Nondestructive cutting spray head device for solar cells

A technology of solar cells and cells, which is applied in the direction of welding/welding/cutting items, circuits, laser welding equipment, etc., can solve the problem of non-destructive cutting, reducing the mechanical properties of cells, bending strength, power loss of small cells, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

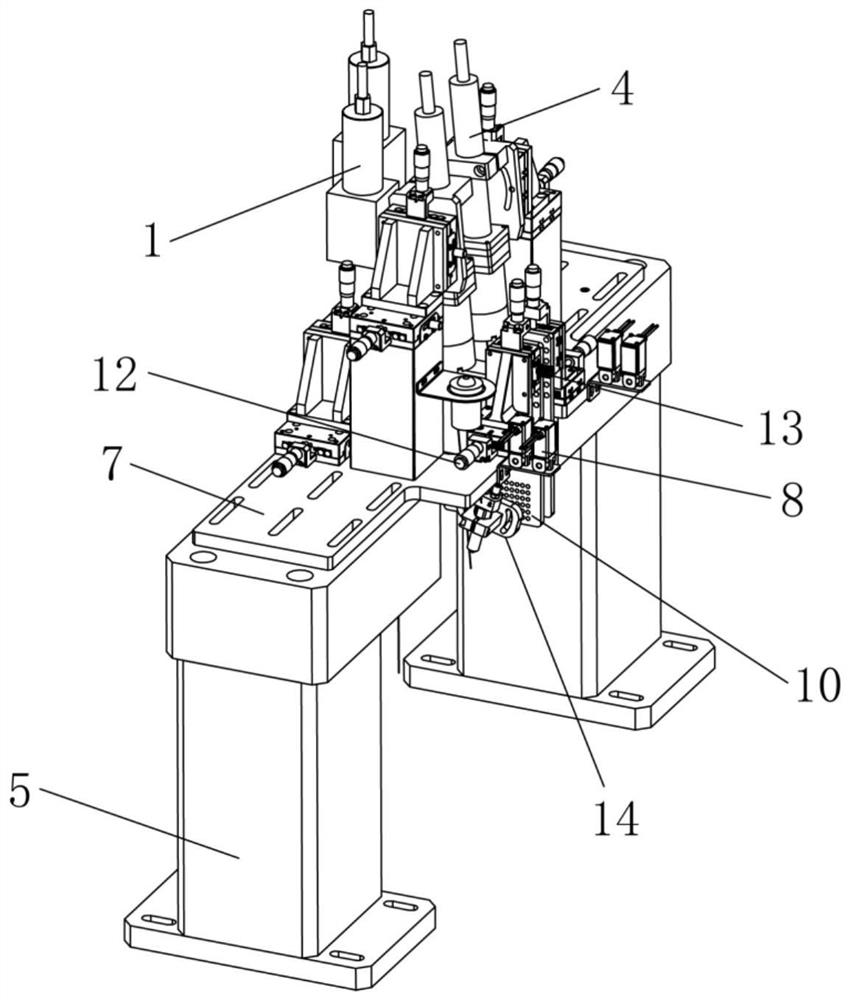

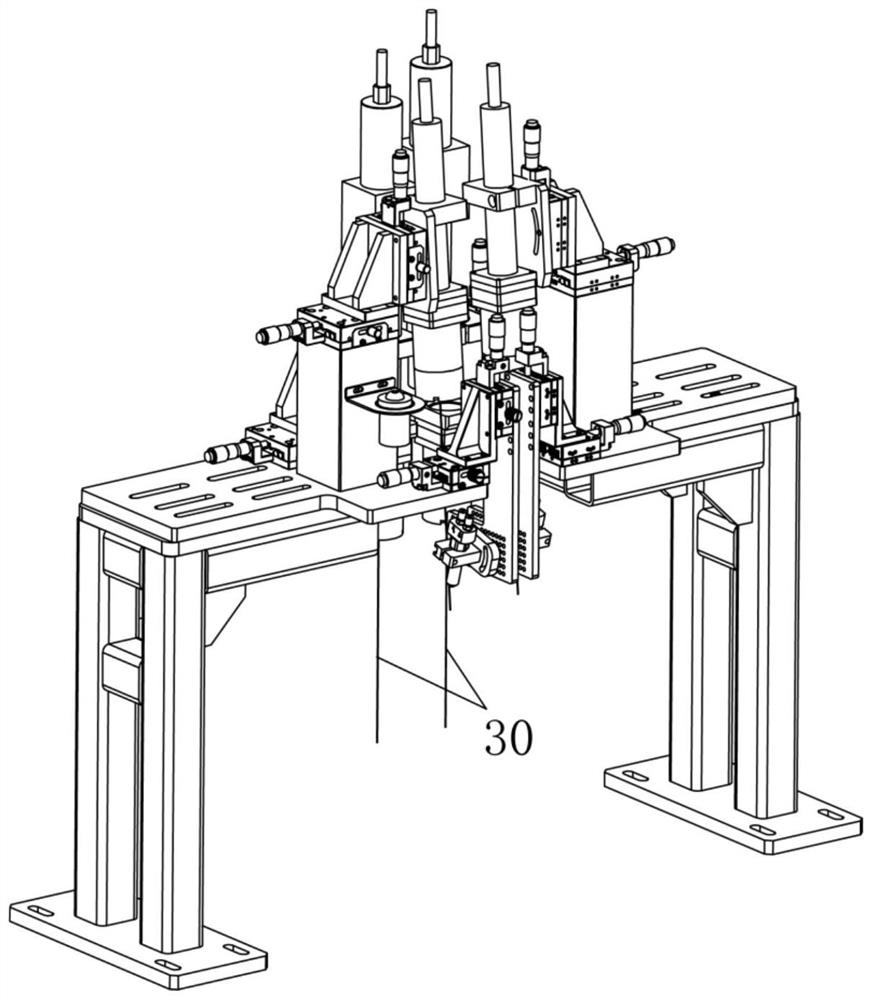

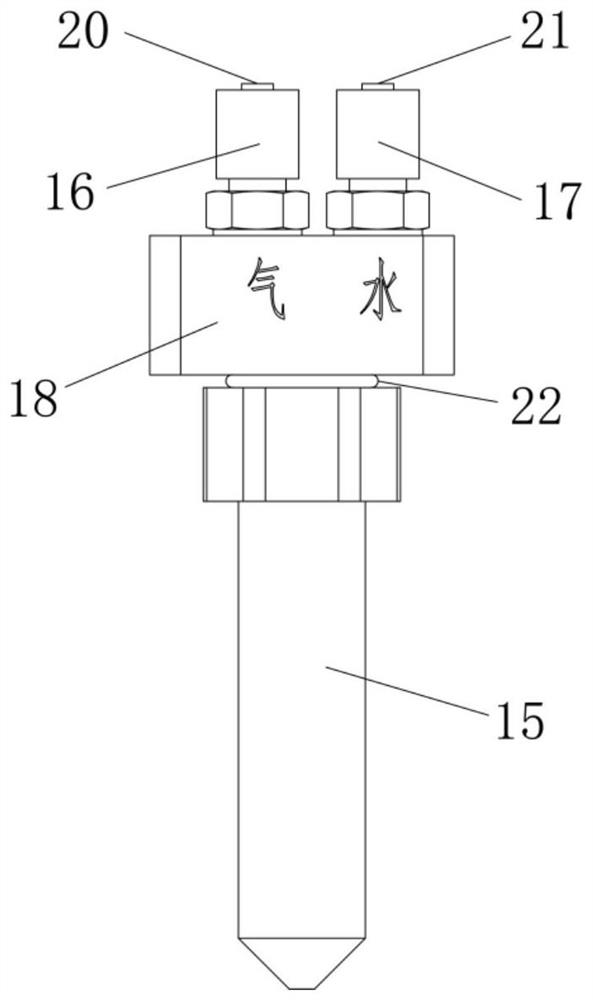

[0025] like Figure 1 to Figure 4 As shown, a non-destructive cutting nozzle device for solar cells according to the present invention includes a machine platform 7 on which a laser 30 for cutting cells and a nozzle assembly 10 for cooling cells are provided. The nozzle assembly 10 includes Nozzle 15, air inlet pipe 16 and water inlet pipe 17, air inlet pipe 16 and water inlet pipe 17 are connected to nozzle 15 through air-water joint 18, nozzle 19 is provided in nozzle 15, nozzle 19 and laser 30 corresponding settings, air inlet pipe 16 is provided with The air inlet 20 is connected to the nozzle 19 through the air inlet passage, and the water inlet 21 is arranged on the water inlet pipe 17, and the water inlet 21 is connected to the nozzle 19 through the water inlet passage. The above constitutes the basic structure of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com