Liquid hydrocarbon transfer system and assembly

A technology of pump components and components, applied in the direction of charging system, pump components, engine components, etc., can solve problems such as pump operation obstruction or stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

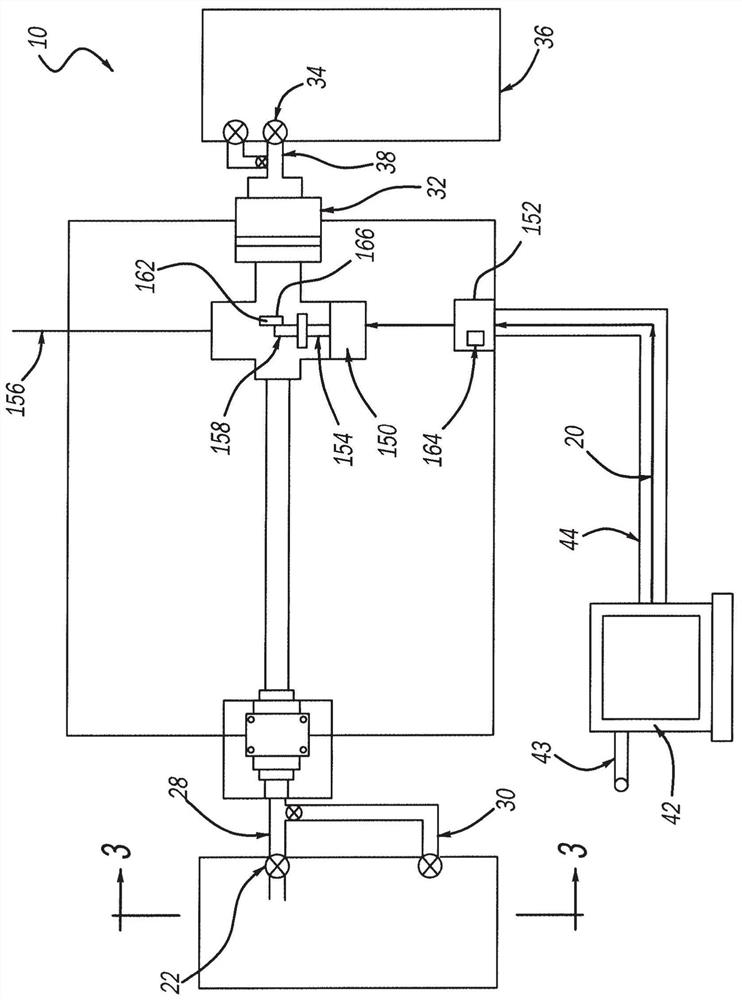

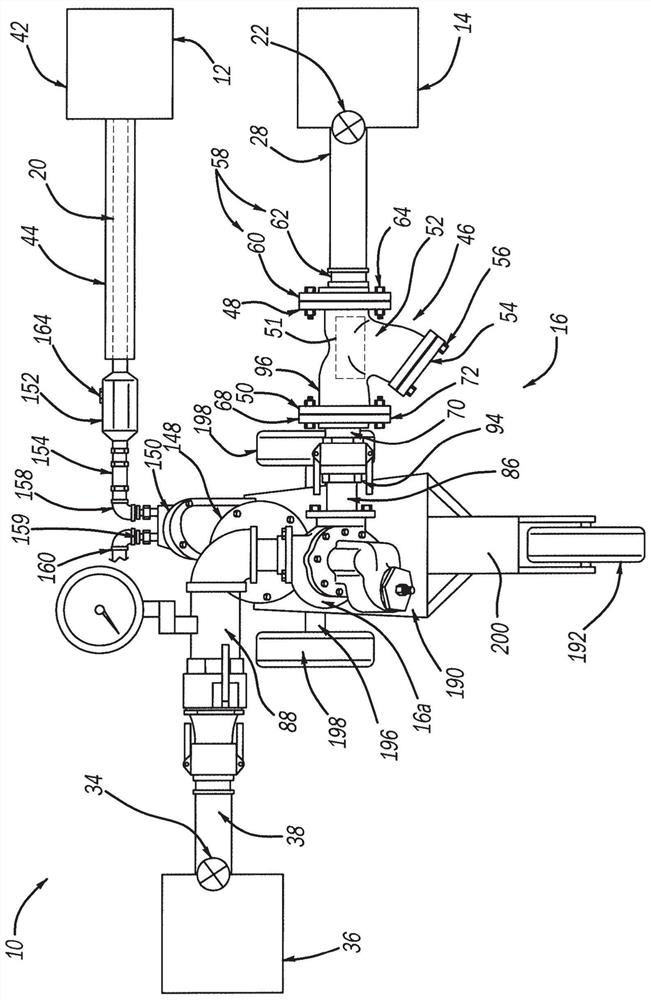

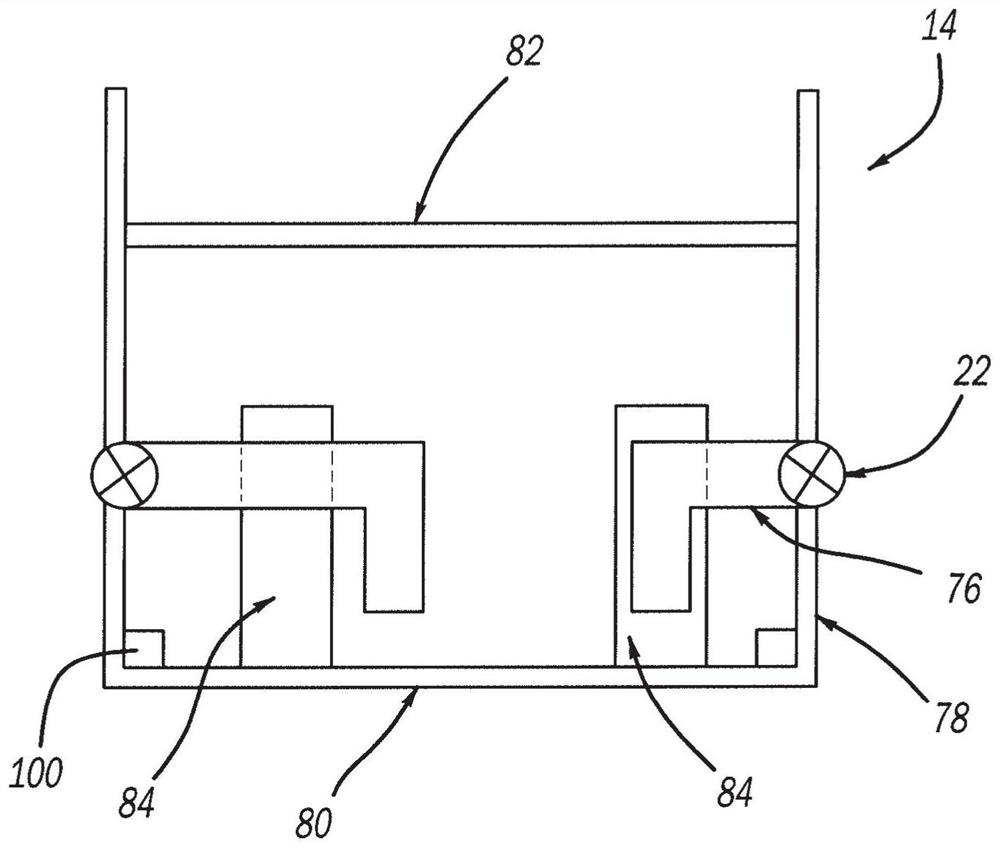

[0019] According to the present invention, the liquid hydrocarbon transfer facility 10 includes an air compressor 12 at a location preferably spaced from the storage tank 14 (i.e., outside the berm containing the storage tank 14), wherein the storage tank 14 is Tank 14 contains bulk fluid such as, for example, hydrocarbon fuel. Liquid hydrocarbon transfer pump assembly 16 is positioned proximate to storage tank 14 , preferably somewhere within the berm containing storage tank 14 . The hydrocarbon transfer pump assembly 16 is operatively connected to the air compressor 12 by an elongated air supply hose 20 . The air compressor 12 is preferably located outside of the berm housing the storage tank. The fuel transfer pump assembly 16 is connected to a first outlet valve 22 on the storage tank 14 by a main flexible hydrocarbon discharge line 28 .

[0020] The hydrocarbon transfer pump assembly 16 may also be connected to the second outlet valve 24 by an auxiliary flexible hydroca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com