Beneficiation method for multi-metal associated fluorite ore by adopting quality-divided flotation-step-by-step inhibition

A beneficiation method and fluorite ore technology, applied in flotation, chemical instruments and methods, magnetic separation, etc., can solve the problems of low flotation efficiency, insufficient flotation time, and low grade of rough concentrate in roughing operation section, Achieve the effect of avoiding irreversible damage, smooth flotation process and improving fluorite beneficiation index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

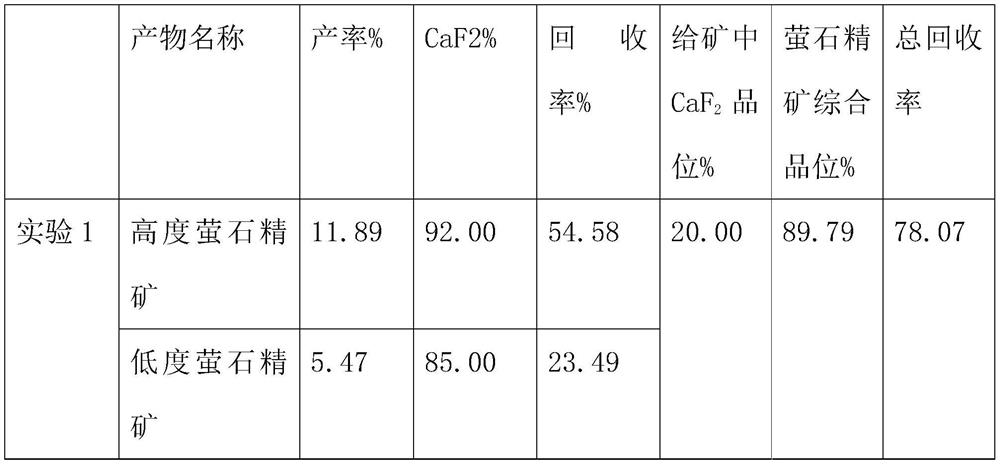

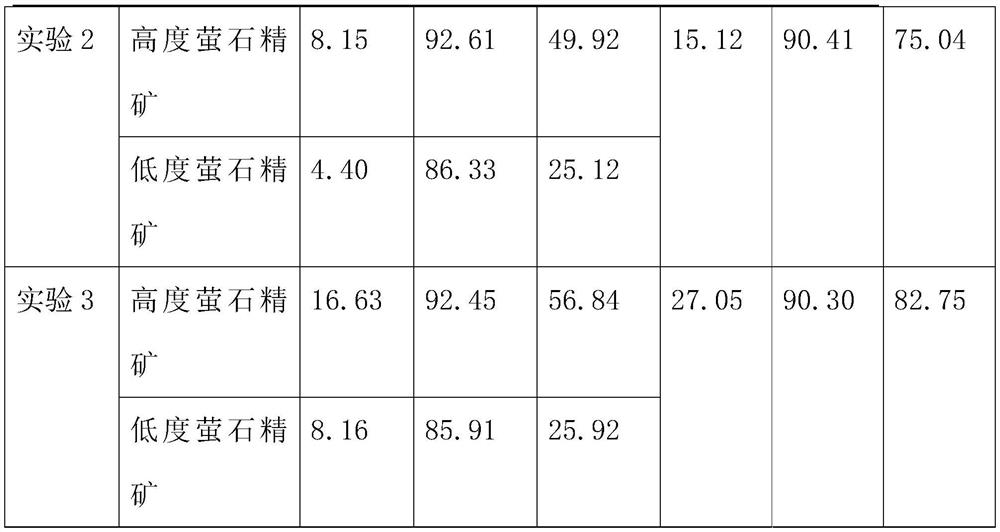

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

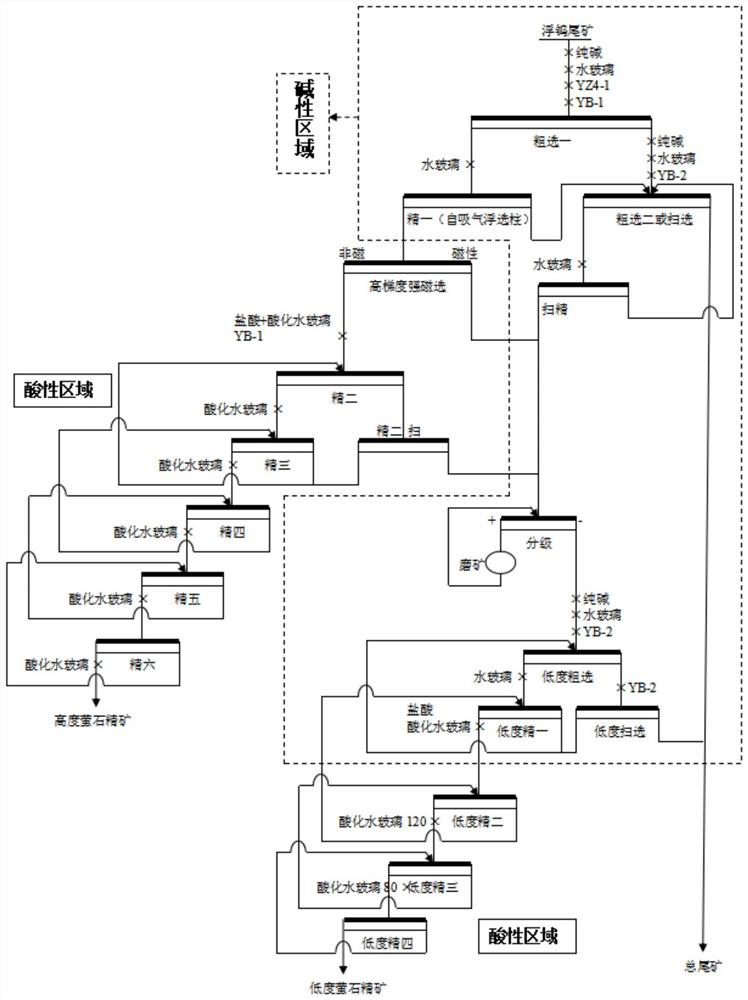

[0026] The present invention provides polymetallic associated fluorite ore using fractional flotation-step-by-step suppression ore dressing method, please refer to figure 1 , including the following steps:

[0027] S1, Fractional flotation of fluorite: the floating tungsten tailings are used as fluorite flotation ore, and the fluorite roughing operation is firstly carried out; the roughing operation mainly uses the natural buoyancy of easy-floating fluorite, and adopts relatively Carry out flotation with less reagents; the reagent system is: the dosage of sodium carbonate is 200-800g / t, preferably 500g / t, the dosage of water glass is 500-2000g / t, preferably 1250g / t, and the dosage of calcium inhibitor is 50-200g / t, preferably set to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com