Fabricated composite structure joint connecting system

A combined structure and node connection technology, which is applied in the direction of building structure and construction, can solve the problems of inability to realize full assembly, prolong the progress, increase the construction process, etc., and achieve the effects of enhanced connection stability, easy operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

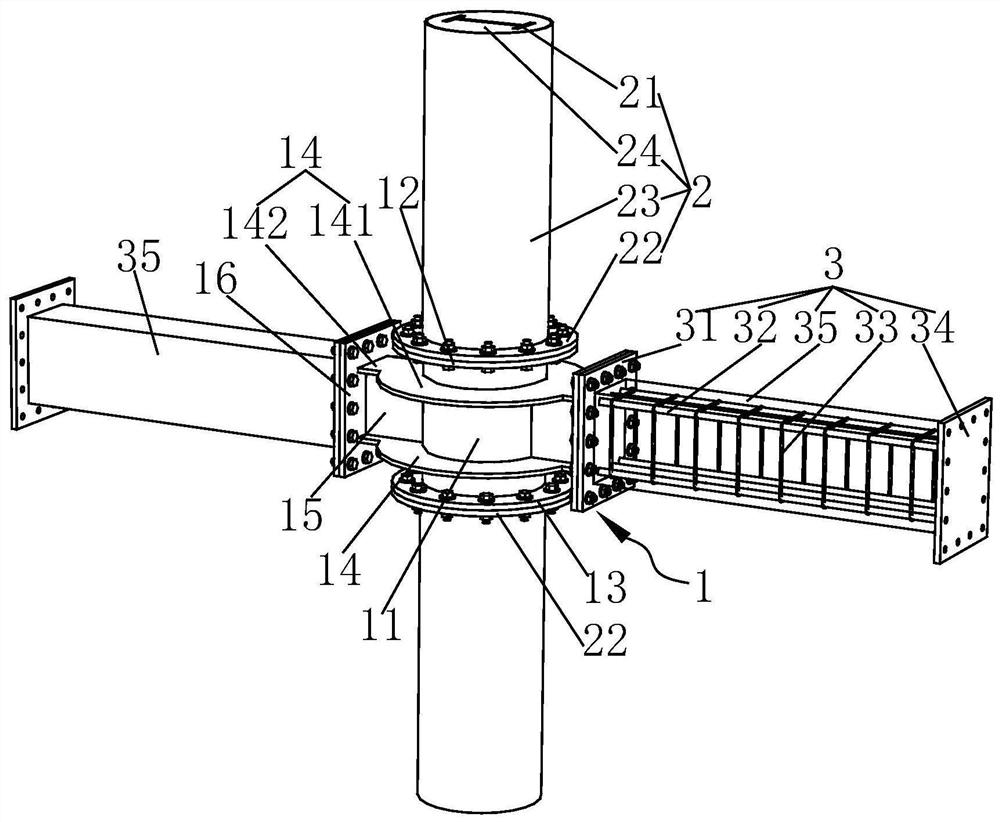

[0037] In this embodiment 1, the assembled beam 3 includes a first beam end plate 31, steel bars 32, stirrups 33, a second beam end plate 34 and a beam wrapping layer 35; the two opposite assembled beams 3 are the same of. The first beam end plate 31 is connected to the connecting beam end plate 16; a plurality of steel bars 32 are distributed between the first beam end plate 31 and the second beam end plate 34; a plurality of stirrup bars 33 sets The plurality of steel bars 32 are distributed at intervals along the length direction of the steel bars 32 ; the beam wrapping layer 35 is wrapped on the outside of the steel bars 32 and stirrup bars 33 . The assembled beam 3 is formed by the first beam end plate 31, steel bars 32, stirrups 33, the second beam end plate 34 and the beam wrapping layer 35, and multiple beams are arranged between the first beam end plate 31 and the second beam end plate 34. A steel bar 32 and a plurality of stirrups 33 are convenient to strengthen the...

Embodiment 2

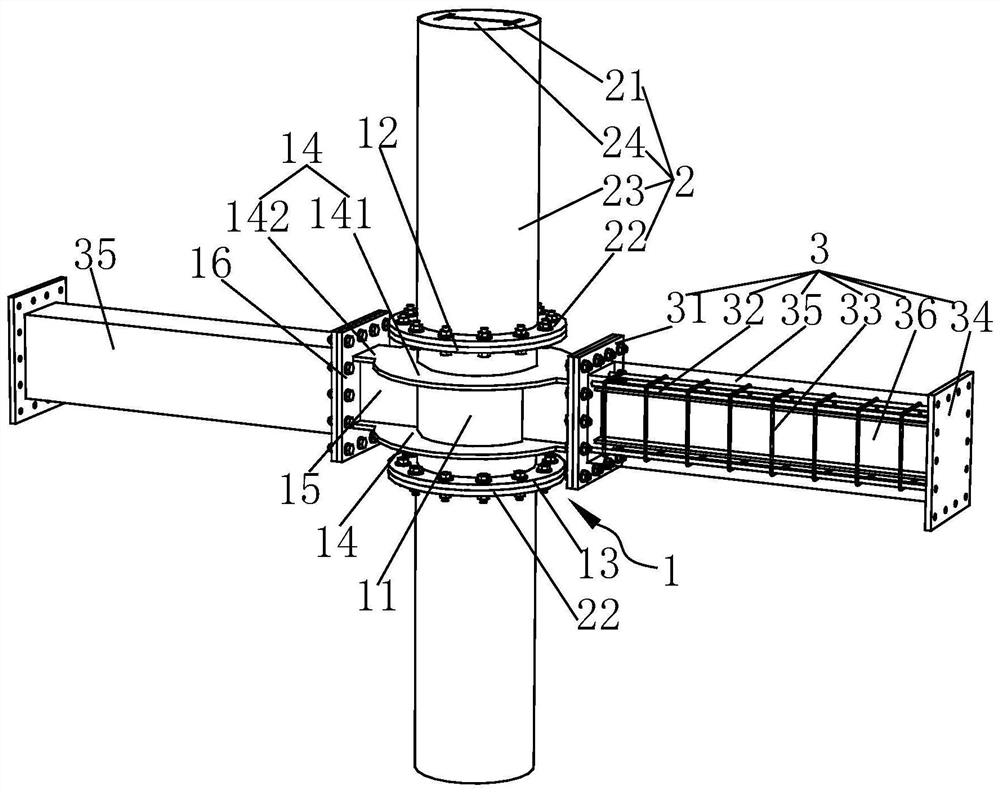

[0040] In Embodiment 2, the prefabricated composite structure node connection system of this implementation is basically the same as that of Embodiment 1, the difference is that the prefabricated beam 3 includes a first beam end plate 31, steel bars 32, section steel 36, stirrups 33, The second beam end plate 34, the beam wrapping layer 35; the first beam end plate 31 is connected to the connecting beam end plate 16; the section steel 36 is connected to the first beam end plate 31 and the second beam end plate 34; a plurality of steel bars 32 are connected between the first beam end plate 31 and the second beam end plate 34; among the multiple steel bars 32, half of the steel bars 32 are distributed in the section steel 36; the other half is distributed below the shaped steel 36; On the basis of the prefabricated beam 3 in embodiment 1, adding section steel 36 helps to further strengthen the mechanical strength and hardness of the prefabricated beam 3, so that the overall stre...

Embodiment 3

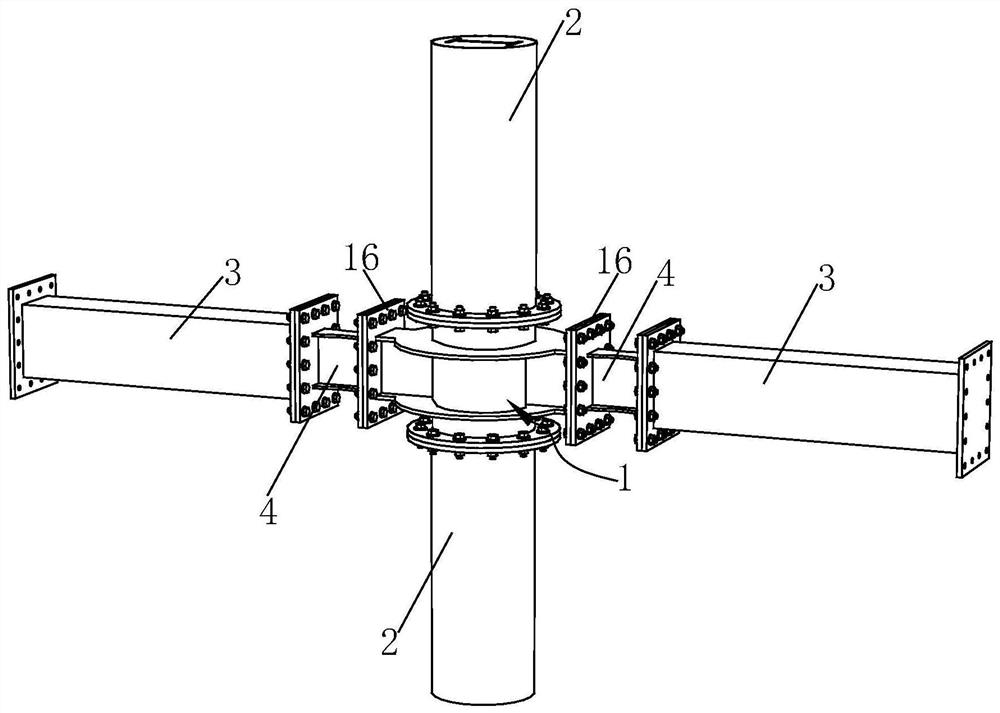

[0042] In Embodiment 3, the prefabricated composite structure node connection system of this implementation is basically the same as all the above-mentioned embodiments, the difference is that the connecting beam end plate 16 passes through an energy dissipation and shock absorbing device 4 that can be used for energy dissipation and shock absorption It is connected with the prefabricated beam 3 . The energy dissipation and shock absorbing device 4 is arranged between the connecting beam end plate 16 and the assembled beam 3, and is connected by high-strength bolts. The structure is simple and the installation is convenient. The structural node connection system forms a prefabricated energy-dissipating and shock-absorbing structural system, thereby reducing damage to important components in the structure during earthquakes.

[0043] In addition, the constraining members of beams and columns can adopt various cross-sectional forms, such as square, circular, etc., and their mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com