Method for preparing cell wall polysaccharide by utilizing ganoderma lucidum spore powder raffinate and product and application thereof

A technology of Ganoderma lucidum spore powder and broken Ganoderma lucidum spore powder, which is applied in the field of preparing cell wall polysaccharides from the extract residue of Ganoderma lucidum spore powder, can solve the problems of polysaccharide raw material waste, etc., and achieve the goal of improving utilization rate, improving economic benefits, and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

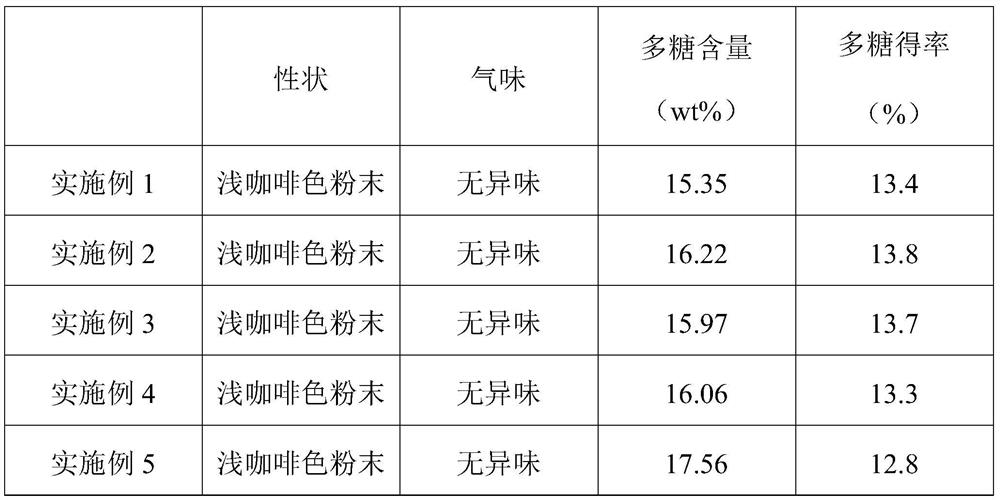

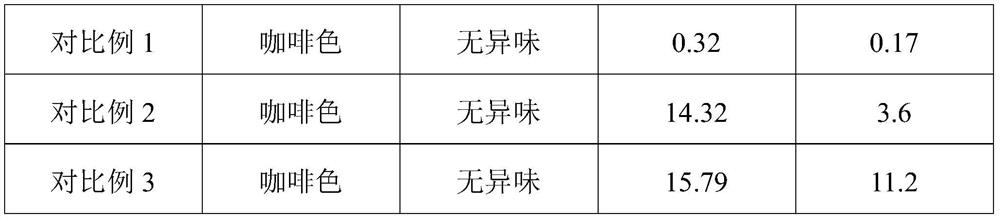

Examples

Embodiment 1

[0055] This embodiment provides a method for preparing cell wall polysaccharides from Ganoderma lucidum spore powder raffinate, said method comprising the following steps:

[0056] (1) In the BFM100B ultrafine powder vibrating mill, the extract residue of Ganoderma lucidum spore powder was subjected to wall-breaking treatment at -5°C, and the time of wall-breaking treatment was 20 minutes to obtain the extract residue of broken wall Ganoderma lucidum spore powder;

[0057] (2) Use ultra-pure water to carry out extraction treatment to step (1) obtained broken ganoderma lucidum spore powder raffinate under stirring condition at 90 ℃, the liquid-to-material ratio of extraction treatment is 20:1, and the time of extraction treatment is After 200min, the extract was obtained after solid-liquid separation;

[0058] (3) The extract obtained in step (2) was allowed to stand at 20° C. for 10 h, and then subjected to solid-liquid separation to obtain a supernatant;

[0059] (4) carry o...

Embodiment 2

[0062] This embodiment provides a method for preparing cell wall polysaccharides from Ganoderma lucidum spore powder raffinate, said method comprising the following steps:

[0063] (1) In the BFM100B ultrafine powder vibrating mill, the extract residue of Ganoderma lucidum spore powder was subjected to wall-breaking treatment at 0° C., and the time of wall-breaking treatment was 30 minutes to obtain the extract residue of broken wall Ganoderma lucidum spore powder;

[0064] (2) Use purified water to extract the extract of the broken Ganoderma lucidum spore powder obtained in step (1) at 60°C under stirring conditions, the liquid-to-solid ratio of the extraction process is 25:1, and the extraction process takes 150 minutes , to obtain the extract after solid-liquid separation;

[0065] (3) The extract obtained in step (2) was left to stand at 25° C. for 9 hours, and then subjected to solid-liquid separation to obtain a supernatant;

[0066] (4) performing butterfly centrifugat...

Embodiment 3

[0069] This embodiment provides a method for preparing cell wall polysaccharides from Ganoderma lucidum spore powder raffinate, said method comprising the following steps:

[0070] (1) In the BFM100B superfine powder vibrating mill, the extract residue of Ganoderma lucidum spore powder was subjected to wall-breaking treatment at 5° C., and the time of wall-breaking treatment was 40 minutes to obtain the extract residue of Ganoderma lucidum spore powder;

[0071] (2) Use purified water to extract the ganoderma lucidum spore powder extract obtained in step (1) under stirring conditions at 95°C, the liquid-to-solid ratio of the extraction treatment is 15:1, and the extraction treatment time is 250min , to obtain the extract after solid-liquid separation;

[0072] (3) The extract obtained in step (2) was allowed to stand at 25° C. for 11 h, and then subjected to solid-liquid separation to obtain a supernatant;

[0073] (4) carry out butterfly centrifugation and tubular centrifuga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com