Power station boiler steam soot blowing system and intelligent leak detection identification method thereof

A soot blowing system, power plant boiler technology, applied in lighting and heating equipment, using liquid/vacuum degree for liquid tightness measurement, by measuring the increase and deceleration rate of fluid, etc., can solve the problems of poor reliability and complex logic, and achieve Strong practicability and the effect of overcoming time lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is further described below in conjunction with accompanying drawing:

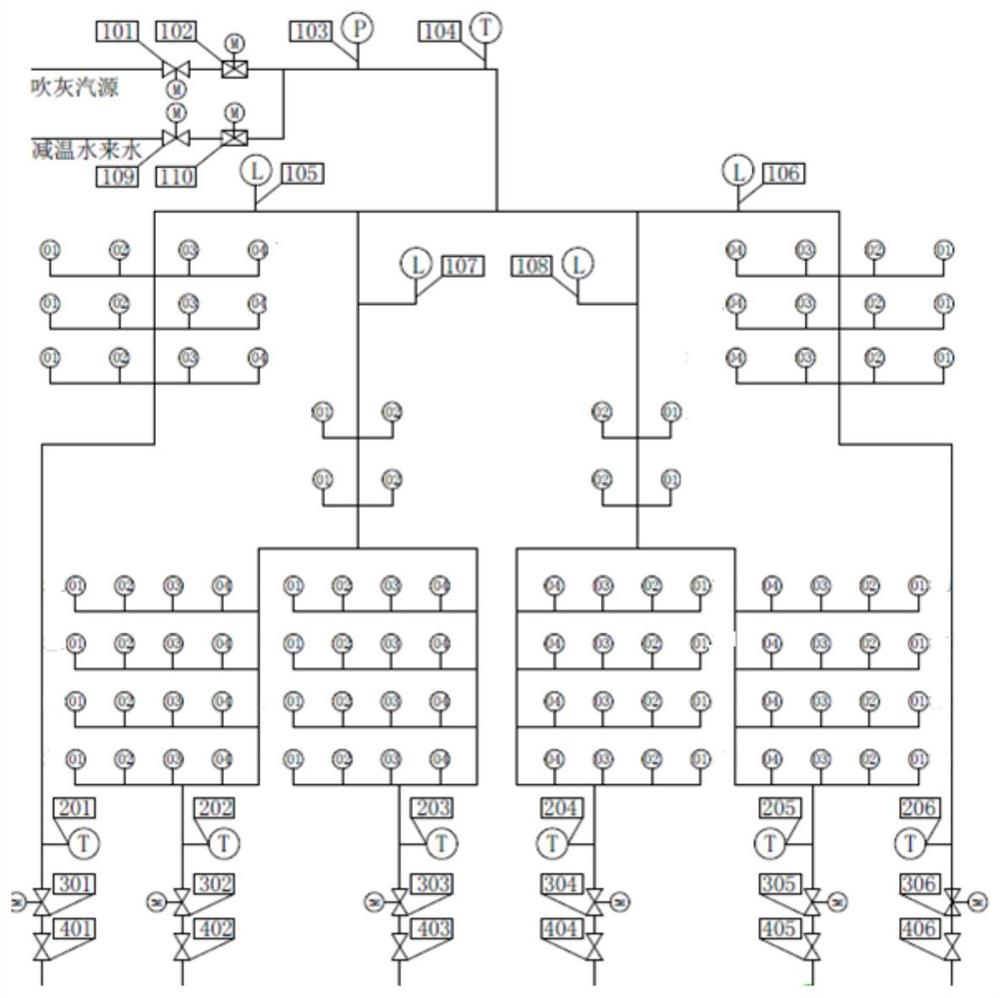

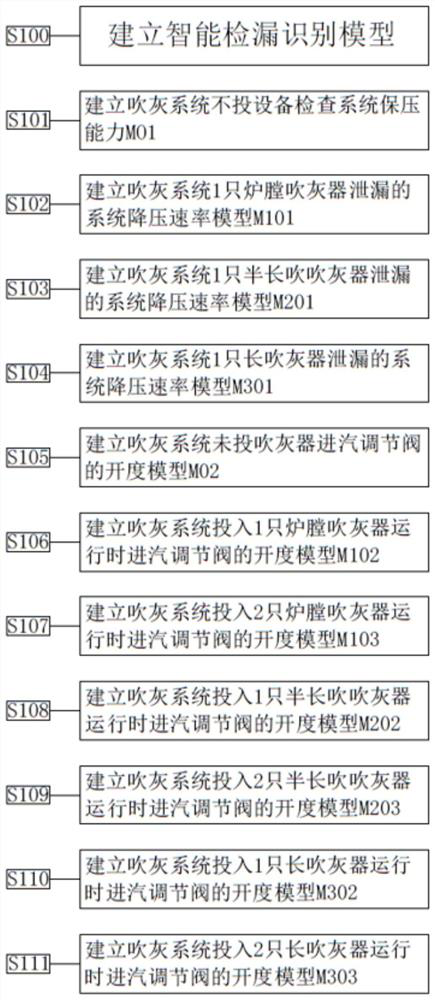

[0046] A system process for intelligent leak detection and identification of power plant boiler steam soot blowing system such as figure 1 As shown, the principle of leak detection and identification is as follows figure 2 As shown, the boiler coal quantity, unit load and boiler MFT signals are extracted in the unit DCS control system.

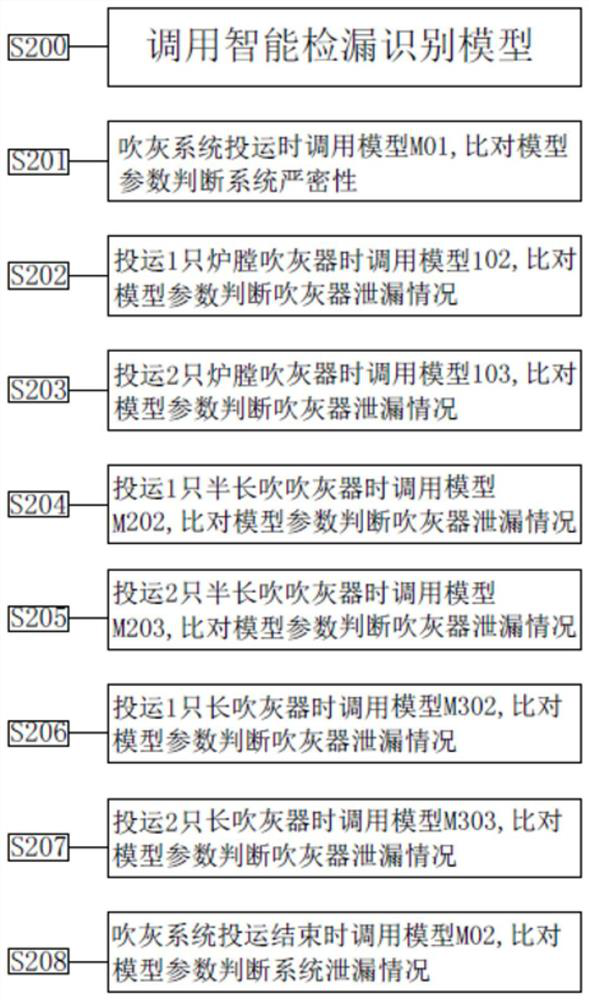

[0047] Draw up the identification program, after starting the soot blowing program, the program will automatically open the 301, 302, 303, 304, 305, 306 drain control valves

[0048] Establish a start-up leak detection identification program. If the program detects that the boiler is not ignited in the current state, the program does not judge the start-up permission conditions of the soot blowing system, and directly executes the main program and performs simulation, that is, the program automatically opens 301, 302, 303, and 304 , 305, 306 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com