Engineering plastic formula and injection molding color matching method thereof

A technology of engineering plastics and formulations, which is applied in the field of engineering plastics injection color scheme and its injection color matching, can solve the problems of complicated procedures, poor color dispersion, time-consuming and material-consuming, etc., so as to avoid the bridging effect of blanking, improve the efficiency of color matching and Accurate, well-dispersed results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

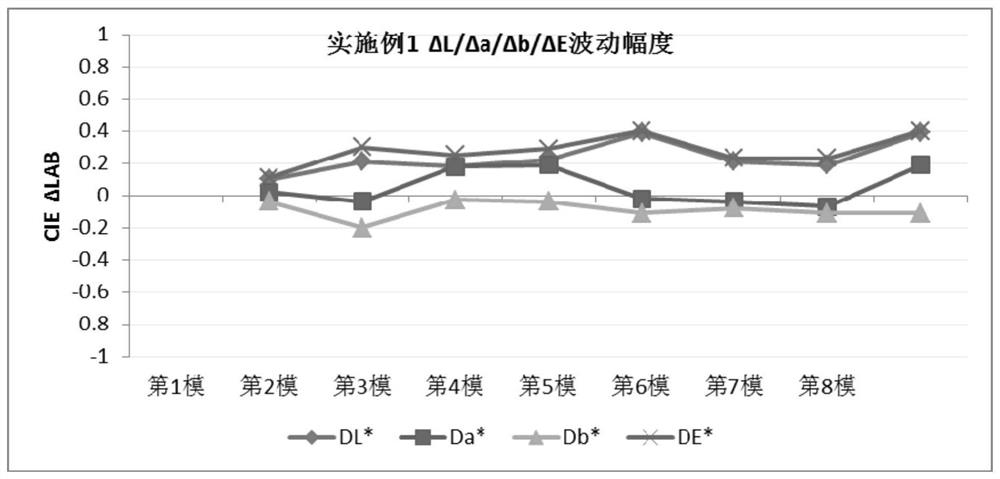

Embodiment 1

[0108]An injection molding method of engineering plastics, including the following steps:

[0109]S1. A mixture of uniformly distributed formulation components:

[0110]According to the color formation method, the components of the component materials are selected according to the actual product characteristics and target color characteristics, and the weight is greater than 20 g content component is 0.01 g of the balance, and the weight is less than 20g component. The precision is 0.001 g of the balance, and the total weight of the sample is 1000g,

[0111]The mixture of weighing material is uniformly loaded into the PE film bag with sealing strips, and the volume of the mixture in the bag is filled with air, the volume of the mixture is reasonable at 30-50%, otherwise the replacement meets this volume. The proportional PE film bag, after sealed, rock and conversion angle continuously for 30 seconds, at which time the mixture is a uniformly distributed mixture;

[0112]S2. Put the mixture of S...

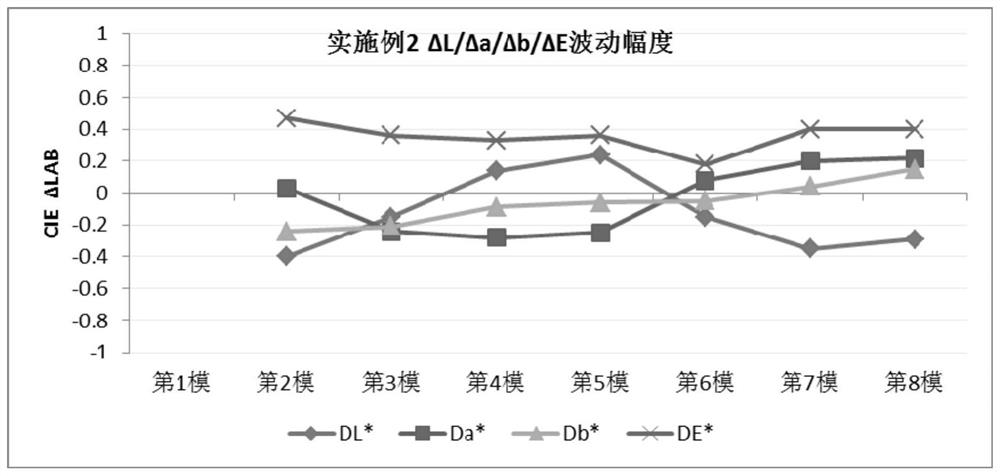

Embodiment 2

[0131]An injection molding color method of engineering plastic, specific steps, as in Example 1.

[0132]Among them, the engineering plastic formula is shown in Table 1, the specific example:

[0133]The polymer powder is 49 parts of the PC powder, and the polymer particles are 40.8 parts of PC particles, and 4 function auxiliaries are UV-234 anti-aging parental particles, 0.3 parts of the PC, and 0.3 parts. 1 #, 0.1 parts of the compatibilizer 2 #, 5 parts compatibilized pre-dispersant 4 #, 0.8 parts of the pre-dispersant 6 #.

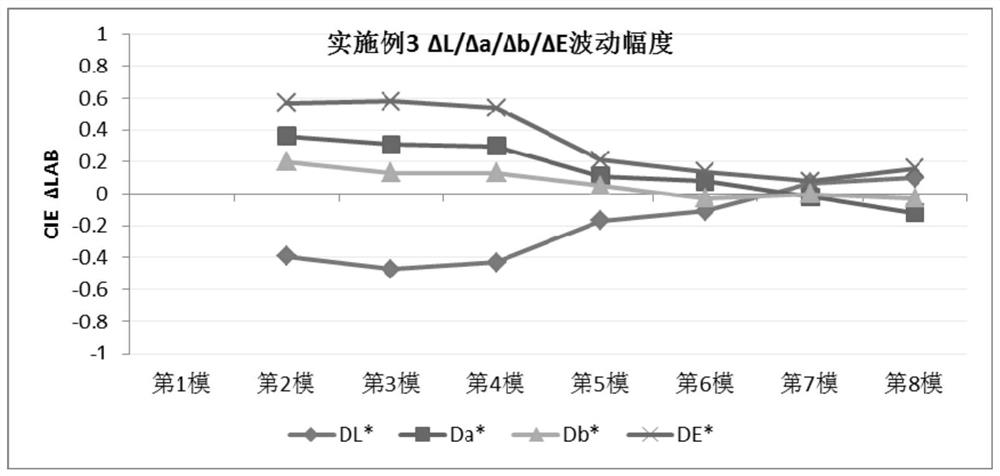

Embodiment 3

[0135]An injection molding color method of engineering plastic, specific steps, as in Example 1.

[0136]Among them, the engineering plastic formula is shown in Table 1, the specific example:

[0137]The function auxiliarion is 0.2 parts lubricant PETs, and the polymer powder is 85 parts of PBT powder, and the polymer particles are 5.27 parts of PBT particles, and the powder filler is 8 parts of talc powder, 0.13 compatibilizing pre-dispersant 1 #, 0.1 parts. Capocodynamic pre-dispersant 3 #, 1.3 parts of the pre-dispersant 5 #.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com