A voc gas electrosorption-catalytic degradation device and process

A catalytic degradation and electro-adsorption technology, which is applied in gas treatment, air quality improvement, chemical instruments and methods, etc., can solve the problems of unsatisfactory treatment effect, difficult to popularize in ordinary households, and limited degradation effect, so as to improve VOC degradation efficiency, The effect of low voltage requirements, application conditions and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

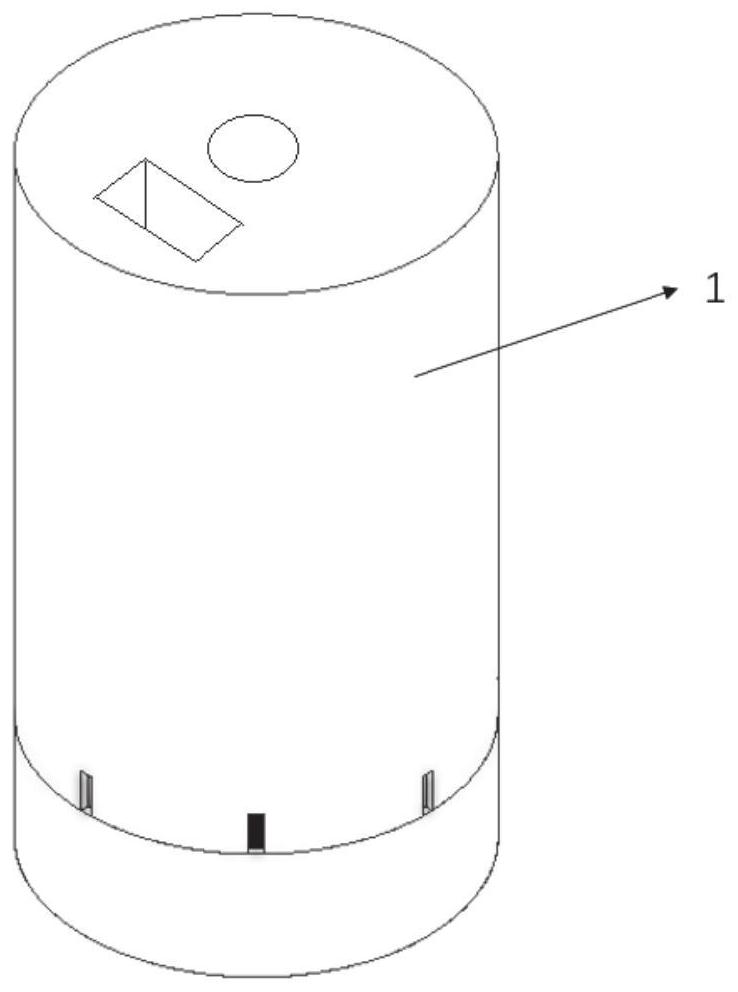

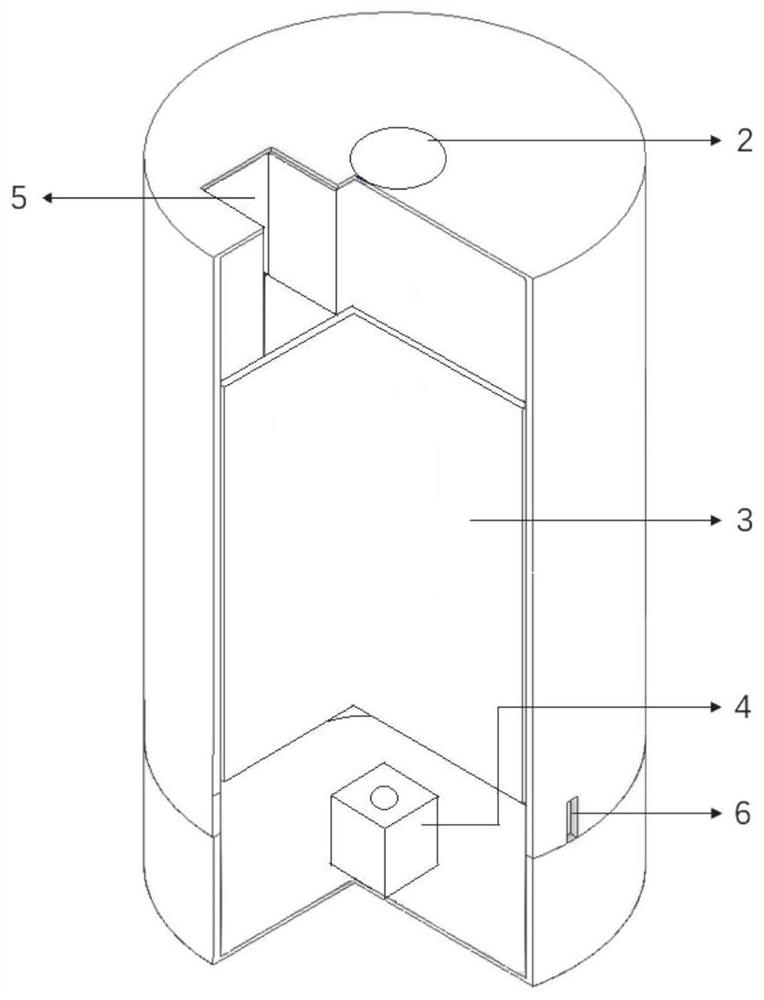

[0051] Such as figure 1 and figure 2 As shown, this embodiment provides a VOC gas electrosorption-catalytic degradation device, which mainly includes a housing 1, a fan 2, a main reactor 3 and a humidifier 4;

[0052] The housing 1 is in the shape of a cylinder, and the numerical control module 1 and the fan 2 are embedded on the top of the housing, wherein the fan 2 is located at the center of the top; the middle section of the housing 1 is provided with a main reactor 3, and a humidifier 4 is provided directly below the main reactor 3. Air intake holes 6 are arranged on the shell along the outer periphery of the bottom of the main reactor 3. Under the action of the blower fan 2, the air polluted by VOC enters the device from the air intake holes 6, and the air entering from the air intake holes 6 is combined with the humidification. The water vapor generated by the reactor 4 enters the main reactor 3 for adsorption-electrocatalytic degradation, and then is discharged from ...

Embodiment 2

[0055] On the basis of Embodiment 1, two VOC sensors are arranged on the front and rear sides of the main reactor 3, and are located on the same vertical line; the VOC sensor is also connected to the numerical control module 5, and the VOC sensor transmits the data obtained by monitoring to the numerical control module 5. The numerical control module 5 adjusts the power supply voltage after collecting data to control the VOC degradation rate in real time.

Embodiment 3

[0057] This embodiment provides a process for VOC gas electrosorption-catalytic degradation using the device in Embodiment 2, specifically: first turn on the fan 2 to generate a vacuum at the top of the device, and the air polluted by VOC is introduced through the air inlet 5 Inside the device, the humidifier 4 generates water vapor, which enters the main reactor 3 together with the VOC-contaminated gas. The functional carbon material layer 8 in the main reactor 3 absorbs the water vapor and the VOC gas in the air polluted by VOC. The electrocatalytic oxidation degradation reaction is carried out under the external power supply controlled by the numerical control module 5; when the VOC sensor detects that the VOC content in the air reaches the standard, the signal is transmitted to the numerical control module 5, and the numerical control module 5 controls the external power supply to turn off, the reaction is over, and the air is clean It is drawn out of the device by the fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com