Method for preparing barium metaphosphate by decomposing barite through ammonium dihydrogen phosphate

A technology for producing ammonium dihydrogen phosphate and barium metaphosphate, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as environmental pollution, high production cost, and affect the ecological environment, and achieves reduction of production costs and production costs. Convenience and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

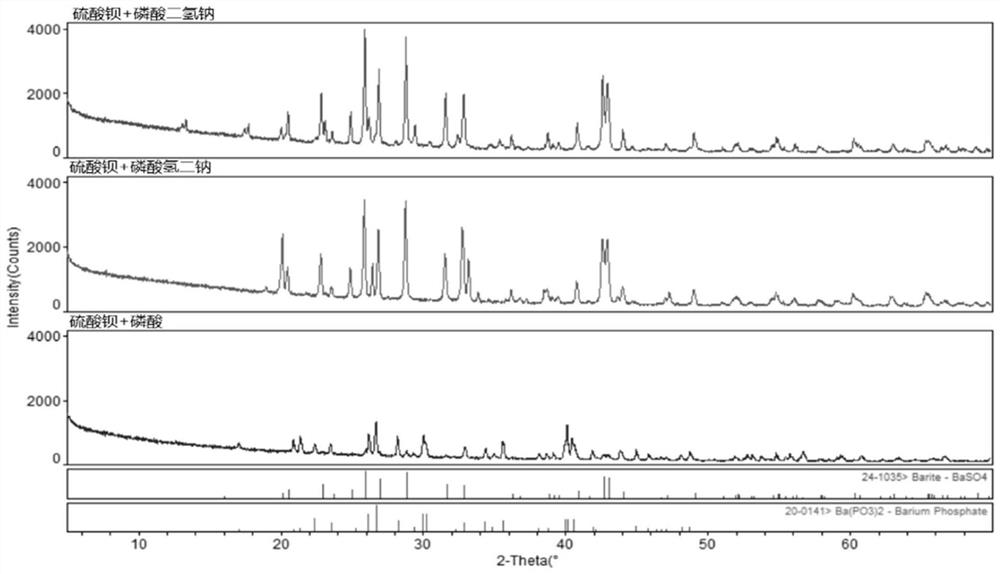

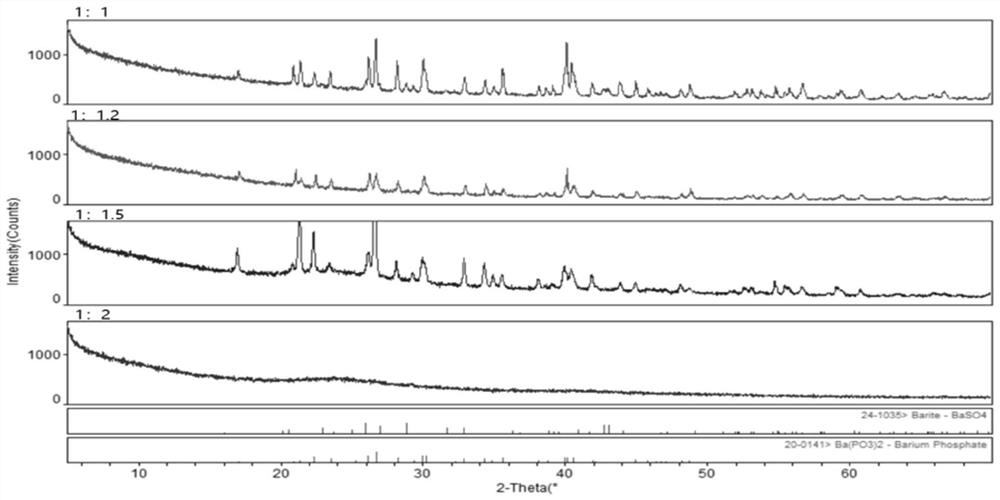

Method used

Image

Examples

Embodiment 1

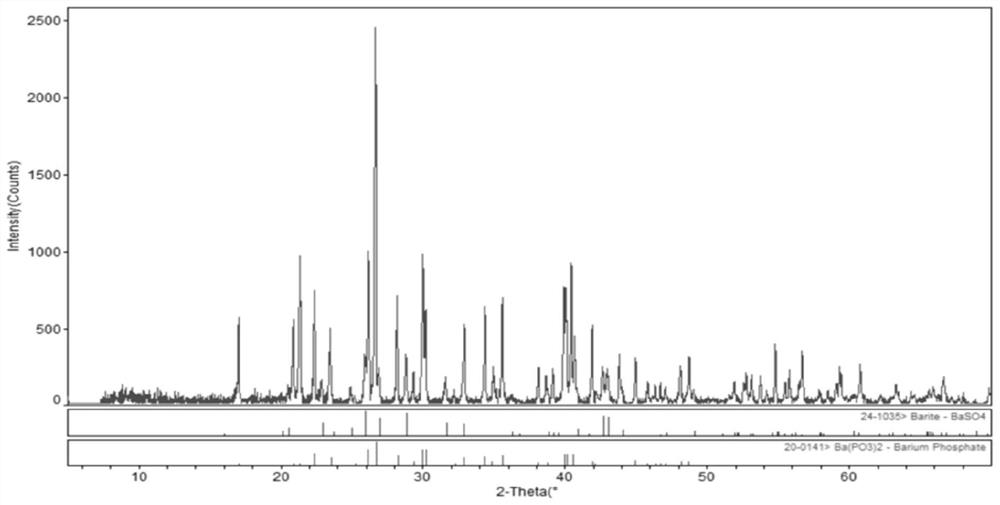

[0019] Embodiment 1: A kind of method that adopts ammonium dihydrogen phosphate to decompose barite to make barium metaphosphate, according to barite and ammonium dihydrogen phosphate mass ratio is 1: 2.0 to carry out material preparation, after two kinds of raw materials are uniformly mixed, in 500 Calcined at high temperature for 3.0h, the product obtained is barium metaphosphate.

Embodiment 2

[0020] Embodiment 2: A kind of method that adopts ammonium dihydrogen phosphate to decompose barite to make barium metaphosphate, according to barite and ammonium dihydrogen phosphate mass ratio is 1:2.0 to carry out material preparation, after two kinds of raw materials are evenly mixed, at 600 Calcined at high temperature for 2.5h, the product obtained is barium metaphosphate.

Embodiment 3

[0021] Embodiment 3: A kind of method adopting ammonium dihydrogen phosphate to decompose barite to make barium metaphosphate, according to barite and ammonium dihydrogen phosphate mass ratio is 1:2.0 to carry out material preparation, after two kinds of raw materials are evenly mixed, at 700 Calcined at high temperature for 2.5h, the product obtained is barium metaphosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com