Infrared light-permeable black plastic as well as preparation method and application thereof

A technology of infrared light and black material, applied in the field of infrared light-transmitting black plastic and its preparation, can solve the problems of uneven dispersion of color material, influence of infrared transmittance, cumbersome overall process, etc., and achieve the effect of good dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

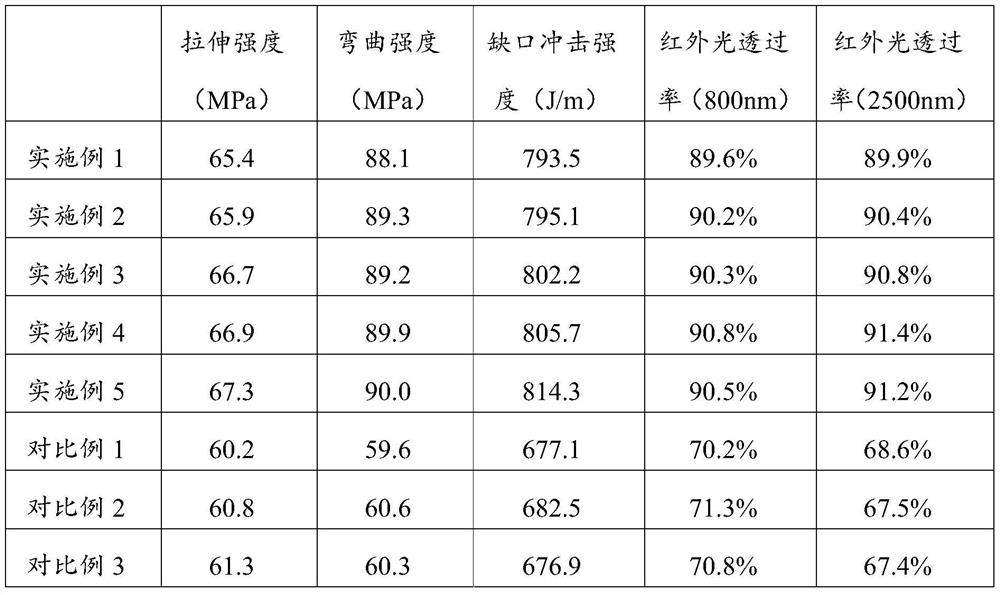

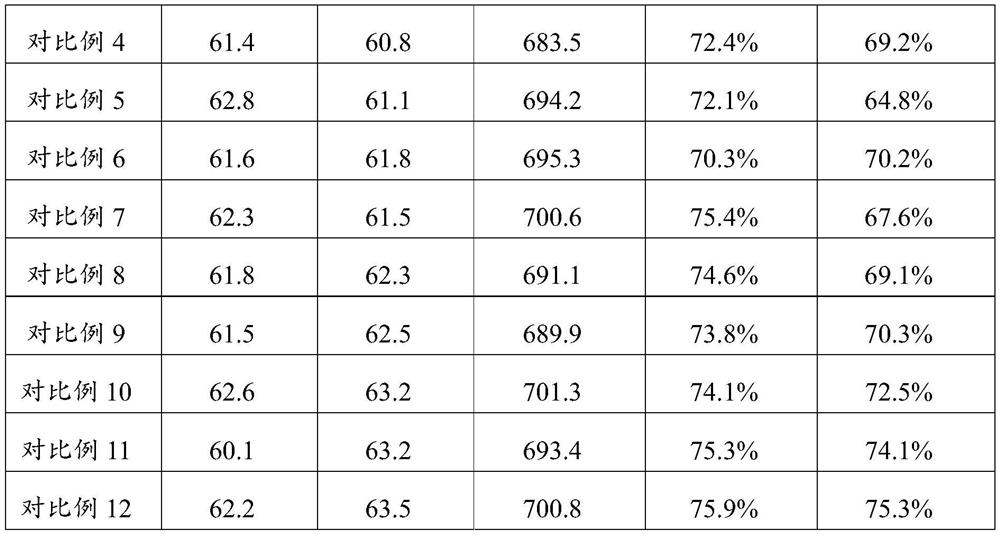

Examples

Embodiment 1

[0029] Black plastic that can transmit infrared light, containing the following components in mass percentage: 90% of carrier resin, 5% of black material powder, 3% of dispersant and 2% of lubricant, wherein, maleic anhydride grafted EVA in the carrier resin , The mass ratio of maleic anhydride grafted LDPE to ethylene vinyl acetate copolymer resin is 0.8:0.8:1.2.

[0030] Preparation:

[0031] According to the formula requirements, add maleic anhydride grafted EVA, maleic anhydride grafted LDPE and ethylene vinyl acetate copolymer resin to the reaction kettle in sequence at room temperature, stir and mix at a medium speed of 150r / min to obtain a carrier resin;

[0032] Add black material powder, dispersant and lubricant to the obtained carrier resin under medium-speed stirring state, and increase the stirring rate from 150-300r / min at medium speed to 500-650r / min at a stirring rate of 7-10r / min. Programmatically increase the temperature from room temperature to 40-45 °C at a...

Embodiment 2

[0035] Black plastic that can transmit infrared light, containing the following components in mass percentage: 87% of carrier resin, 6% of black material powder, 4% of dispersant and 3% of lubricant, wherein, maleic anhydride grafted EVA in the carrier resin , The mass ratio of maleic anhydride grafted LDPE to ethylene vinyl acetate copolymer resin is 0.8:0.8:1.

[0036] The preparation method is the same as in Example 1.

Embodiment 3

[0038] Infrared light-transmitting black plastic, containing the following components in mass percentage: carrier resin 85%, black material powder 7%, dispersant 5% and lubricant 3%, wherein, maleic anhydride grafted EVA in the carrier resin , The mass ratio of maleic anhydride grafted LDPE to ethylene vinyl acetate copolymer resin is 1:1:0.8.

[0039] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com