Seaweed master batch and manufacturing method of EVA foam

A production method, EVA26% technology, applied in the field of production of seaweed masterbatch and EVA foam, to achieve the effect of efficient and economical conversion, light weight and low bonding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

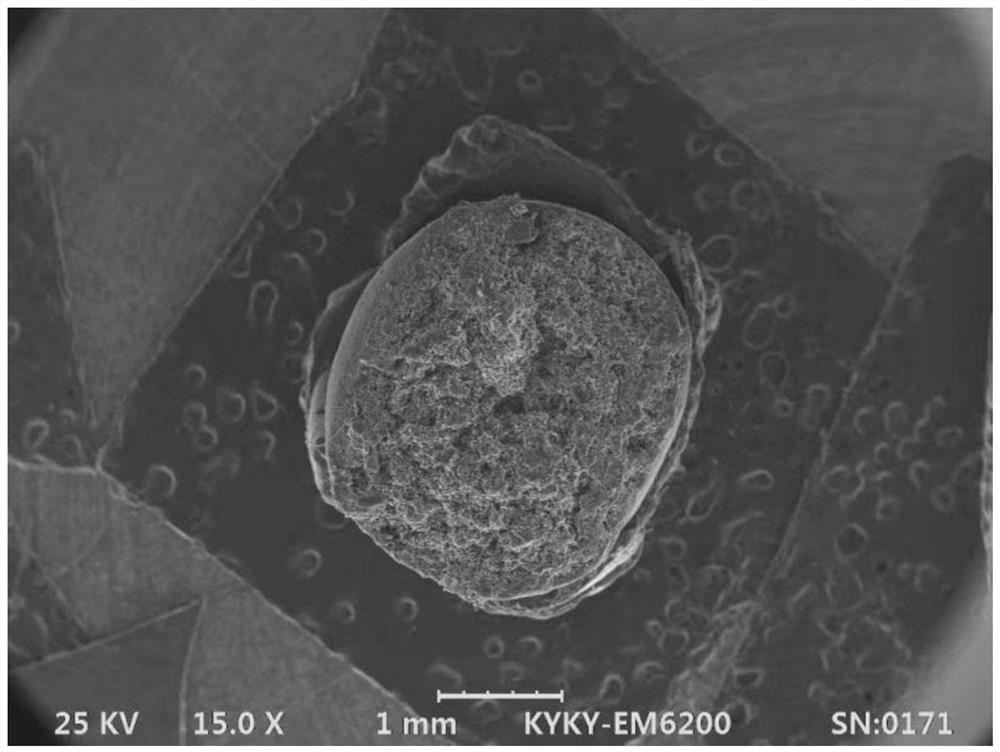

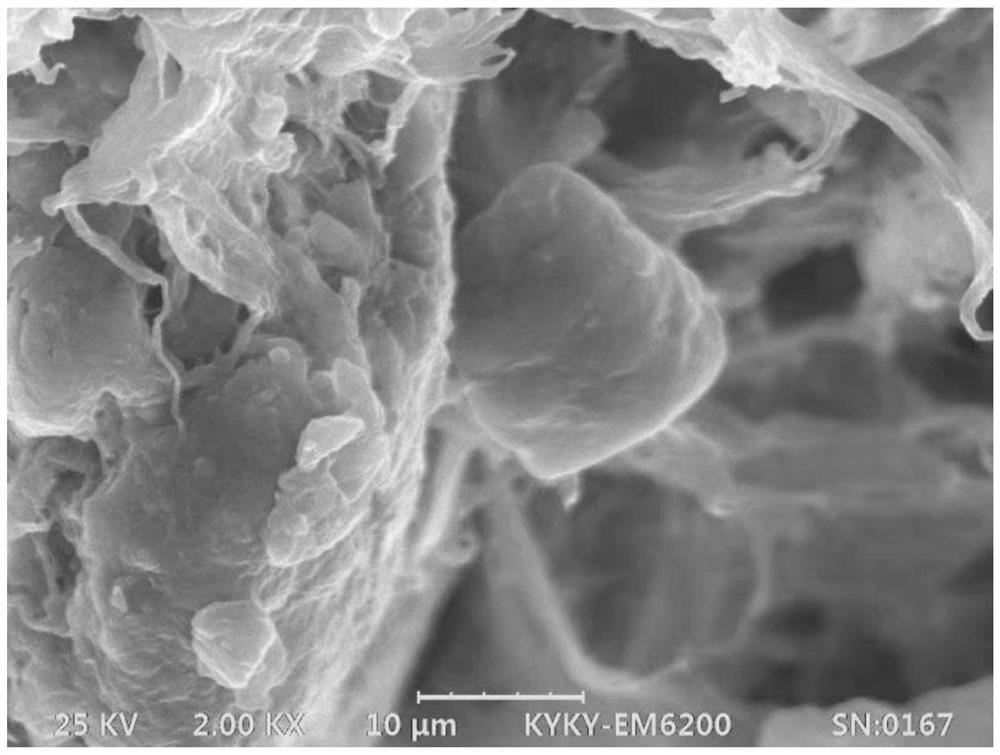

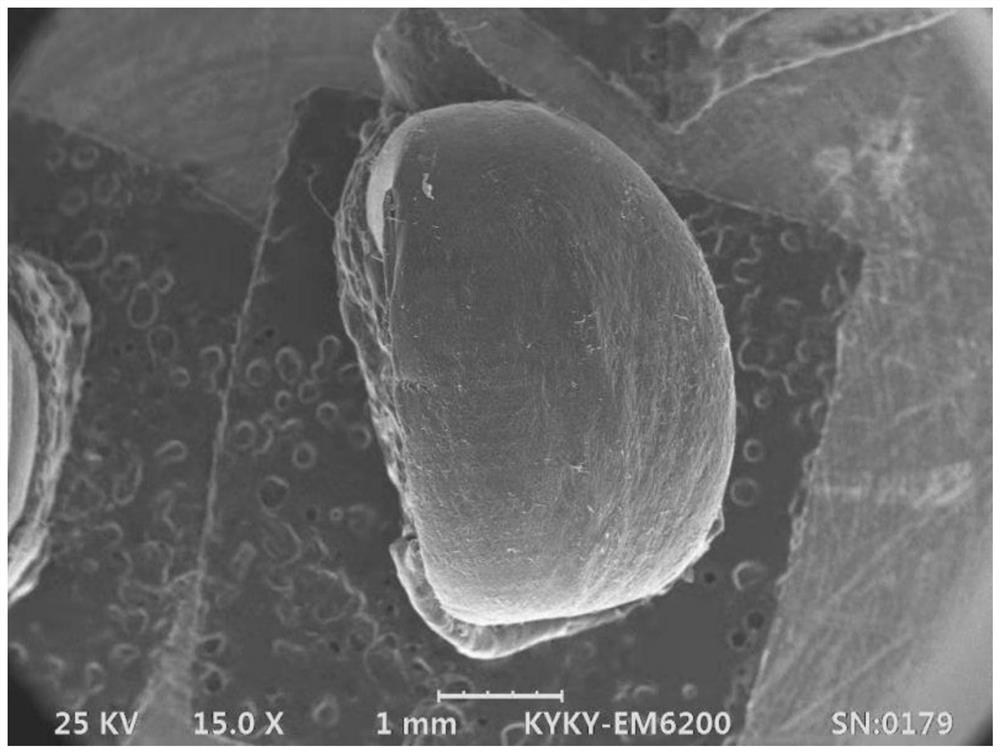

[0027] see Figure 1-4 , the present invention provides the following technical solutions: a seaweed masterbatch, wherein the ingredients and percentages of the seaweed masterbatch are: seaweed powder: 60-80%, EVA: 10-15%, zinc stearate: 3-5% , Aluminate: 1.5-2.5%, binder: 0.5-1%, antioxidant: 1-2%.

[0028] The seaweed powder is washed and desalted seaweed, and the seaweed is dehydrated and dried and crushed. The crushed seaweed powder is less than 300 mesh. minute.

[0029] The percentage content of each component of the seaweed masterbatch is: seaweed powder 60%, EVA 31%, zinc stearate 5%, aluminate 2.5%, binder 0.5%, antioxidant 1%.

Embodiment 2

[0031] In this embodiment: the percentage content of each component of seaweed masterbatch is: seaweed powder 65%, EVA 26%, zinc stearate 5%, aluminate 2.5%, binder 0.5%, antioxidant 1%.

Embodiment 3

[0033] In this embodiment: the percentage content of each component of seaweed masterbatch is: seaweed powder 70%, EVA 21%, zinc stearate 4.7%, aluminate 2%, binder 0.8%, antioxidant 1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com