Novel colorful dry powder coating

A dry powder coating and color technology, applied in the field of new color dry powder coatings, can solve problems such as differences in coating film performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

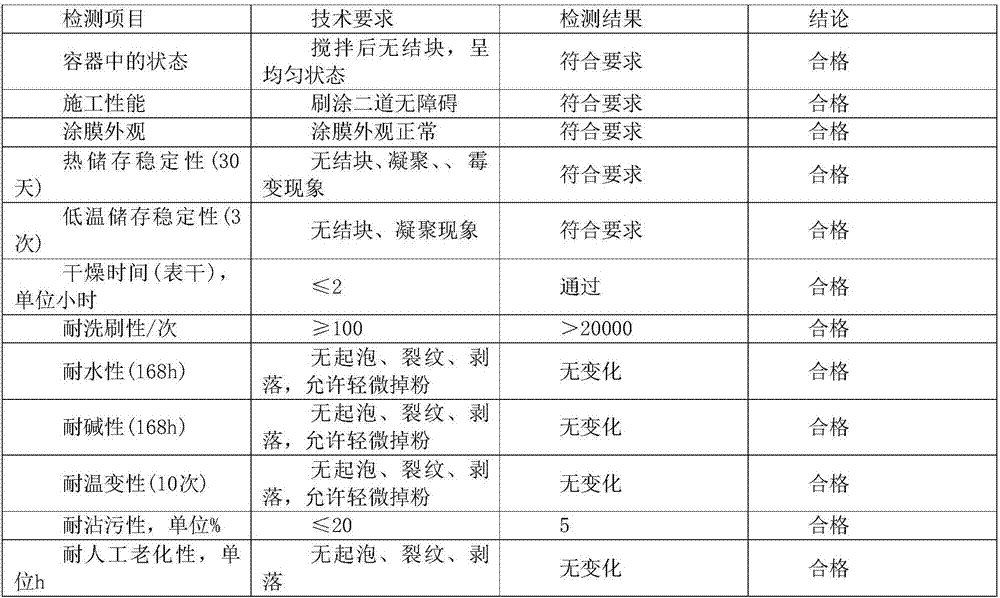

Image

Examples

Embodiment 1

[0030] The novel color dry powder coating that present embodiment provides, comprises the component of following parts by weight:

[0031] (1) Ordinary Portland cement: 500 parts;

[0032] (2) heavy calcium carbonate: 300 parts;

[0033] (3) Talcum powder: 100 parts;

[0034] (4) titanium dioxide: 20 parts;

[0035] (5) Iron oxide pigment: 50 parts;

[0036] (6) Hydroxypropyl cellulose ether: 3 parts;

[0037] (7) Modified redispersible polymer resin latex powder: 30 parts;

[0038] (8) Sodium bentonite: 3 parts;

[0039] (9) Ferrous sulfate: 3 parts.

[0040] The preparation method of modified redispersible polymer resin latex powder is as follows:

[0041] Mix redispersible latex powder, polypropylene, and styrene-acrylonitrile copolymer in parts by weight of 10:5:3, put them into a reaction kettle, react at 150 degrees Celsius for 1 hour, dry and pulverize.

Embodiment 2

[0043] The novel color dry powder coating that present embodiment provides, comprises the component of following parts by weight:

[0044] (1) Ordinary Portland cement: 400 parts;

[0045] (2) heavy calcium carbonate: 200 parts;

[0046] (3) Talcum powder: 50 parts;

[0047] (4) titanium dioxide: 10 parts;

[0048] (5) Iron oxide pigment: 20 parts;

[0049] (6) Hydroxypropyl cellulose ether: 2 parts;

[0050] (7) Modified redispersible polymer resin latex powder: 20 parts;

[0051] (8) Sodium bentonite: 2 parts;

[0052] (9) Ferrous sulfate: 2 parts.

[0053] The preparation method of modified redispersible polymer resin latex powder is as follows:

[0054] Mix redispersible latex powder, polypropylene, and styrene-acrylonitrile copolymer in parts by weight of 10:2:1, put them into a reaction kettle, react at 130 degrees Celsius for 2 hours, dry and pulverize.

[0055] Add the colored dry powder paint prepared in the above examples into water, stir evenly, and then car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com