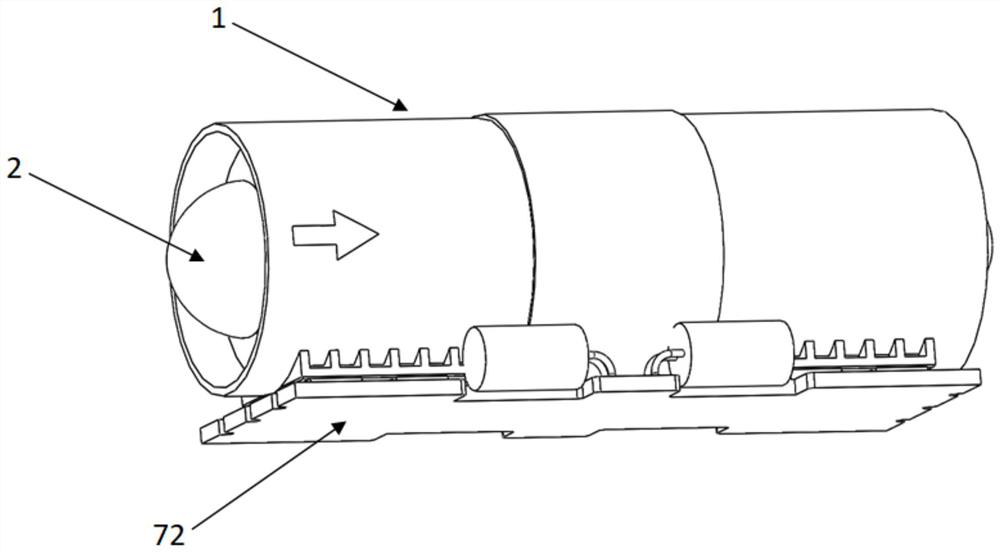

Gas compressor and handheld dust collector

A compressor and pressure sensor technology, applied in vacuum cleaners, machines/engines, mechanical equipment, etc., can solve the problems of high wind noise, narrow high-efficiency fan working area, increased fan diameter and volume, etc., to achieve low operating wind noise, Small size and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

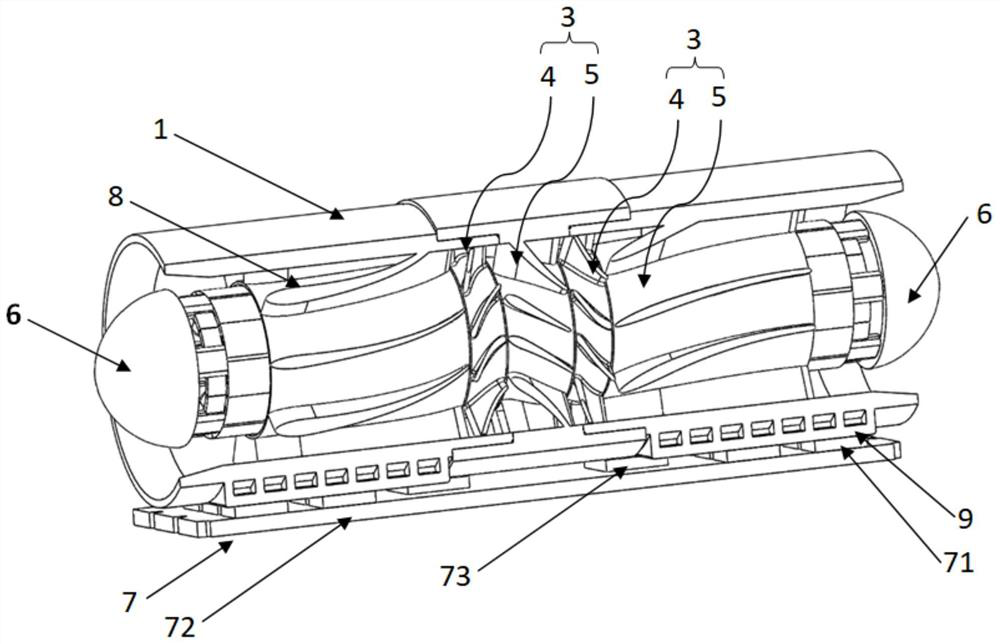

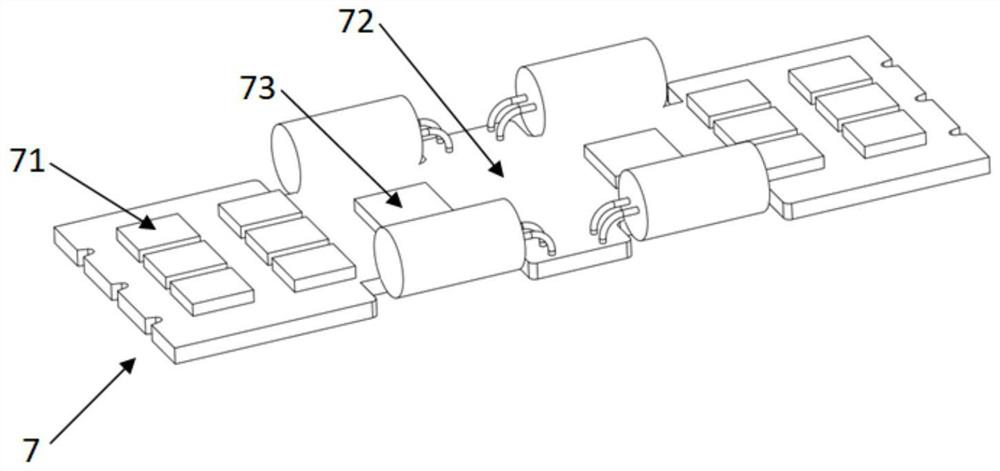

[0042] refer to Figure 5 , as an example, in this embodiment, an axial-flow compressor is provided. This compressor is an axial-flow compressor, which includes two stages of moving and stationary blade units, which are respectively the first stage of moving and stationary blade units 31 and the second stage of The moving and stationary vane unit 32, the guide vane, the first stage of the moving and stationary vane unit 31 and the second stage of the moving and stationary vane unit 32 are arranged in sequence along the airflow direction, and the housing includes the first housing 11, the second housing 12 and the connecting housing 13 , the first-stage moving and stationary blade unit 31 includes a first-stage moving blade 311 and a first-stage stationary blade 312 , the second-stage moving and stationary blade unit 32 includes a second-stage moving blade 321 and a second-stage stationary blade 322 , and the guide vanes are connected to The inner wall of the first housing 11, ...

Embodiment 2

[0046] refer to Figure 6 , as an example, in this embodiment, a mixed-flow compressor is provided, the compressor is a mixed-flow compressor, in which the first-stage moving blade 3110 and the second-stage moving blade 3210 both adopt the structure of a mixed-flow fan, For other structures, refer to the above-mentioned embodiment 1, and details are not repeated here. Similarly, the moving blades with the structure of the mixed-flow fan also have the characteristics of large air volume, small motor outer diameter, small volume, low operating speed, low operating wind noise, widening the efficient working area of the vacuum cleaner, and high working efficiency.

[0047] Of course, according to the actual situation, axial flow and mixed flow blades can be used in combination, that is, the form of the first-stage axial flow blade and the first-stage mixed flow blade. In addition, centrifugal type blades can also be used in this inventive idea.

[0048] In the second aspect of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com