Corrosion-resistant high-strength light steel and preparation method

A corrosion-resistant, high-strength technology, applied in the direction of metal processing equipment, etc., can solve problems such as rolling mill performance requirements and complex processes, and achieve the effect of improving corrosion resistance, improving corrosion resistance, and inhibiting a large amount of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

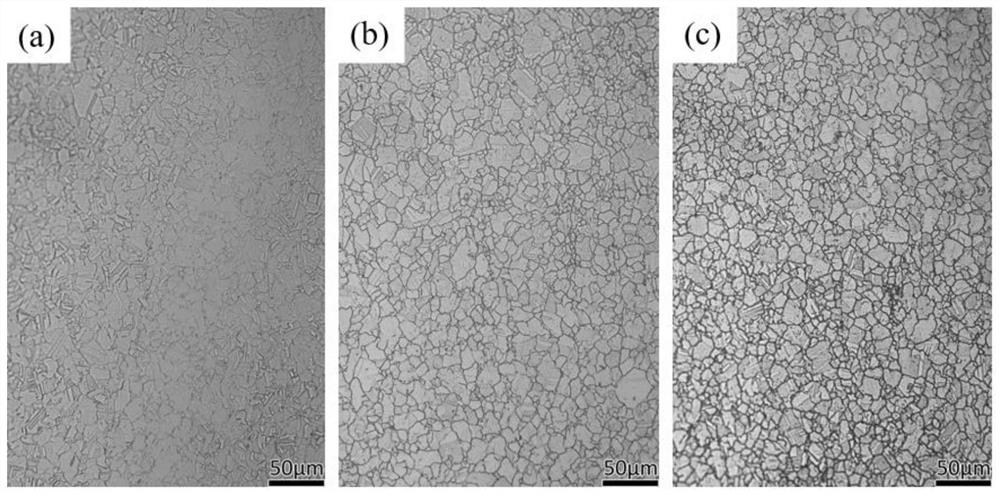

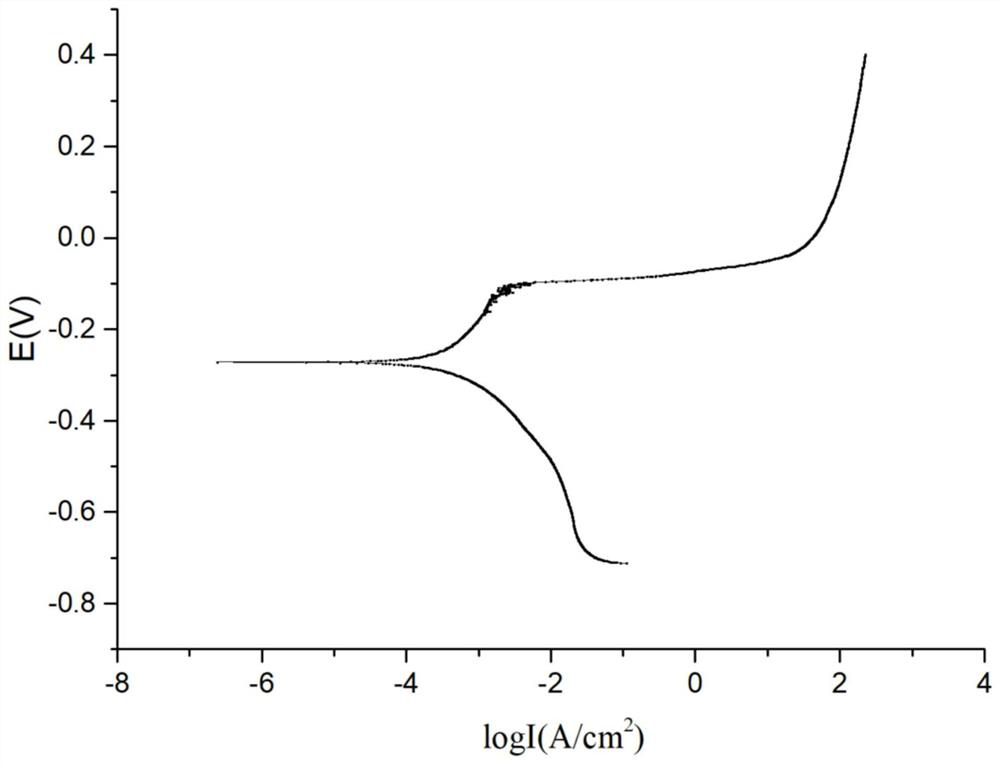

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below:

[0028] Table 1 is the composition list of each embodiment of the present invention;

[0029] Table 2 is the preparation process parameter list of each embodiment of the present invention;

[0030] Table 3 is a main performance list of each embodiment of the present invention.

[0031] Each embodiment of the present invention is prepared according to the following processes:

[0032] (1) Smelting: According to the composition ratio of corrosion-resistant high-strength light steel, it is smelted in a vacuum induction furnace and cast into ingots;

[0033] (2) Forging: the ingot is homogenized at 1100-1200°C for 2-5 hours, and after homogenization, it is forged into a billet with a thickness of 30-60mm;

[0034] (3) Hot rolling: heat the billet to 1180-1200°C and keep it warm for 2-4 hours. The homogenized billet is hot-rolled for 5-8 passes. The starting rolling temperature is 1130-1180°C, and the final rolling temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com