Method for increasing regeneration speed of desulfurization liquid in regeneration tower

A technology of regeneration speed and desulfurization liquid, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of difficult heating of desulfurization liquid, difficulty in regeneration, affecting the progress of system debugging, etc. Consumption, the effect of reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

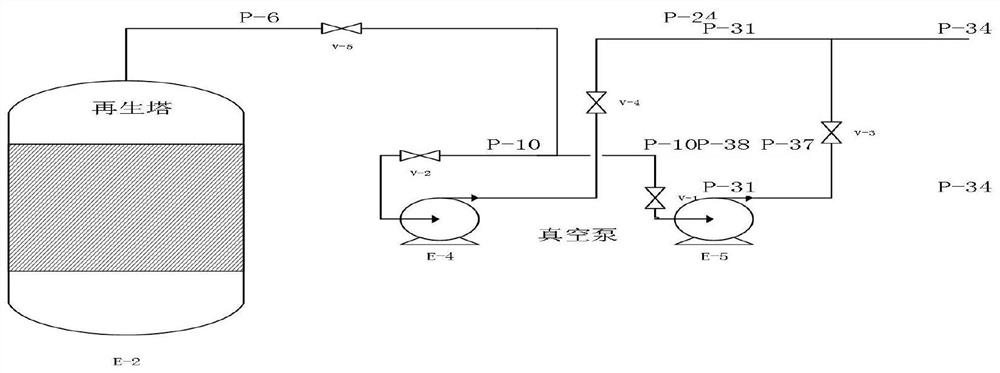

[0015] A method for increasing the regeneration speed of the desulfurization liquid in the regeneration tower, such as figure 1 As shown, two vacuum pumps are installed in the rear system of the regeneration tower, one for operation and one for standby. When the system is running, one vacuum pump is started to reduce the surface pressure of the desulfurization liquid in the regeneration tower from 50KPa to -60KPa, and the boiling point of the desulfurization liquid is about 120°C The temperature is lowered to about 95°C, the amount of steam is reduced from 12t / h to 8t / h, and the heating time at start-up is reduced from 12-16 hours to less than 8 hours, thus solving the problem of difficult stripping of desulfurization liquid in desulfurization towers in the past.

[0016] In the present invention, two vacuum pumps are added to the system at the rear of the regeneration tower, one for operation and the other for standby. When the system is running, one vacuum pump is started to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com