Aluminum-silicon alloy sputtering target material and preparation method and application thereof

An aluminum-silicon alloy and sputtering target technology, applied in the field of sputtering targets, can solve the problems of complexity, high heat preservation temperature, unfavorable production cost, etc., achieve good density, simplify the process flow, and facilitate the controllable adjustment of temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

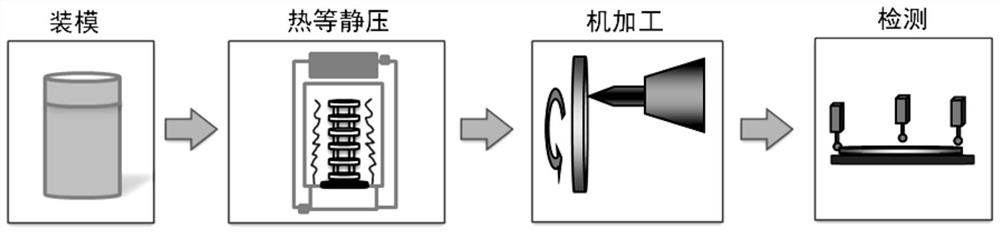

[0043] This embodiment provides an aluminum-silicon alloy sputtering target and its preparation method, such as figure 1 Shown, described preparation method comprises the following steps:

[0044] (1) filling and compacting aluminum-silicon alloy powder with an average particle size of 40 μm in a stainless steel sheath to obtain a first green body; the proportion of aluminum in the aluminum-silicon alloy powder is 50 wt %;

[0045] (2) weld the top cover of the stainless steel sheath, and place in the heating furnace, the first green body that step (1) gains is in absolute vacuum degree be 1 * 10 -2 Pa, and the degassing temperature is 300° C. to carry out vacuum degassing treatment for 6 hours to obtain the second green body;

[0046] (3) Place the stainless steel sheath in a hot isostatic pressing sintering furnace, and perform hot isostatic pressing on the second green body obtained in step (2) at an applied pressure of 200 MPa and a sintering temperature of 460°C for 5 ho...

Embodiment 2

[0050] This embodiment provides an aluminum-silicon alloy sputtering target and its preparation method, such as figure 1 Shown, described preparation method comprises the following steps:

[0051] (1) filling and compacting aluminum-silicon alloy powder with an average particle size of 20 μm in a stainless steel sheath to obtain a first green body; the proportion of aluminum in the aluminum-silicon alloy powder is 48.5wt%;

[0052] (2) weld the top cover of the stainless steel sheath, and place in the heating furnace, the first green body that step (1) gains is in absolute vacuum degree be 1 * 10 -4 Pa, and the degassing temperature is 250° C. to carry out vacuum degassing treatment for 7 hours to obtain the second green body;

[0053] (3) placing the stainless steel sheath in a hot isostatic pressing sintering furnace, and subjecting the second green body obtained in step (2) to hot isostatic pressing for 5.5 hours at an applied pressure of 250 MPa and a sintering temperatur...

Embodiment 3

[0057] This embodiment provides an aluminum-silicon alloy sputtering target and its preparation method, such as figure 1 Shown, described preparation method comprises the following steps:

[0058] (1) Filling and compacting aluminum-silicon alloy powder with an average particle size of 60 μm in a stainless steel sheath to obtain a first green body; the proportion of aluminum in the aluminum-silicon alloy powder is 51.5wt%;

[0059] (2) Weld the top cover of the stainless steel sheath, and place it in the heating furnace, and the first green body obtained in step (1) is 1Pa in absolute vacuum, and the degassing temperature is 350 ° C for 5h of vacuum degassing treatment, obtaining a second green body;

[0060] (3) Place the stainless steel sheath in a hot isostatic pressing sintering furnace, and perform hot isostatic pressing on the second green body obtained in step (2) at an applied pressure of 150 MPa and a sintering temperature of 500°C for 4 hours to obtain Aluminum sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com