A low-temperature sintered microwave dielectric material mg 2-x co x v 2 o 7 and its preparation method

A mg2-xcoxv2o7, microwave dielectric material technology, applied in sustainable manufacturing/processing, climate sustainability, chemical industry and other directions, can solve the problems of high sintering temperature, microwave dielectric properties need to be improved, etc. Solve the effect of high sintering temperature and low production cost

Active Publication Date: 2022-05-31

UNIV OF ELECTRONICS SCI & TECH OF CHINA

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

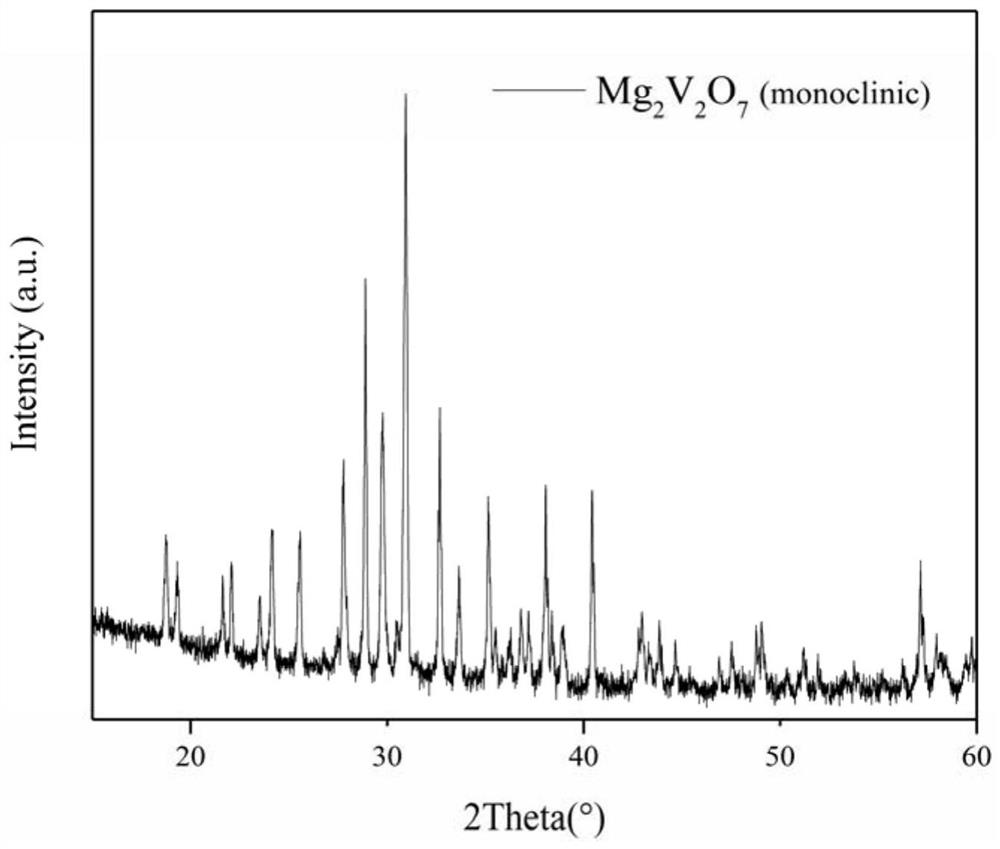

In this paper, the solid-state reaction method was used to prepare Mg 2 V 2 o 7 Microwave dielectric ceramics whose microwave dielectric properties are ε r =10.5, Q×f=58275GHz, τ f =-26.9ppm / ℃, the sintering temperature is still high, and the microwave dielectric properties need to be improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

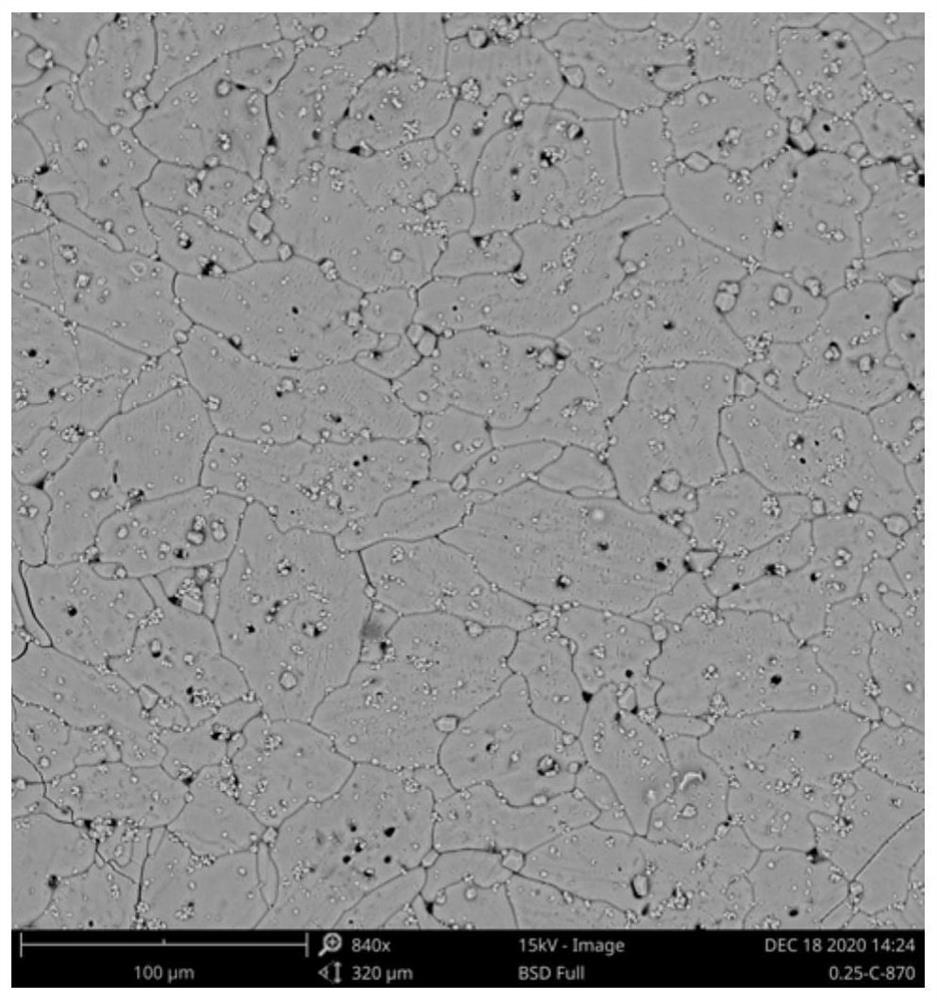

[0028] Step 6: sintering the green body at a temperature of 860-870° C. for 5-6 hours to obtain the microwave ceramic material.

[0030]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

Login to View More

Abstract

The invention belongs to the field of electronic ceramics and its manufacture, and provides a low-temperature sintered microwave dielectric material and a preparation method thereof; the low-temperature sintered microwave dielectric material is: Mg 2‑x co x V 2 o 7 (0.5≤x≤1.0), its crystal phase is: Mg 2 V 2 o 7 , the crystal structure is: monoclinic crystal structure, cobalt ions and magnesium ions occupy the A site together. In the present invention, the addition of cobalt ion makes the crystal phase Mg of microwave medium 2 V 2 o 7 From the triclinic structure to the monoclinic structure, the grain grows and the atomic packing rate increases, which greatly improves the Q×f value; at the same time, the low temperature sintering at 860-870°C is realized, which solves the problem of microwave dielectric materials The problem of high sintering temperature. The invention provides a low-temperature sintered microwave dielectric material with excellent microwave dielectric properties at a sintering temperature of 860-870°C: a dielectric constant of 8-9, a Q×f value of 66000-72000 GHz, and a resonant frequency temperature coefficient of -30-- 26ppm / °C; moreover, the low-temperature sintered microwave dielectric material has a simple preparation process and low production cost, which is conducive to realizing industrial production.

Description

A low temperature sintered microwave dielectric material Mg 2‑x Co x V 2 O 7 and preparation method thereof technical field The invention belongs to the field of electronic ceramics and manufacture thereof, relate to microwave dielectric ceramics Mg 2 V 2 O 7 doping modification, specific A kind of low temperature sintering microwave dielectric material Mg 2‑x Co x V 2 O 7 and its preparation method. Background technique Low temperature co-fired ceramic (LTCC) technology has been widely used in the field of microwave device preparation, such as mobile phones, satellite Radio, radar, etc. Practical microwave dielectric materials need to have low dielectric loss, appropriate dielectric constant and near zero harmonics. temperature coefficient of vibration frequency. MgO‑V 2 O 5 Vanadates are widely used for their inherent low sintering temperature and excellent microwave performance. Note, Joung et al published an a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B35/495C04B35/622C04B35/64

CPCC04B35/495C04B35/622C04B35/64C04B2235/3206C04B2235/3239C04B2235/3275Y02P20/10

Inventor 李波曹慧敏韩如意

Owner UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com