Image alignment adjustment and inspection method applied to low-light-level image intensifier

A low-light image intensifier and inspection method technology, which is applied in the field of image alignment adjustment and inspection, can solve the problems of undetectable, uncontrollable coaxiality between the cathode input center of the low-light image intensifier and the center of the shell, etc., to achieve easy The operation and reading are simple and intuitive, and the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]The present invention will be further described in detail below with reference to the accompanying drawings and examples, but the scope of the invention is not limited to the content.

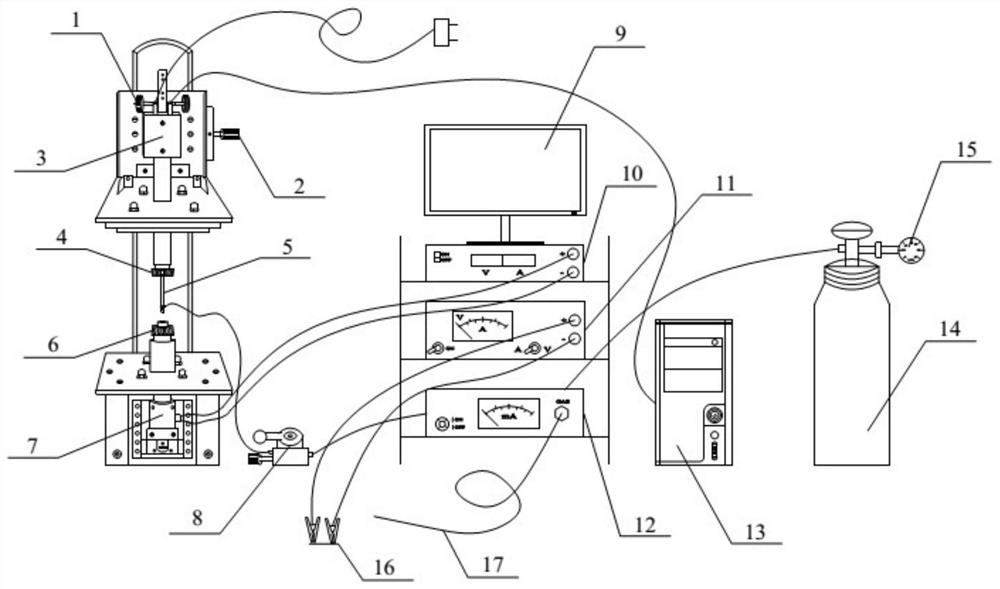

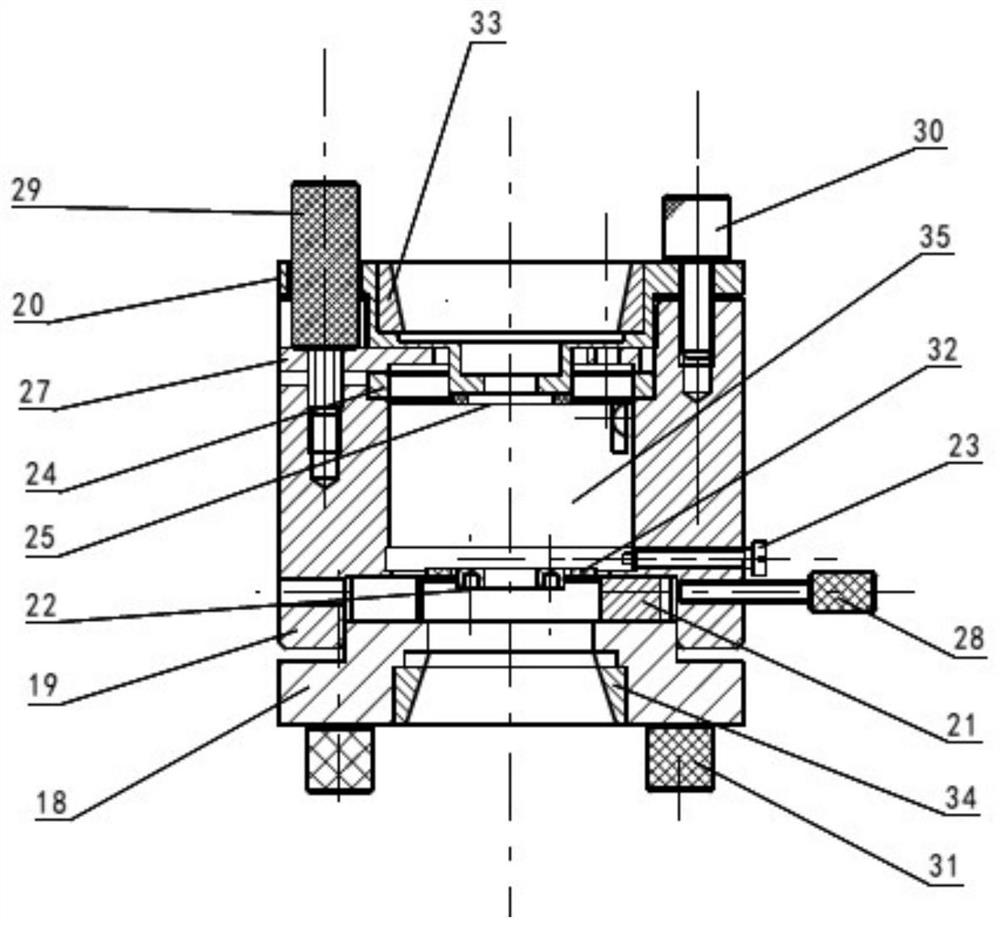

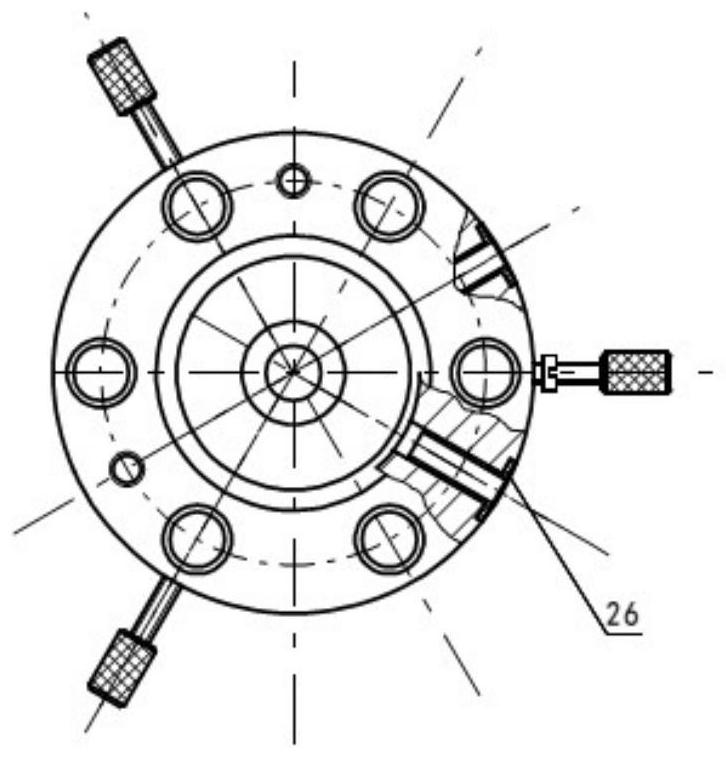

[0045]An image-aligned adjustment and inspection system applied to a micro-light image reinforcerator, including: CCD camera 3, light source 7, gas control machine 12, valve 8, and regulator power supply 11. The CCD camera 3 is connected to the computer 13, and the crossline of the potting mold or the inspection mold can be observed in real time by computer 13 for calibration or testing. The light source 7 provides a light source for a micro-image enhancer on a potting mold or a test mold for a CCD camera 3. The gas control machine 12 is connected to the valve 8 to provide pneumatic power of the pneumatic shaft 5 through the valve 8. The regulator power source 11 is a gas controller 12 powered by the required power.

[0046]The system also includes a potting mold that is equipped with an unmovable mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com