Preparation process of soda water with white peach flavor

A soda water and white peach technology, applied in food ingredients as taste improvers, transportation, packaging, dissolution, etc., can solve the problem of single taste of soda water, achieve rich tasting experience, facilitate processing, and optimize mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

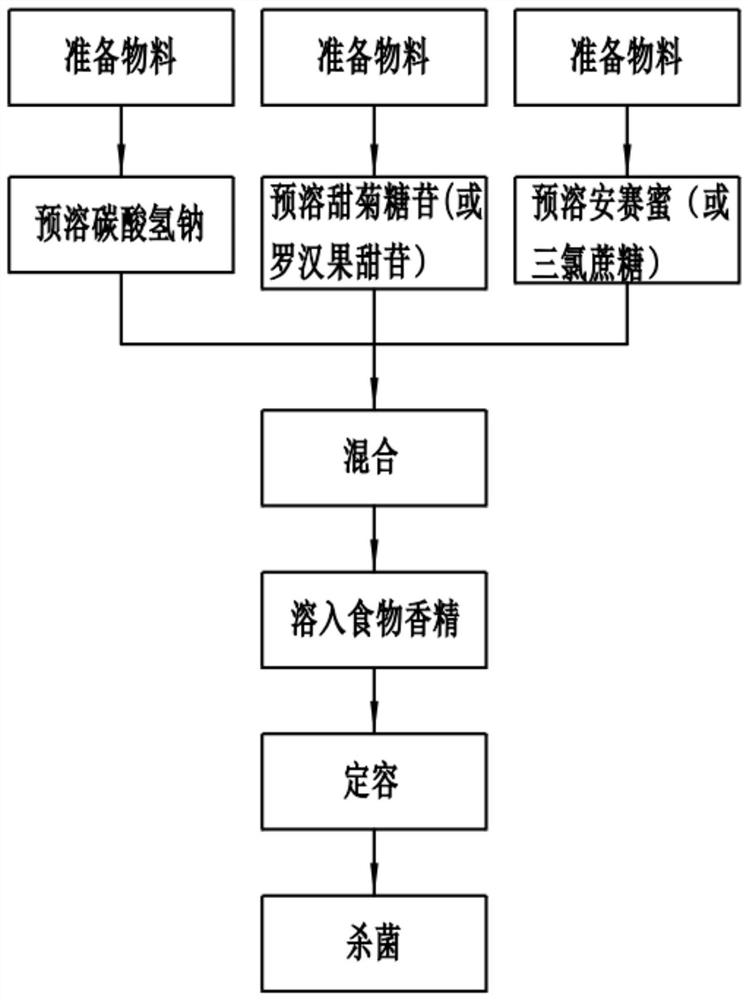

[0041] Basic as attached figure 1 Shown: a kind of white peach flavor soda water configuration process, comprises the following steps:

[0042] Step 1, prepare materials, including the deployment of water, sodium bicarbonate, steviol glycoside, sucralose and food flavor; wherein the deployment of 995 parts of water, 1 part of sodium bicarbonate, 0.15 parts of stevioside, 0.15 parts of sucralose, edible Essence 4.75 parts.

[0043] Step 2, pre-dissolving sodium bicarbonate, preparing the first pre-dissolving bucket 1, dissolving sodium bicarbonate in 180L of preparation water, and using the first agitator 5 to stir;

[0044] Step 3, pre-dissolving steviol glycosides, preparing a second pre-dissolving tank 2, dissolving steviosides in 180L of prepared water, and using the second agitator 6 to stir;

[0045] Step 4, pre-dissolving the sucralose, preparing the third pre-dissolving tank 3, dissolving the sucralose in 180L of prepared water, and using the third agitator 7 to stir;...

Embodiment 2

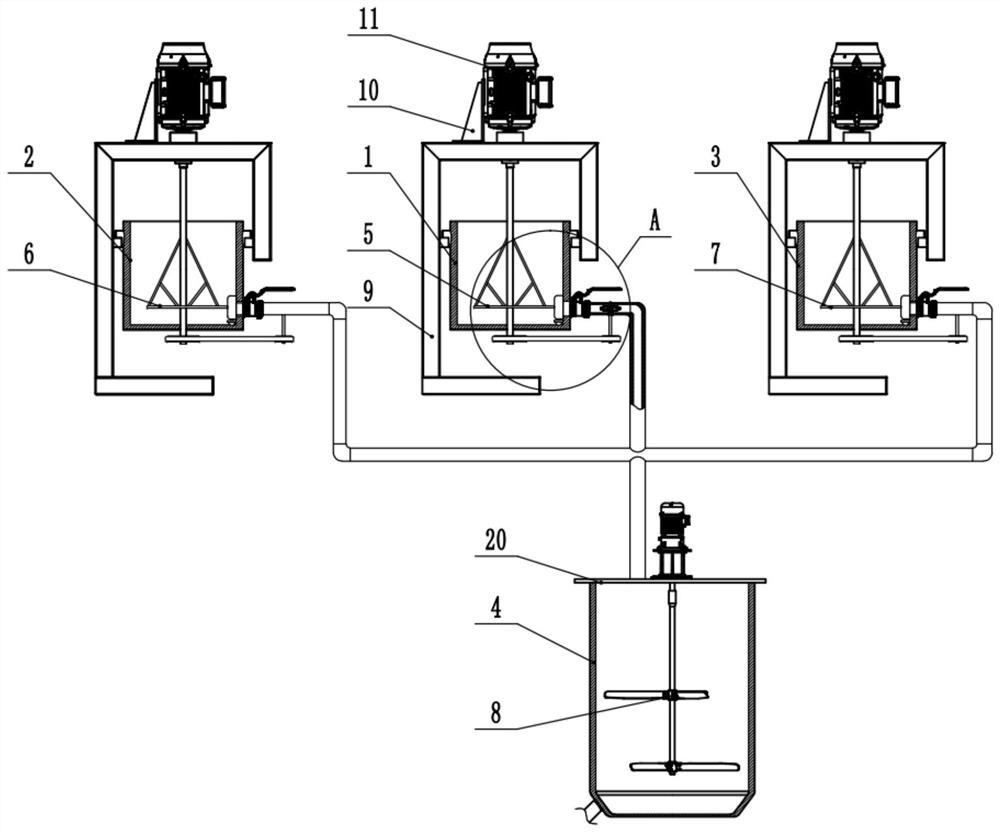

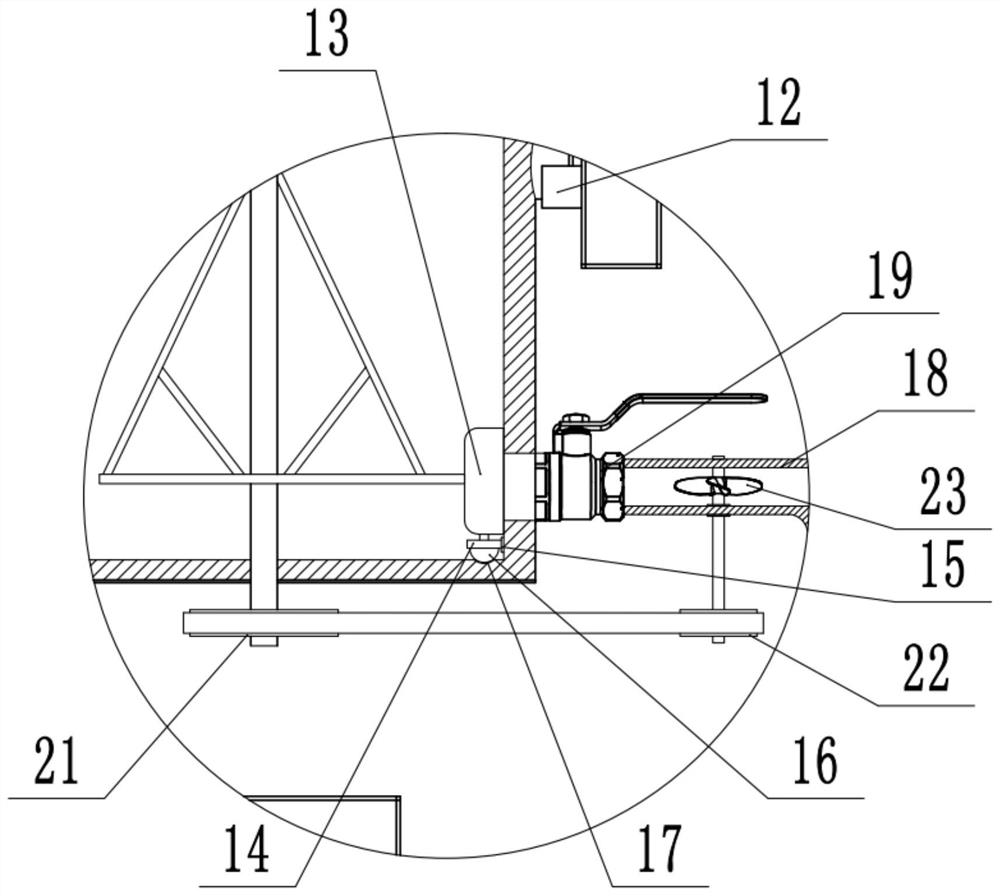

[0052] The difference between this embodiment and Embodiment 1 is that, as attached figure 2 with attached image 3 As shown, the first pre-dissolution tank 1, the second pre-dissolution tank 2 and the third pre-dissolution tank 3 and their matching mechanisms are the same. Wherein the first pre-dissolving barrel 1 is a drum-shaped structure, and also includes a support frame 9, the top bolt of the support frame 9 is fixed with a reinforcement 10, and the right side wall bolt of the reinforcement 10 is fixed with a first drive motor 11, the first drive The drive shaft of the motor 11 is vertically facing downwards. Trays 12 are respectively welded and fixed on the left and right sides of the inner wall of the support frame 9, and the first pre-dissolution barrel 1 is rotatably connected between the two trays 12, and the top of the first pre-dissolution barrel 1 is open. The output shaft of the first drive motor 11 is coaxially keyed and fixed with the first agitator 5 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com