Polyurethane composite board processing system and processing technology

A processing system and composite board technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of uncontrollable foam consumption, uneven installation of upper and side boards, and influence on flatness, etc., to achieve saving Labor cost, foam filling and filling, guarantee the effect of cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

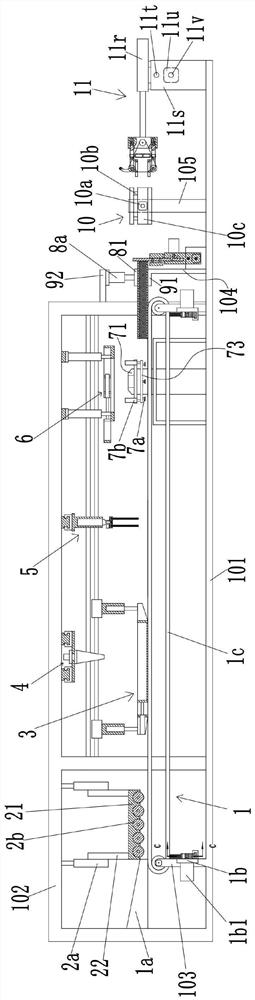

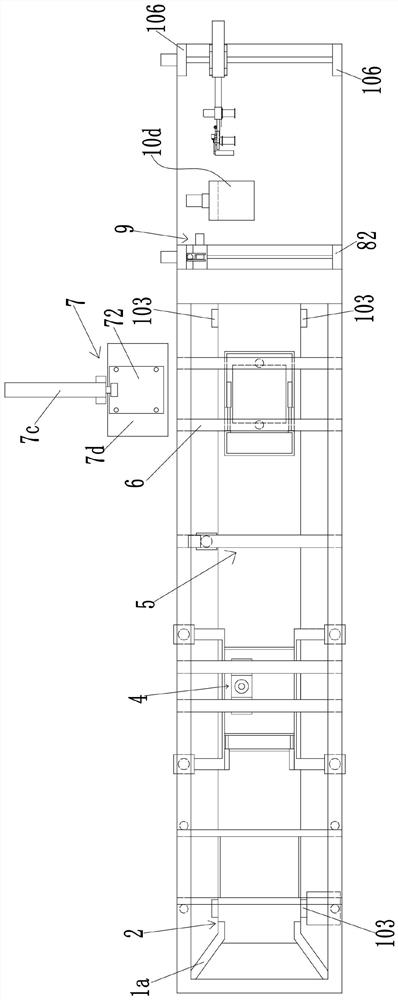

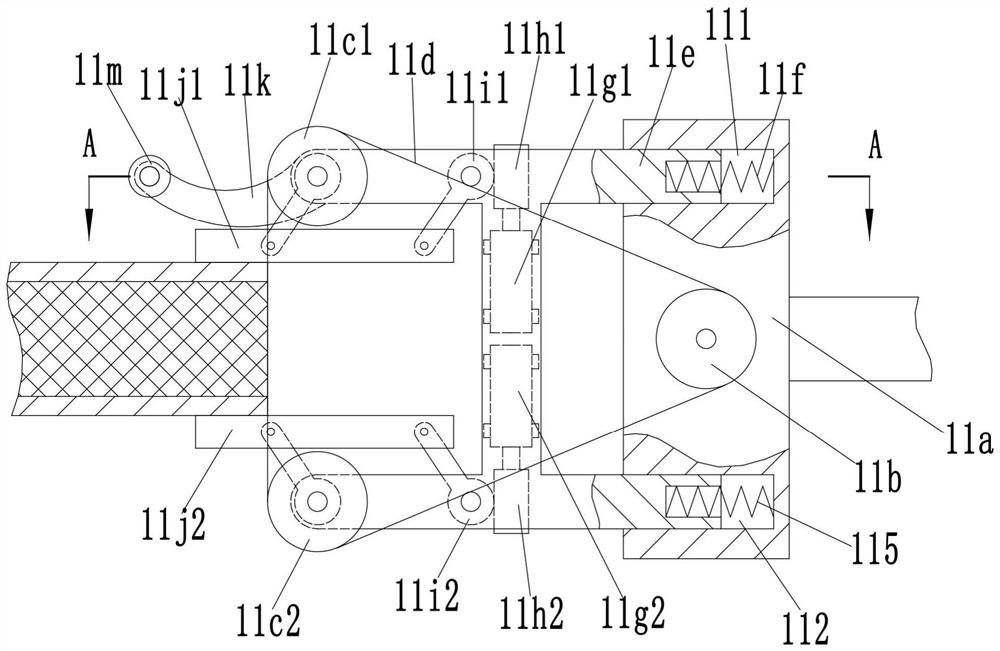

[0056] see Figure 1-15 As shown, a polyurethane composite panel processing system includes a bottom plate 101, a frame 102 is arranged on the bottom plate 101, and a transmission assembly 1 is provided in the frame 102, and the transmission assembly 1 is inside the frame 102. A mold frame assembly 3 is provided above; the frame 102 is provided with a feeding assembly 2, a filling assembly 4, a stirring and scraping assembly 5, a cover plate assembly 7, and a demoulding assembly 6 sequentially from left to right above the conveying assembly 1, The bottom plate 101 is provided with a cutting assembly 9 at the right end of the conveying assembly 1, a clamping assembly 10 is provided on the right side of the cutting assembly 9, and a grinding assembly 11 is provided at the right side of the clamping assembly 10; the feeding assembly 2 It is used to send the lower side panel to the transmission assembly 1 and make the lower side panel fit the transmission assembly 1; the mold fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com