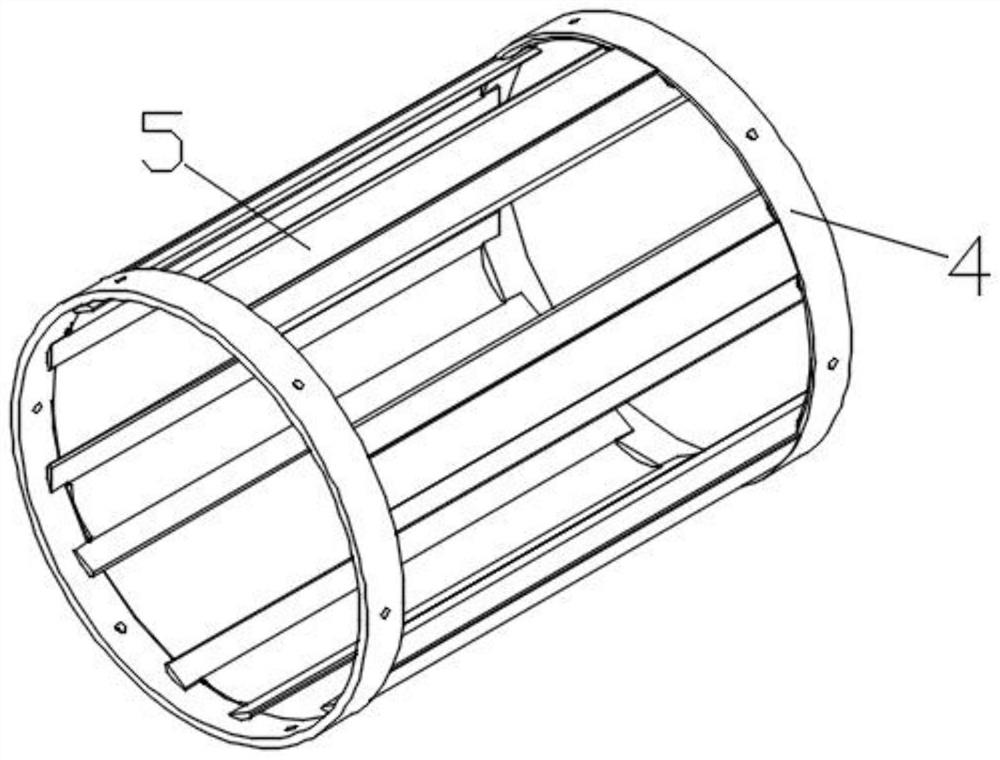

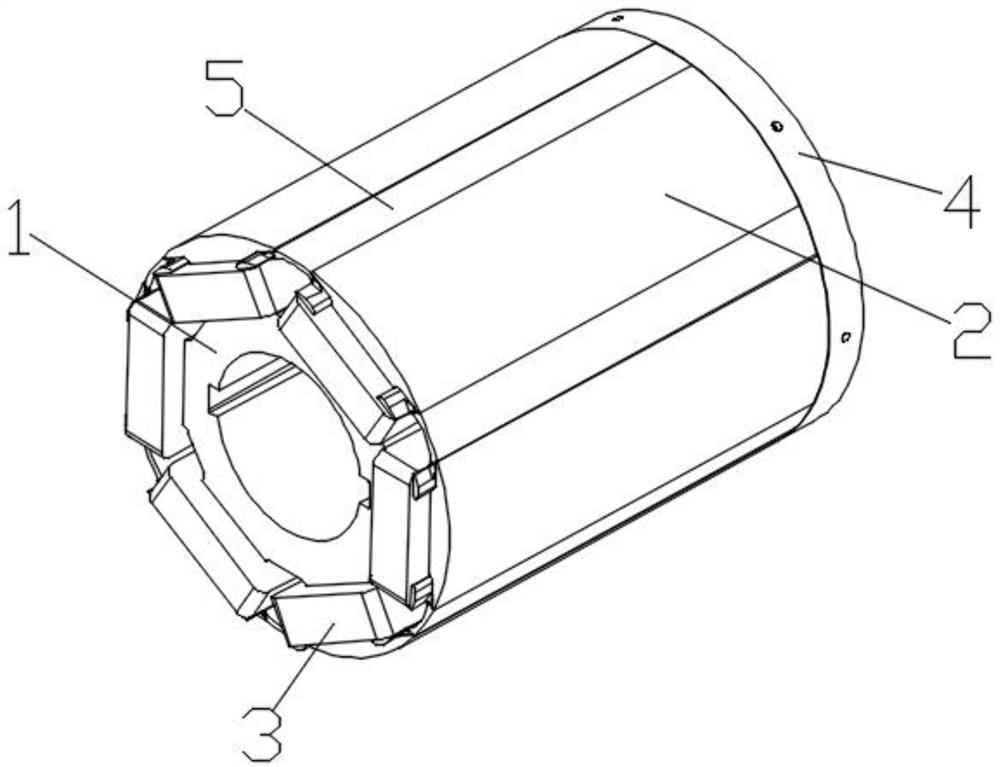

[0037] Such as figure 2As shown, this embodiment provides an integrated damping winding, including two short-circuit connectors 4 arranged at intervals and at least two integrated damping strips 5 connecting the two short-circuit connectors 4 to realize integrated damping strips 5 For the electrical connection with the short-circuit connector 4 , all the integrated damping strips 5 are arranged circumferentially along the radial direction of the short-circuit connector 4 . The integrated damping strip 5 is made of conductive soft magnetic material.

[0038] The conductive soft magnetic material is martensitic stainless steel or electrical steel. Martensitic stainless steel includes 17-4PH type and 410 type, of which 17-4PH type includes 17-4PH H900 and 17-4PH H1150, and electrical steel includes M235-35A. Such as Figure 6 As shown, the BH characteristic of M235-35A material corresponds to linear I, the BH characteristic of 17-4PH H900 material corresponds to linear II, and ...

Embodiment 2

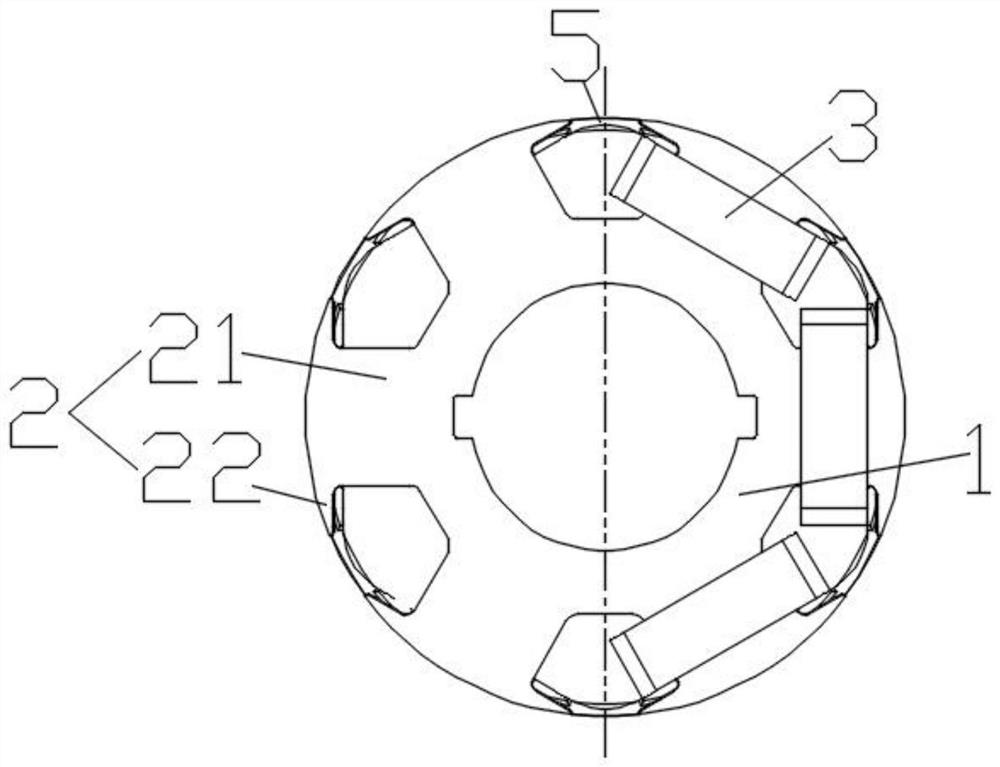

[0043] Such as figure 1 As shown, this embodiment discloses a rotor, including a rotor core 1 and an integrated damping winding in Embodiment 1. The rotor core 1 is provided with a shaft hole for installing a rotating shaft, and the rotating shaft is installed through the shaft hole. On the rotor; rotor core 1 is provided with an even number of rotor poles 2, each rotor pole 2 is provided with excitation winding 3, integrated damping strips 5 are arranged between rotor poles 2, and short-circuit connectors 4 are respectively arranged on The front and rear ends of the rotor core 1.

[0044] In this embodiment, the material of the rotor core 1 is M235-35A, and the material of the integrated damping strip 5 is 17-4PHH900. Such as Figure 6 As shown, the BH characteristic of M235-35A material corresponds to linear I, and the BH characteristic of 17-4PH H900 material corresponds to linear II. The magnetic field strengths of 6000 amperes per meter, 8000 amperes per meter, 10000 a...

Embodiment 3

[0052] This embodiment discloses a generator, which is a 250kVA generator, which includes a stator and a rotor using an integrated damping winding in Embodiment 2. The rotor core 1 is made of M235-35A material, and the material of the integrated damping strip 5 is 17-4PH H900. On the premise that the stator adopts the stator inclined groove technology, according to the test method of GBT1029-2005, the experiments were carried out at 500r / min, 1000r / min, 1500r / min and 3000r / min, and the experimental results are as follows Figure 7-10 shown. Figure 7-10 They are the comparison charts of the simulation value of the output voltage of the integrated damping winding rotor at 500r / min, 1000r / min, 1500r / min and 3000r / min respectively and the experimental test data. The solid line marked a in the figure is the experimental data, and the mark b The dotted line is the simulated data. It can be seen from the figure that under the speed range of 500-3000r / min, the generator complies wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com