High-temperature molten salt furnace with two stages of combustors

A high-temperature molten salt, high-level combustion technology, applied in the direction of furnace, charge, crucible furnace, etc., can solve the problem of low temperature of molten salt, achieve the effect of avoiding local high temperature and reducing the production of nitrogen oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments, and the purpose and effect of the present invention will become clearer. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to limit the present invention.

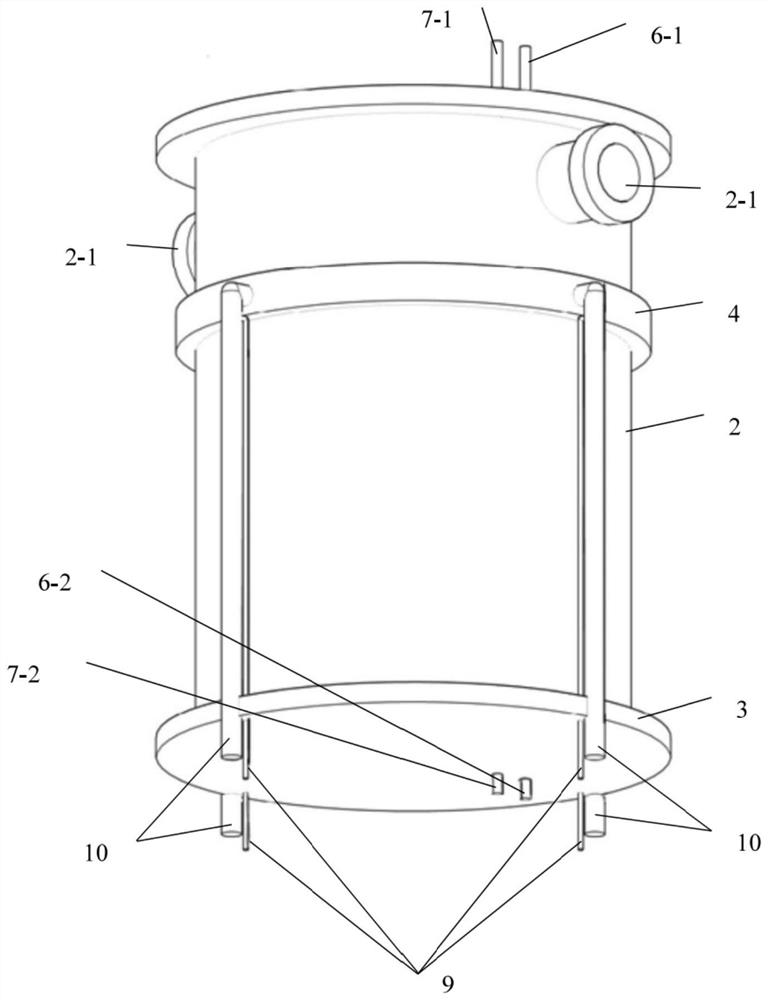

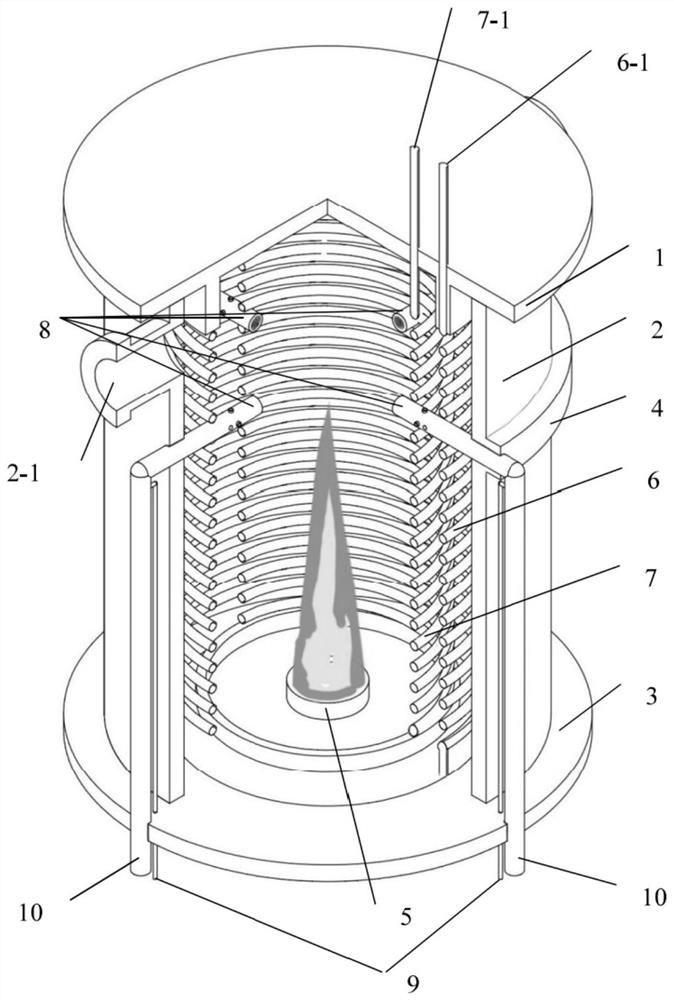

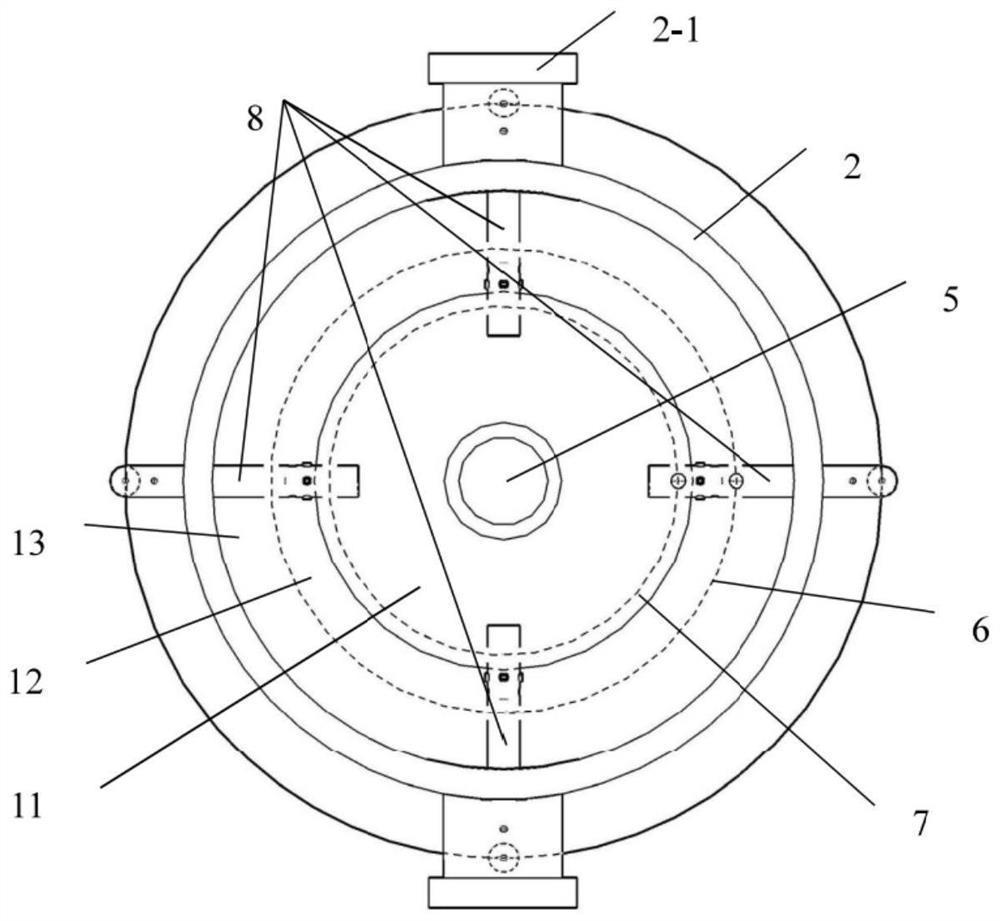

[0032] like figure 1 and 2 As shown, the high-temperature molten salt furnace with two-stage burners of the present invention includes a top cover 1, a furnace body 2, a base 3, a secondary burner bracket 4, an outer coil 6, an inner coil 7, and a primary burner 5. Secondary burner 8, fuel supply pipe 9 and air distribution pipe 10.

[0033] Wherein, from top to bottom, the top cover 1, the furnace body 2, and the base 3 are fixedly connected in sequence, and the interior of the three forms a combustion space. The furnace body 2 is also symmetrically provided with flue gas outlets 2-1. The secondary bur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com