Industrialized seedling transplanting and under-mulch fine management method for fresh corn

A fine-grained management and fresh-eating corn technology, which is applied in the field of fresh-eating corn industrialized seedling cultivation and transplanting and fine management under film, can solve the problems of inconsistent plant emergence, waste of water resources, high labor costs, etc., and improve planting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

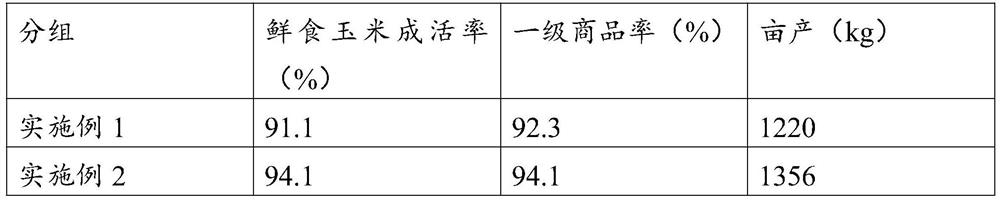

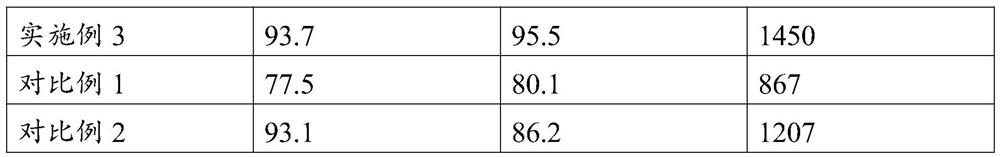

Embodiment 1

[0074] A method for industrialized seedling cultivation and transplanting of fresh corn and fine management under film, comprising the following steps:

[0075] (1) Furrowing: Select a suitable field, the depth of machine plowing is 30cm, the furrow distance is 40cm, the moisture surface is 95cm, and the moisture height is 20-30cm;

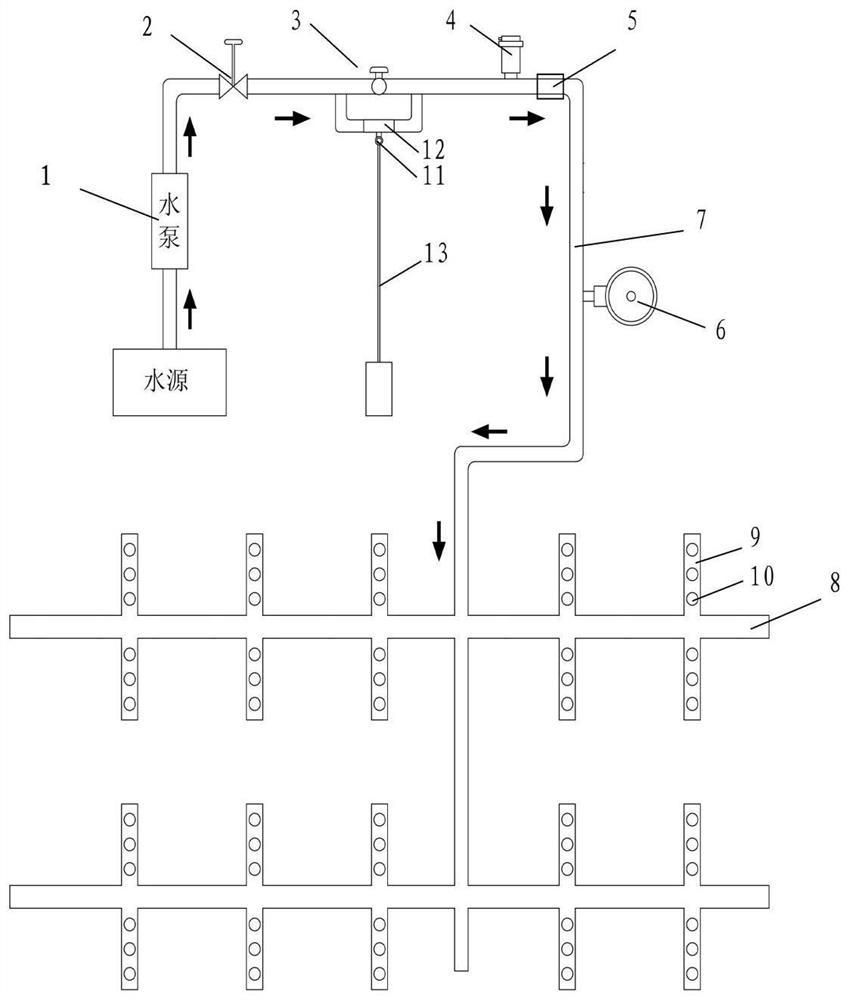

[0076] (2) Lay the irrigation system: the dropper system includes a water pump 1, a one-way valve 2, a Venturi fertilizer applicator with a ball valve 3, an exhaust valve 4, a filter 5, a pressure gauge 6, and a main pipe 7; one end of the water pump 1 is connected to the water source, and the other One end is connected to check valve 2, Venturi fertilizer applicator with ball valve 3, exhaust valve 4, filter 5 and pressure gauge 6 in turn through the main pipe 7, and then leads to the field;

[0077] (3) Field layout: The pipelines leading into the field are divided into four grades of pipelines, including the main pipe 7, and also include the ma...

Embodiment 2

[0100] A method for industrialized seedling cultivation and transplanting of fresh corn and fine management under film, comprising the following steps:

[0101] (1) ditching: select suitable fields, the depth of machine plowing is 33cm, the furrow distance is 42cm, the soil moisture surface is 98cm, and the soil moisture is high at 25cm;

[0102] (2) Lay the irrigation system: the dropper system includes a water pump 1, a one-way valve 2, a Venturi fertilizer applicator with a ball valve 3, an exhaust valve 4, a filter 5, a pressure gauge 6, and a main pipe 7; one end of the water pump 1 is connected to the water source, and the other One end is connected to check valve 2, Venturi fertilizer applicator with ball valve 3, exhaust valve 4, filter 5 and pressure gauge 6 in turn through the main pipe 7, and then leads to the field;

[0103] (3) Field layout: The pipelines leading into the field are divided into four grades of pipelines, including the main pipe 7, and also include ...

Embodiment 3

[0126] A method for industrialized seedling cultivation and transplanting of fresh corn and fine management under film, comprising the following steps:

[0127] (1) ditching: select suitable fields, the depth of machine plowing is 35cm, the furrow distance is 45cm, the soil moisture surface is 100cm, and the soil moisture is high 30cm;

[0128] (2) Lay the irrigation system: the dropper system includes a water pump 1, a one-way valve 2, a Venturi fertilizer applicator with a ball valve 3, an exhaust valve 4, a filter 5, a pressure gauge 6, and a main pipe 7; one end of the water pump 1 is connected to the water source, and the other One end is connected to check valve 2, Venturi fertilizer applicator with ball valve 3, exhaust valve 4, filter 5 and pressure gauge 6 in turn through the main pipe 7, and then leads to the field;

[0129] (3) Field layout: The pipelines leading into the field are divided into four grades of pipelines, including the main pipe 7, and also include th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com