System control method for roundness of cigarette blast beads

A technology of popping beads and roundness, which is applied in the field of tobacco processing, and can solve the problems of low pass rate of roundness value of cigarette popping beads, affecting the feeling of pinching and popping, and prone to popping beads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Use carrageenan, gelatin and other animal and plant gums as rubber raw materials, adjust the formula composition to obtain the glue viscosity suitable for popping beads, and the gel speed is appropriate.

[0028] At 75°C, gelatinization was carried out for 30 minutes.

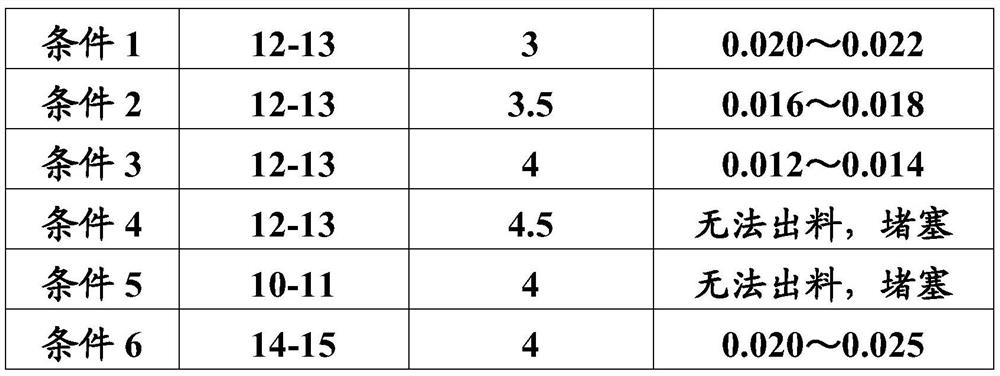

[0029] Use a drop pill machine for dripping. The dripping speed / temperature of the dripper during the dripping process of the wet explosion matches the flow rate / temperature of the cooling oil to avoid out-of-roundness during the dripping process. Specifically, the dripping conditions of wet explosion beads: glue pump 100-150 turns / min, core material pump 40-80 turns / min; cooling conditions: return pump speed 8HZ, cooling liquid discharge pipeline penetration 4 meters (the pipeline is more Longer, the longer the cooling time), the coolant temperature is 12-13°C.

[0030] Roundness test method: adopt the cigarette capsule quality monitoring system produced by Chengdu Ruituo Company, the popping beads ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com