Medical silicone rubber and production process thereof

A production process and technology of silicone rubber, applied in the field of silicone rubber, can solve the problems of poor flexibility, difficult application, poor biocompatibility and permeability of silicone rubber, and achieve biological aging resistance, uniform vulcanization, and excellent physiological inertness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

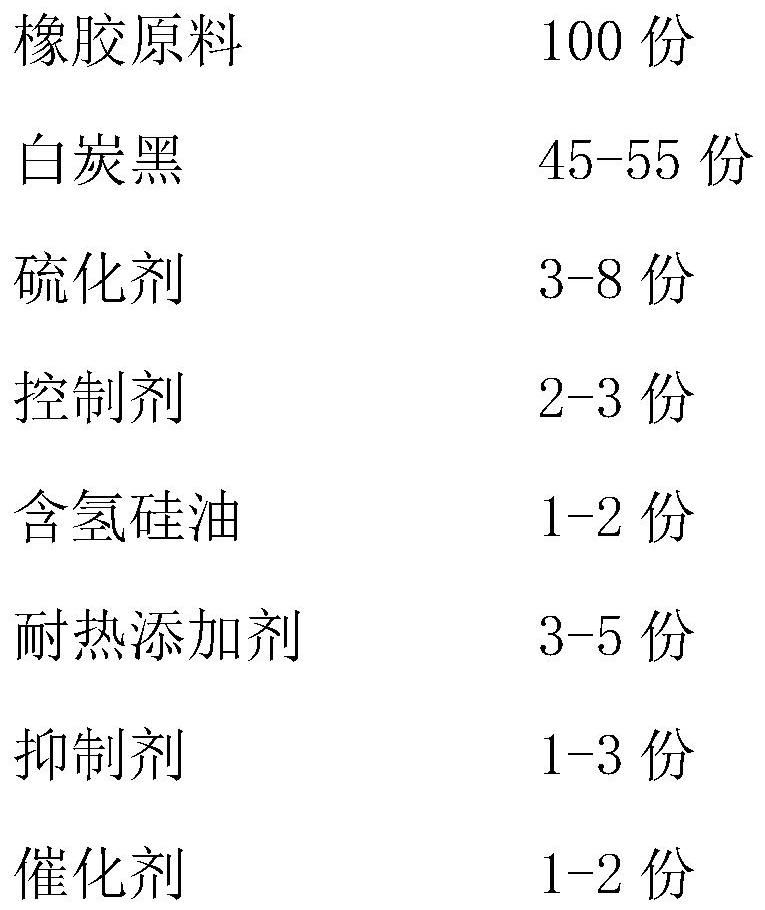

[0037] A medical silicone rubber, consisting of the following raw materials in parts by weight:

[0038]

[0039] A kind of production technology of silicone rubber for medical treatment, following steps:

[0040] S1, weighing the above raw materials by weight;

[0041] S2. Put the rubber raw material into the rubber mixing machine for mastication, add one-half of the white carbon black after the rubber roll, adjust the width of the roller, turn over the rubber material, mix and finally beat it into a film with a thickness of 5-8mm. Put it into the electric heating drying box for heat treatment, take it out and age it in the dryer, add vulcanizing agent to the aged rubber material on the open mill, let the curing agent evenly eat into the rubber material, and punch it out of the machine;

[0042] S3, add the refined silicone rubber to the rubber mixing machine to cover the roll again, add the control agent and the remaining 1 / 2 of the white carbon black, thin pass 5 times,...

Embodiment 2

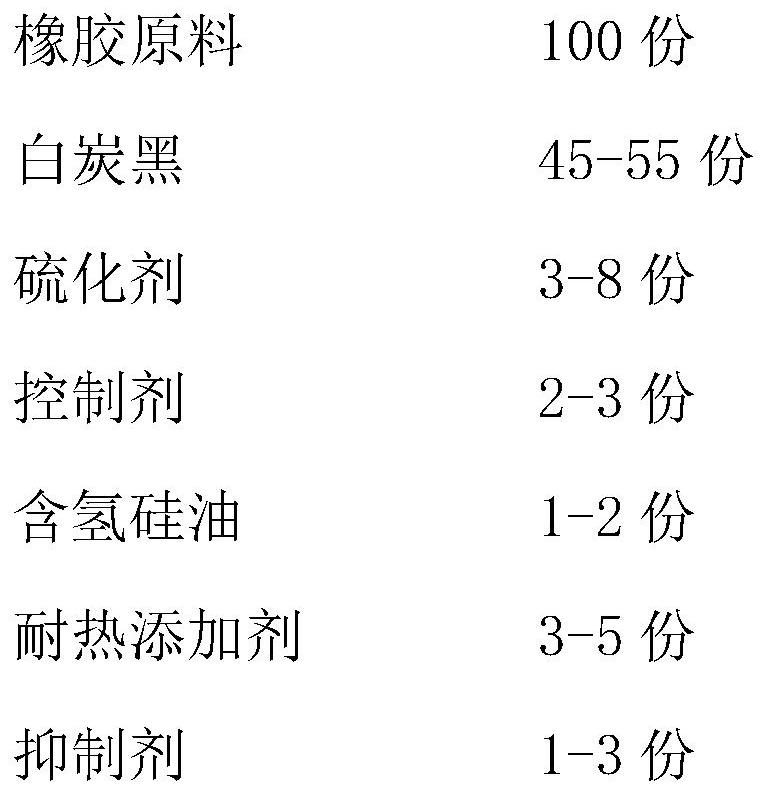

[0045] A medical silicone rubber, consisting of the following raw materials in parts by weight:

[0046]

[0047] A kind of production technology of silicone rubber for medical treatment, following steps:

[0048] S1, weighing the above raw materials by weight;

[0049] S2. Put the rubber raw material into the rubber mixing machine for mastication, add one-half of the white carbon black after the rubber roll, adjust the width of the roller, turn over the rubber material, mix and finally beat it into a film with a thickness of 5-8mm. Put it into the electric heating drying box for heat treatment, take it out and age it in the dryer, add vulcanizing agent to the aged rubber material on the open mill, let the curing agent evenly eat into the rubber material, and punch it out of the machine;

[0050] S3, add the refined silicone rubber to the rubber mixing machine to cover the roll again, add the control agent and the remaining 1 / 2 of the white carbon black, thin pass 5 times,...

Embodiment 3

[0053] A medical silicone rubber, consisting of the following raw materials in parts by weight:

[0054]

[0055]

[0056] A kind of production technology of silicone rubber for medical treatment, following steps:

[0057] S1, weighing the above raw materials by weight;

[0058] S2. Put the rubber raw material into the rubber mixing machine for mastication, add one-half of the white carbon black after the rubber roll, adjust the width of the roller, turn over the rubber material, mix and finally beat it into a film with a thickness of 5-8mm. Put it into the electric heating drying box for heat treatment, take it out and age it in the dryer, add vulcanizing agent to the aged rubber material on the open mill, let the curing agent evenly eat into the rubber material, and punch it out of the machine;

[0059] S3, add the refined silicone rubber to the rubber mixing machine to cover the roll again, add the control agent and the remaining 1 / 2 of the white carbon black, thin pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com