Crushing and sorting device for waste building structures

A structure and sorting technology, applied in grain processing and other directions, can solve the problems affecting the sorting of structures, poor pulverization effect, and inadequate treatment of structures, and achieve the effect of ensuring grinding and pulverizing effect, convenient operation, and avoiding accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

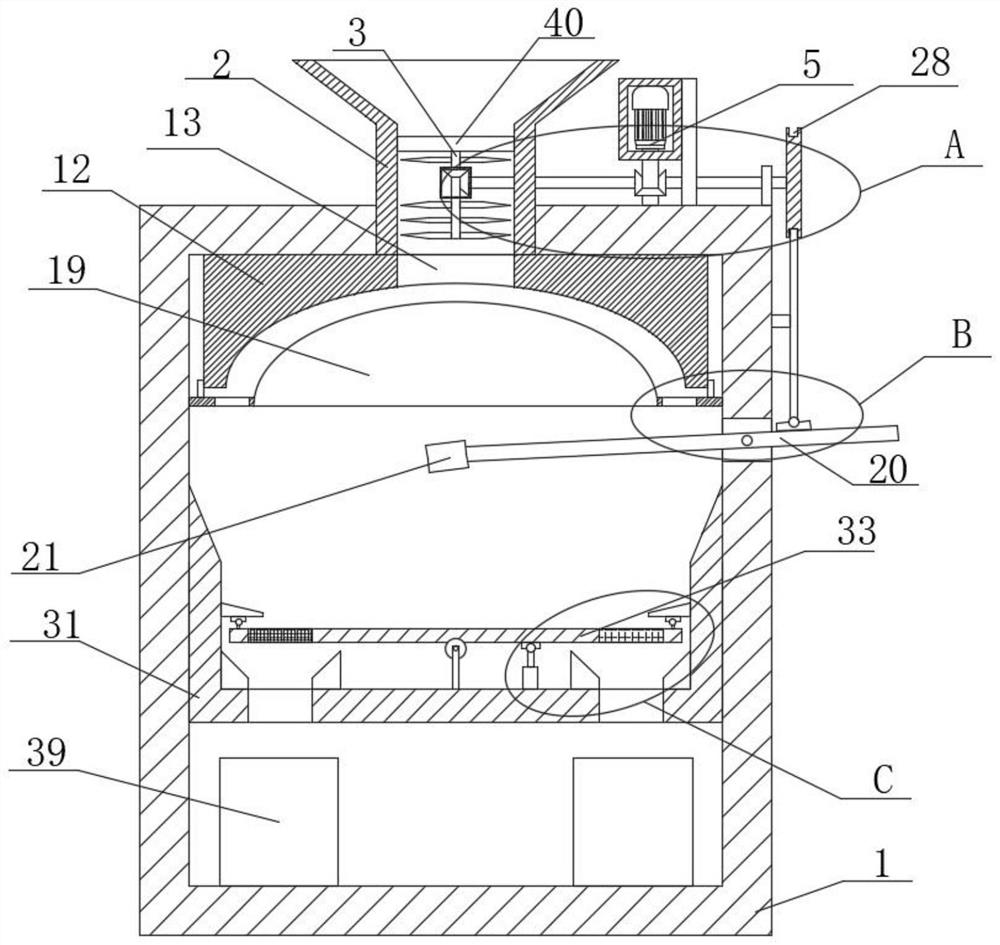

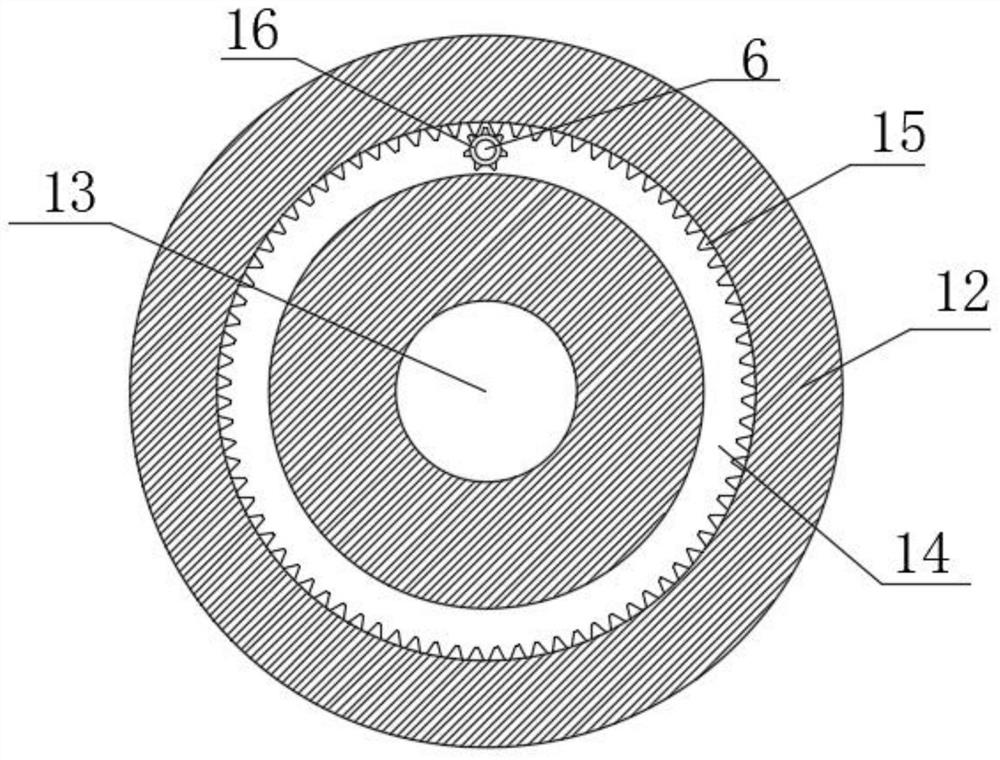

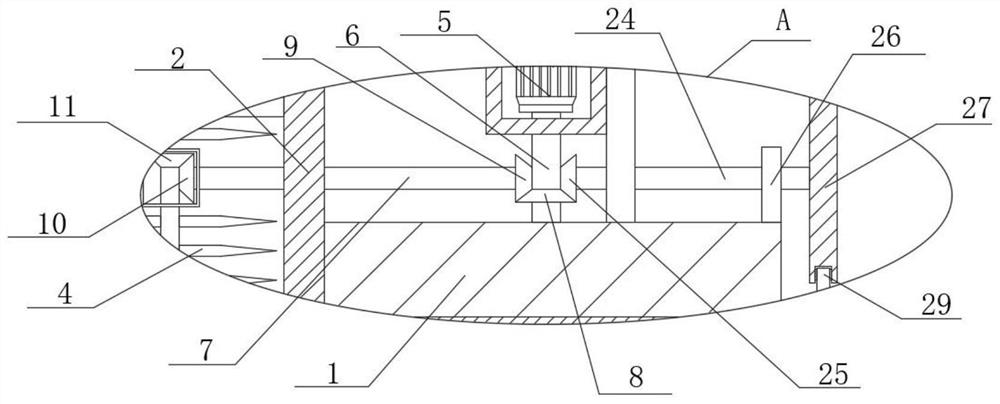

[0030] refer to Figure 1-6 , a crushing and sorting equipment for abandoned building structures, comprising a box body 1 and a mounting frame 41, a feeding pipe 2 is fixedly installed on the top of the box body 1, and a mounting rod 40 is fixedly mounted inside the feeding pipe 2, and a mounting rod 40 is mounted on the mounting rod 40. Rotating rod 3 is installed, and several crushing rods 4 are fixedly installed on the rotating rod 3, and the top of casing 1 is fixedly installed with drive motor 5, and the top of drive shaft 6 is fixedly installed on the output shaft of drive motor 5, and the drive shaft One end of the drive shaft 7 is rotated on the 6, and the other end of the drive shaft 7 is connected to the rotating rod 3. A grinding plate 12 is installed in the casing 1. A leak hole 13 is provided on the grinding plate 12. The bottom of the drive shaft 6 The end is connected with the grinding plate 12 in rotation, the installation plate 17 is fixedly installed in the b...

Embodiment 2

[0041] refer to Figure 1-7 , a crushing and sorting equipment for abandoned building structures, comprising a box body 1 and a mounting frame 41, the top of the box body 1 is fixedly installed with a feeding pipe 2 by welding, and the inside of the feeding pipe 2 is fixedly installed with a mounting rod 40 by welding, Rotating rod 3 is installed on the mounting rod 40, and several smashing rods 4 are fixedly installed on the rotating rod 3 by welding. The top of the box body 1 is fixed with a driving motor 5 by screws, and the output shaft of the driving motor 5 is fixed by welding. The top end of the drive shaft 6 is installed, and one end of the drive shaft 7 is rotated on the drive shaft 6. The other end of the drive shaft 7 is connected to the rotating rod 3 in rotation. A grinding plate 12 is installed in the casing 1, and a grinding plate 12 is set on the grinding plate 12. There is a leakage hole 13, the bottom end of the drive shaft 6 is connected to the grinding plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com