Process for reducing ultrafiltration self-use water rate and improving recovery rate of produced water

A technology of water recovery rate and self-use water rate, which is applied in ultrafiltration, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large discharge water, difficult ultrafiltration drainage, and difficult reuse, and achieves Reduced wastewater discharge, reduced investment, and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

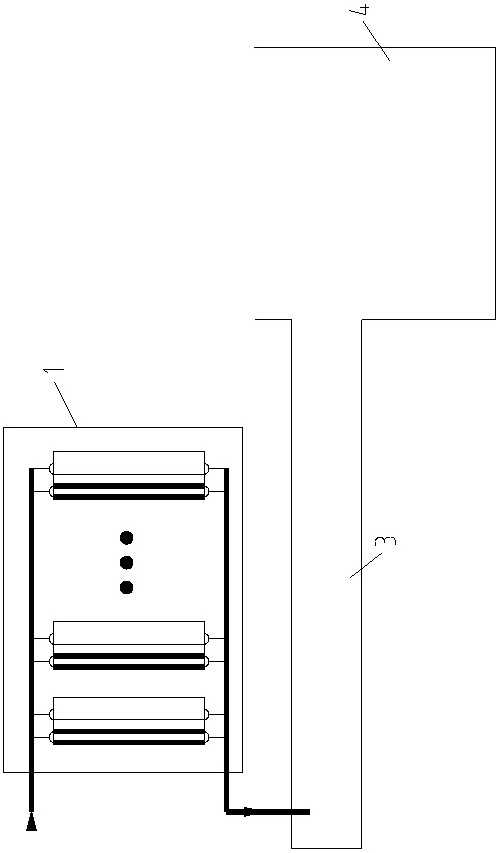

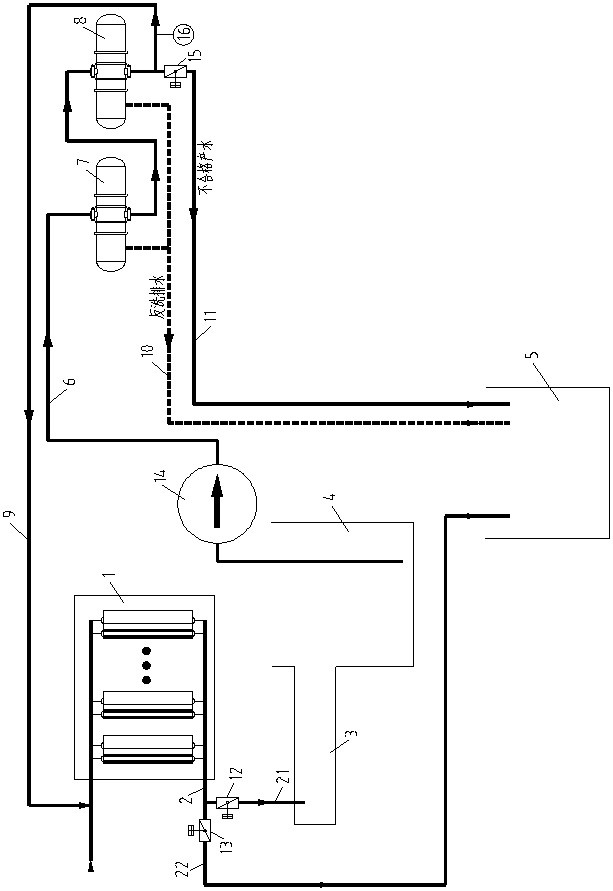

[0022] see figure 2 , in the present embodiment, a kind of technology that reduces the self-use water rate of ultrafiltration and improves the recovery rate of produced water, the process flow is as follows: the drainage of the filtration system 1 includes positive washing drainage, common backwash wastewater and enhanced backwash wastewater, and the ultrafiltration system 1 drainage It is discharged through the ultrafiltration drainage pipe 2 at the bottom. The ultrafiltration drainage pipe 2 is divided into a drainage branch 1 21 and a drainage branch 2 22. The drainage branch 1 21 is connected to the waste water pool 1 4, and the drainage branch 2 22 is connected to the waste water pool 2. 5. Install valve 1 12 and valve 2 13 on drainage branch 1 21 and drainage branch 2 22 respectively, and the positive washing drainage and ordinary backwash wastewater are discharged to waste water pool 1 4 through drainage branch 1 21 to strengthen backwash wastewater Discharge to waste ...

Embodiment 2

[0025] A thermal power plant in Hebei, with a unit capacity of 2 units of 330MW, affected by environmental protection policies, the wastewater in the plant is strictly prohibited from being discharged outside. A water balance test was carried out in 2018, and the ultrafiltration backwash wastewater was about 22m 3 / h, there is no place to consume in the factory. At the end of 2018, the ultrafiltration backwashing system was transformed by using the present invention, and the backwash wastewater was separated and recovered, reducing the ultrafiltration wastewater to 4m 3 / h, when the waste water zero-discharge transformation is implemented, the investment is saved by about 5 million yuan.

Embodiment 3

[0027] A thermal power plant in Ningxia, with a unit capacity of 2 units of 660MW, affected by environmental protection policies, the ultrafiltration backwash wastewater is about 34m 3 / h, no place to consume, in 2018, it is planned to build a zero discharge system to treat the wastewater of the whole plant, and optimize the wastewater in the plant. After the transformation of the present invention at the end of 2019, the ultrafiltration backwash wastewater was reduced to 6m 3 / h, all recycled to the wet slag removal system and ash removal system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com