Heat preservation structure and method of overhead pipeline support of near-zero thermal bridge

A technology for overhead pipelines and thermal bridges, applied in the field of thermal insulation of heating steam pipelines, can solve problems such as insulation layer sinking and deterioration of pipeline thermal insulation performance, and achieve the effects of reducing thermal bridges, easy installation and maintenance, and guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments.

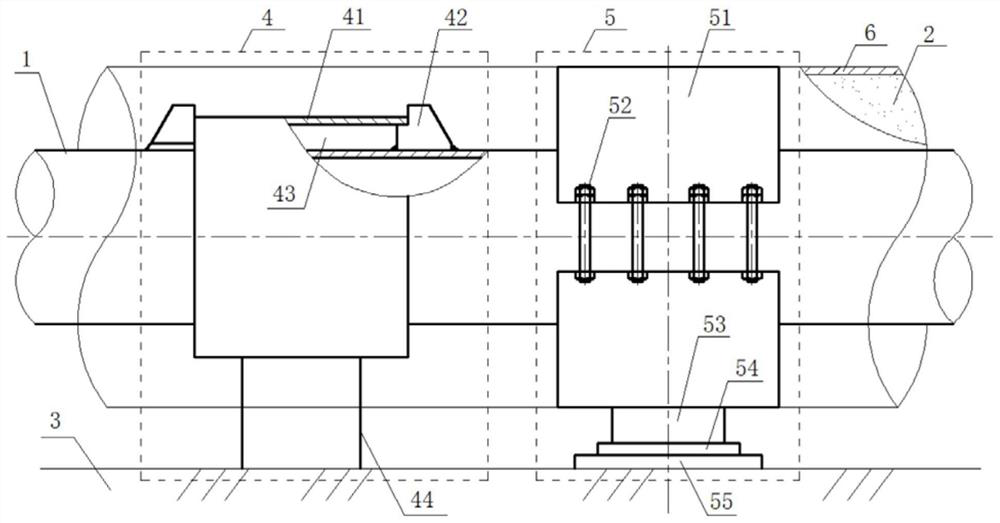

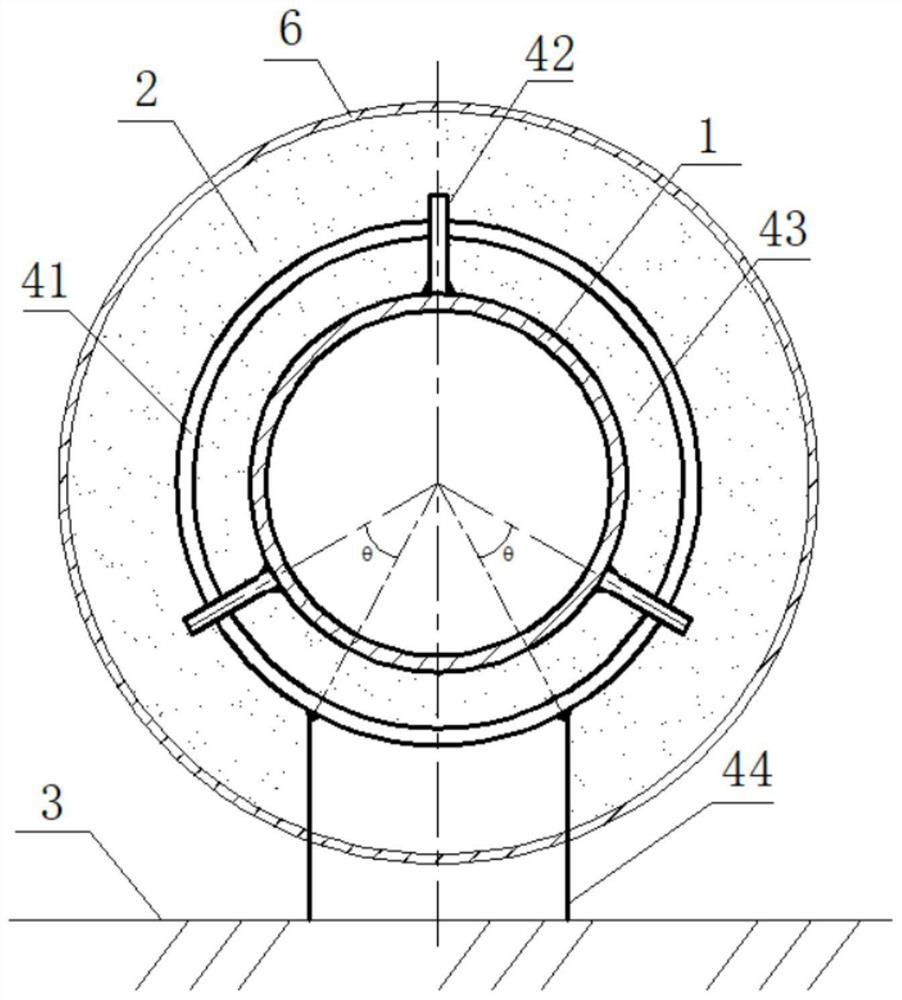

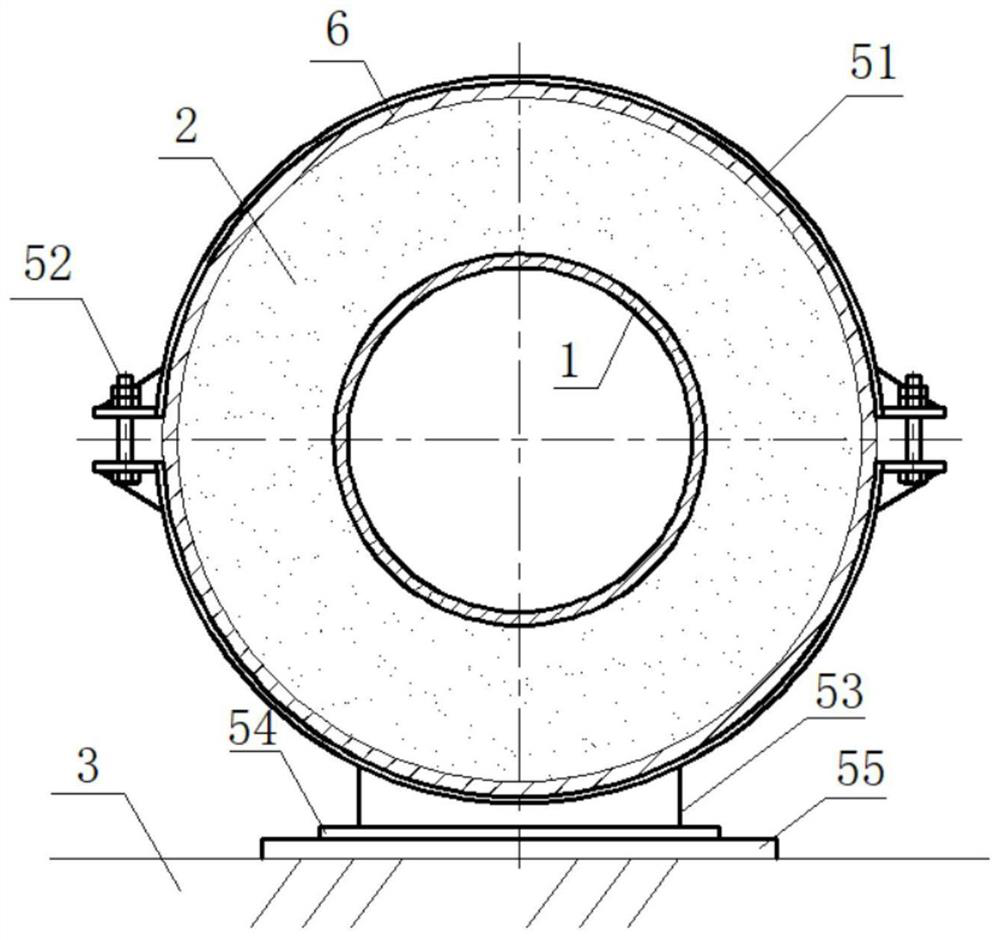

[0029] Such as figure 1 As shown, in a preferred embodiment of the present invention, a near-zero thermal bridge overhead pipeline support insulation structure is provided, which includes a working tube 1, an insulation layer 2, a base 3, an energy-saving insulation fixed bracket 4, a zero-heat Bridge sliding bracket 5 and outer protection steel plate 6. The heat preservation layer 2 and the outer protection steel plate 6 are sequentially laid on the outside of the working pipe 1 to form the heat preservation pipe. The heat preservation layer 2 wraps around the outer periphery of the work pipe 1 to block the heat exchange between the work pipe 1 and the external environment; the outer protection steel plate 6 surrounds the heat preservation pipe. The outer side of the layer 2 is used to provide a fixed point for the zero therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com