Cement kiln flue gas NOx ultra-low emission method and system

A discharge system, cement kiln technology, applied in the direction of separation methods, chemical instruments and methods, furnaces, etc., can solve problems such as inability to respond well, achieve stable and reliable discharge concentration, reduce ammonia discharge concentration, and reduce the formation of NOx.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

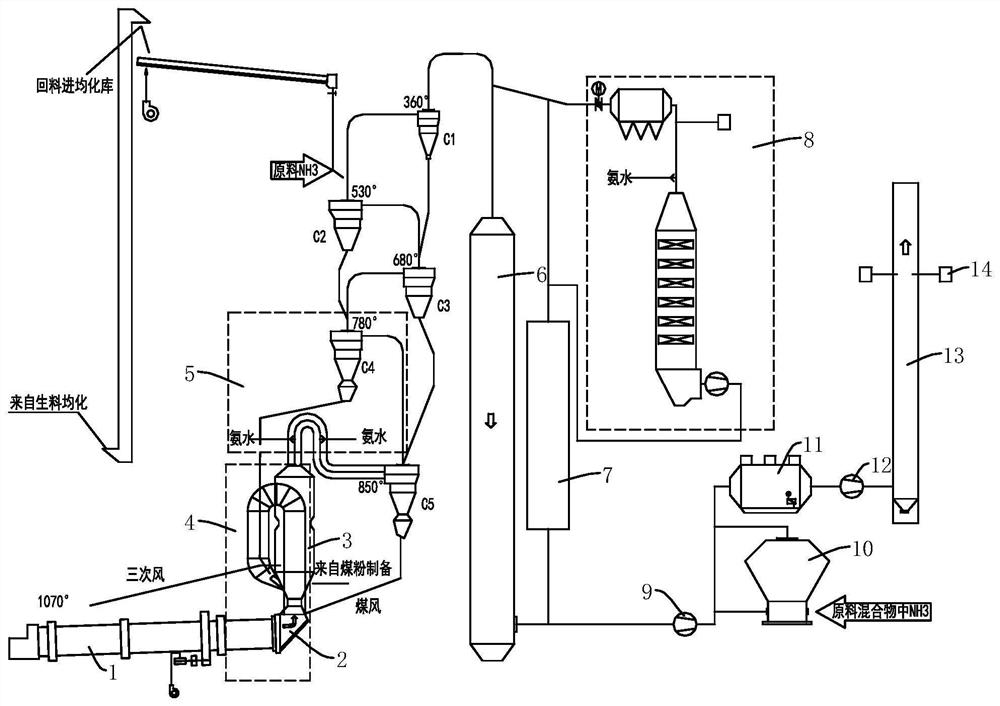

[0091] On the 5000t / d clinker line according to figure 1 The transformation shown is carried out, the main design parameters are: the air volume is 520000Nm 3 / h, the initial concentration of NOx before transformation is 650-800mg / m 3 , NOx outlet concentration 3 , ammonia emission concentration 3 .

[0092] Before the transformation, the flue gas volume was 520000~560000Nm 3 / h, NOx emission concentration 680-750mg / m 3 , after the traditional SNCR denitrification transformation has been implemented, the NOx emission concentration is 320-400mg / m 3 .

[0093] according to figure 1 After the transformation is completed, the debugging situation is as follows:

[0094] Working condition 1: Only high-efficiency and low-nitrogen combustion technology is used (that is, the ammonia injection of the SNCR denitrification system is stopped, and the flue gas baffle door at the entrance of the SCR reactor is closed), and the measured NOx emission concentration of the kiln tail chimne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com