Waterproof and breathable water sportswear fabric and preparation method thereof

A waterproof, breathable, sportswear technology, applied in the direction of biochemical fiber treatment, fiber type, textile and papermaking, etc., can solve the problems of unsustainable waterproof performance, poor hand feeling, coating peeling, etc., and achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The embodiment of the present invention relates to a preparation method of a waterproof and breathable water sportswear fabric, the water sportswear fabric includes a surface layer prepared from a waterproof and breathable fabric, and the waterproof and breathable fabric is interwoven with waterproof and breathable fibers as warp and weft yarns The preparation method of the waterproof breathable fabric comprises the following steps:

[0041] S1, spinning into fiber

[0042] Adding nano-zinc oxide or nano-titanium oxide into the polymer resin, and spinning through a melt spinning process after mixing uniformly to obtain the first modified fiber;

[0043] Wherein, the mixing mass ratio of the polymer resin to the nano-zinc oxide or nano-titanium oxide is 100: (4-15);

[0044] S2. Surface site modification

[0045] Weigh 90g of silane coupling agent KH570, add 1500ml of absolute ethanol, 32ml of deionized water, and 1ml of glacial acetic acid, and gradually heat up to 40...

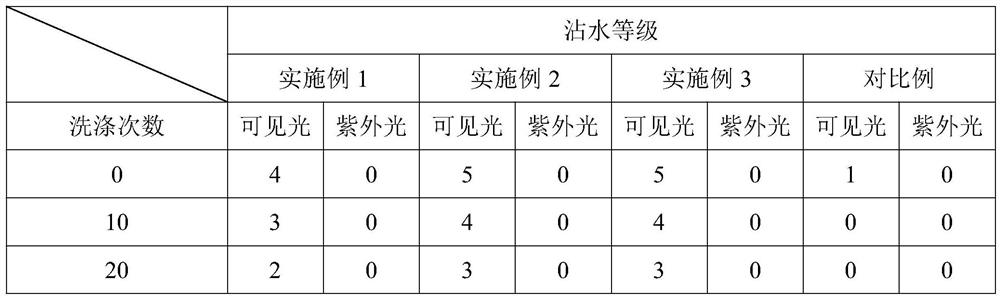

Embodiment 1

[0075] A method for preparing a waterproof and breathable water sportswear fabric, the water sportswear fabric includes a surface layer prepared from a waterproof and breathable fabric, the waterproof and breathable fabric is interwoven with waterproof and breathable fibers as warp and weft yarns, and the waterproof and breathable The preparation method of fabric comprises the following steps:

[0076] S1, spinning into fiber

[0077] Adding nano-zinc oxide or nano-titanium oxide into the polymer resin, and spinning through a melt spinning process after mixing uniformly to obtain the first modified fiber;

[0078] Wherein, the mixing mass ratio of the polymer resin to the nano-zinc oxide or nano-titanium oxide is 100:8;

[0079] S2. Surface site modification

[0080] Weigh 90g of silane coupling agent KH570, add 1500ml of absolute ethanol, 32ml of deionized water, and 1ml of glacial acetic acid, and gradually heat up to 40-45°C after fully stirring and dissolving. Immerse t...

Embodiment 2

[0100] A method for preparing a waterproof and breathable water sportswear fabric, the water sportswear fabric includes a surface layer prepared from a waterproof and breathable fabric, the waterproof and breathable fabric is interwoven with waterproof and breathable fibers as warp and weft yarns, and the waterproof and breathable The preparation method of fabric comprises the following steps:

[0101] S1, spinning into fiber

[0102] Adding nano-zinc oxide or nano-titanium oxide into the polymer resin, and spinning through a melt spinning process after mixing uniformly to obtain the first modified fiber;

[0103] Wherein, the mixing mass ratio of the polymer resin to the nano-zinc oxide or nano-titanium oxide is 100:8;

[0104] S2. Surface site modification

[0105] Weigh 90g of silane coupling agent KH570, add 1500ml of absolute ethanol, 32ml of deionized water, and 1ml of glacial acetic acid, and gradually heat up to 40-45°C after fully stirring and dissolving. Immerse t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com