A kind of bipolar plate containing fluorine and its preparation method

A bipolar plate and plate technology, which is applied in the direction of fuel cells, regenerative fuel cells, electrical components, etc., can solve the problems of low impact strength and bending strength, high price, poor liquid resistance, etc., to improve uniformity, Improved quality and good dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

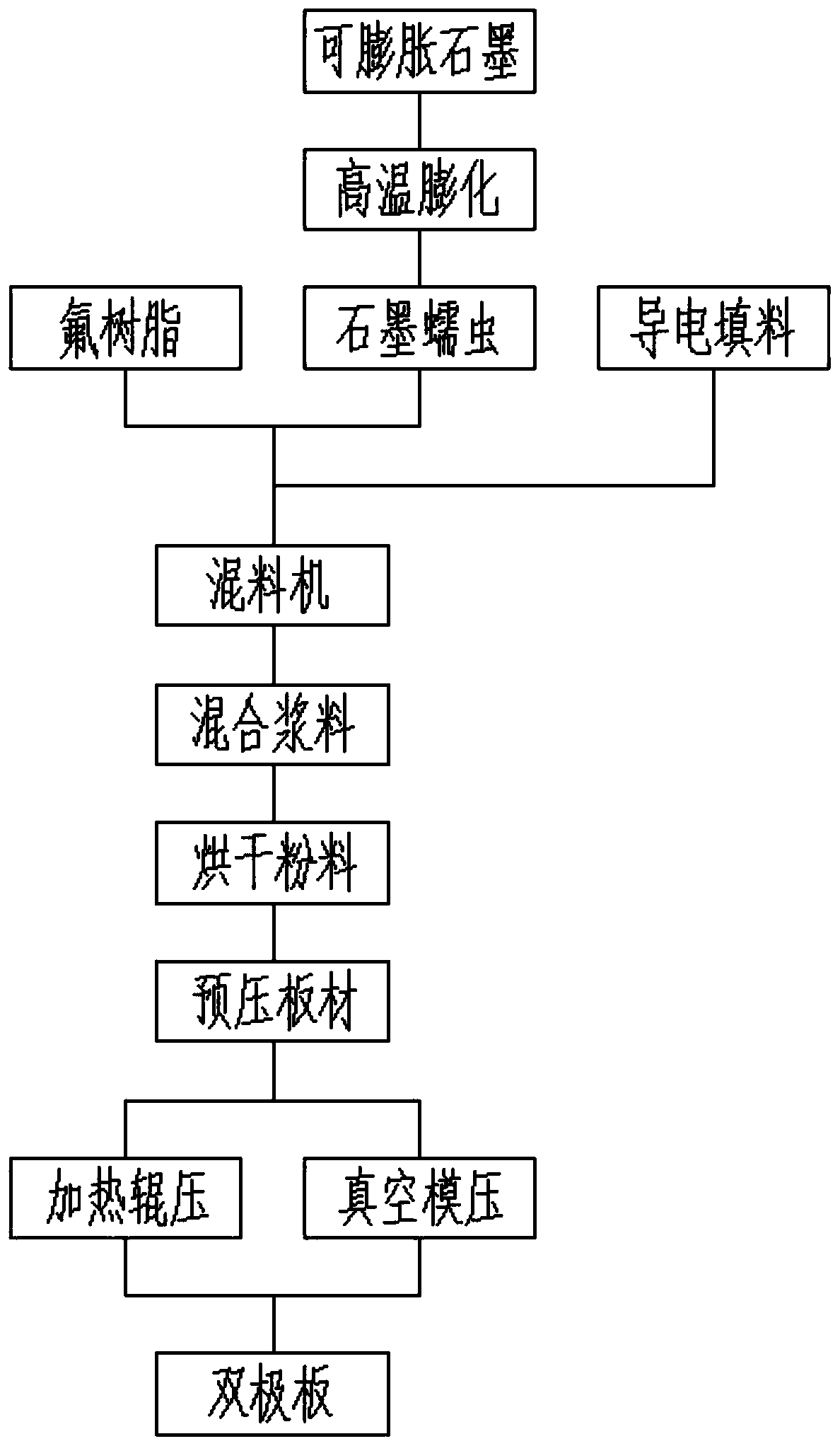

Method used

Image

Examples

Embodiment 1

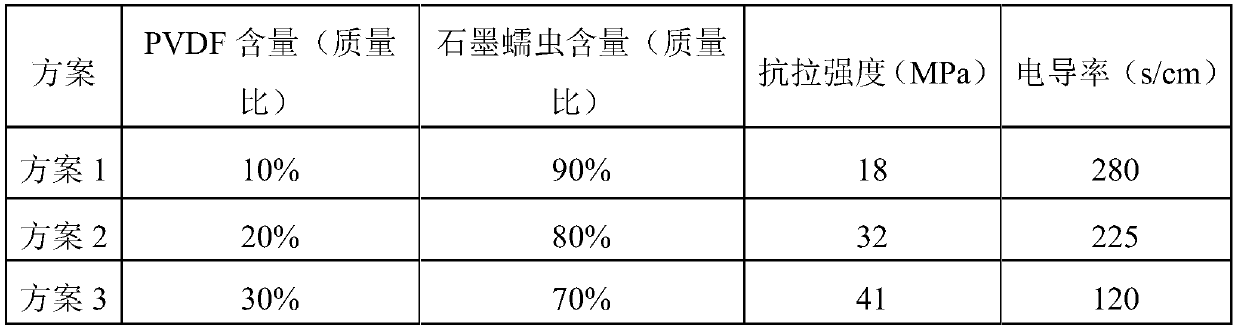

[0028] Embodiment 1 graphite worm+PVDF water-soluble emulsion

[0029] In step (1), expandable graphite with an expansion ratio of 200 and a mesh size of 80 meshes is used to expand graphite worms at a high temperature of 900°C to prepare graphite worms, and the prepared graphite worms are tested for water absorption, and the water absorption is measured to be about 2000%;

[0030] Step (2), get the graphite worm 80g that step (1) makes, get the PVDF water-soluble emulsion 100g that the mass ratio concentration is 20% (the original concentration of the finished product water-soluble emulsion that buys can negotiate with manufacturer as required and confirm, ex-factory concentration It can be controlled at about 10% to 60%) to prepare a sample with a PVDF content of 20%. According to the water absorption rate of graphite worms measured in step (1), 80g graphite worms need to absorb about 1600g of water. Add 1600g of deionized water to the emulsion to stir and dilute. Put the di...

Embodiment 2

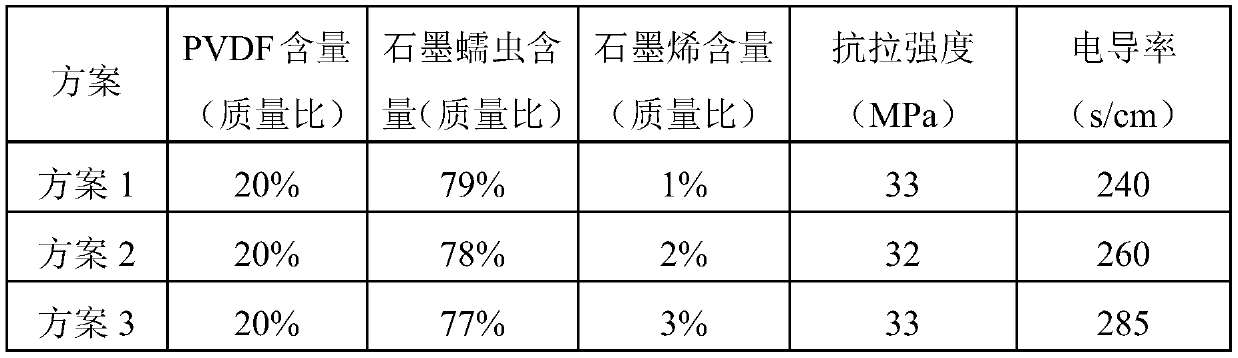

[0038] Embodiment 2 graphite worm+graphene+PVDF water-soluble emulsion

[0039] In step (1), expandable graphite with an expansion ratio of 200 and a mesh size of 80 meshes is used to expand graphite worms at a high temperature of 900°C to prepare graphite worms, and the prepared graphite worms are tested for water absorption, and the water absorption is measured to be about 2000%;

[0040]Step (2), get 78g of the graphite worms that step (1) makes, get graphene 2g (few layer graphene powder: 1~5 layers of samples, thickness 3~5nm, diameter 20μm), take mass ratio concentration and be 20% 100g of PVDF water-soluble emulsion (the original concentration of the purchased finished water-soluble emulsion can be confirmed through consultation with the manufacturer as required, and the ex-factory concentration can be controlled at about 10% to 60%) to prepare a sample with a PVDF content of 20% according to the steps (1) The measured water absorption rate of graphite worms is 78g. Gra...

Embodiment 3

[0048] Embodiment 3 graphite worm+carbon fiber+PVDF water-soluble emulsion

[0049] In step (1), expandable graphite with an expansion ratio of 200 and a mesh size of 80 meshes is used to expand graphite worms at a high temperature of 900°C to prepare graphite worms, and the prepared graphite worms are tested for water absorption, and the water absorption is measured to be about 2000%;

[0050] Step (2), get the graphite worm 78g that step (1) makes, get short carbon fiber 2g (length 0.2~0.5mm, diameter 10 μm left and right conductive short fibers), get the PVDF water-soluble emulsion 100g that mass ratio concentration is 20% ( The original concentration of the purchased finished product water-soluble emulsion can be confirmed through negotiation with the manufacturer as required, and the ex-factory concentration can be controlled at about 10% to 60%) to prepare a sample with a PVDF content of 20%. The water absorption rate of worms is 78g. Graphite worms need to absorb about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com