Method for coating surface of porous metal with film

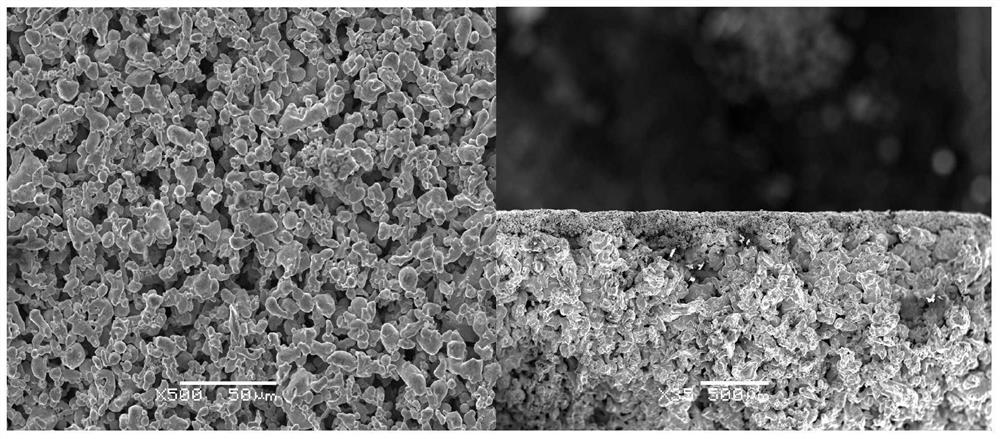

A porous metal and membrane-coated technology, which is applied in the direction of separation methods, metal processing equipment, chemical instruments and methods, etc., can solve the problems affecting the performance of porous metal membranes, increasing procedures, and residual plugs, etc., and achieves a simple and feasible process. The effect of improving filtration precision and uniform pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Prepare 8% PVB ethanol solution, heat and stir until completely dissolved. Then add 8% PVB solution, plasticizer, and 316L stainless steel powder with an average particle size of 10 um into the mixing tank according to the mass ratio of 10:1:15 and stir for 30 minutes to obtain a slurry A. Then heat and dissolve PVA and water at a ratio of 1:10 and stir evenly, and add polysiloxane defoamer at a ratio of 0.05ml / L to obtain slurry B.

[0041] 2. Spray the slurry A obtained in step 1 evenly on the PP base tape coated with silicone oil through an atomizer, scrape off the excess slurry with a scraper, and then put it in an oven for drying. The drying temperature is set at 80°C. Dry for 10 minutes; then use an atomizer to evenly spray the PVA solution obtained in step 1 on the film, control the thickness to 50um, and scrape off the excess PVA solution with a scraper.

[0042] 3. Put the film blank obtained in step 2 into the oven and start heating, set the heating rate t...

Embodiment 2-4

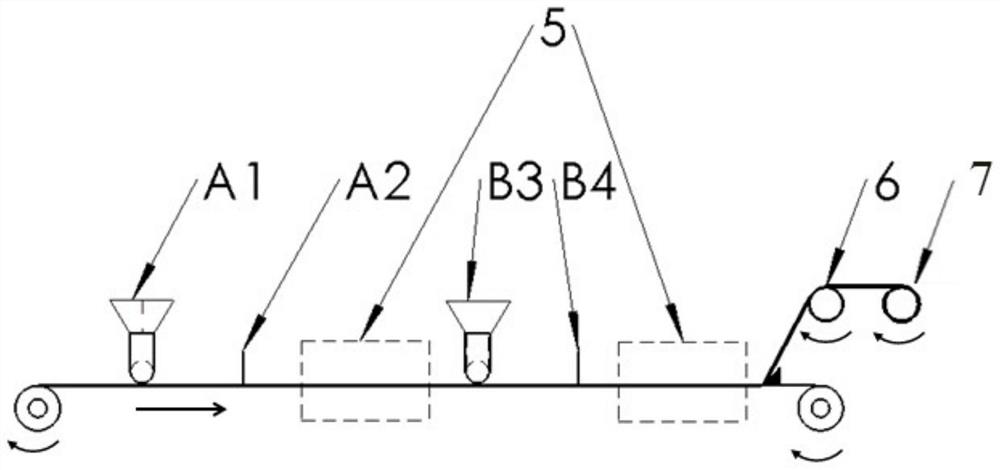

[0045] Embodiments 2-4 are described in conjunction with a porous metal surface coating device.

Embodiment 2

[0047] 1. In a water bath at 50°C, prepare 5% PVB ethanol solution, stir evenly until completely dissolved. Then PVB solution and plasticizer were mixed in a stirring tank for 5 minutes, and finally 316L stainless steel powder with an average particle diameter of 14um was added to continue stirring for 30 minutes, wherein the ratio of PVB solution, plasticizer and powder was 10:1:13, and finally Slurry A was obtained. Then heat and dissolve PVA and water at a ratio of 1:15 and stir evenly, and add polysiloxane defoamer at a ratio of 0.06ml / L to obtain slurry B.

[0048] 2. Pour the slurry A obtained in step 1 into figure 2 In the trough A of the tooling, pour the slurry B into the trough B of the tooling. Set the speed of the base belt to 0.2m / min, open the opening in the trough A, apply the slurry evenly on the PP base belt under the action of the coating roller, scrape off the excess slurry with the scraper A; then, the film enters the first Dry in an oven, and set the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com