Device and method for detecting microsphere defects by combining dark field imaging with space phase-shifting interference

A phase-shifting interference and dark-field imaging technology, which is applied in measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve problems such as low detection efficiency, environmental factors, and poor effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

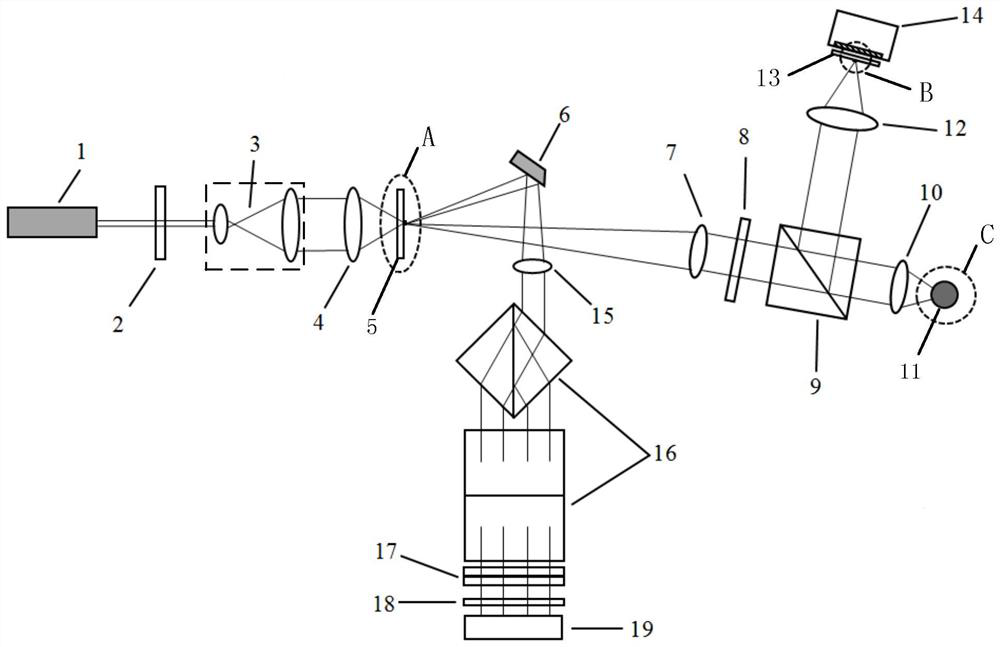

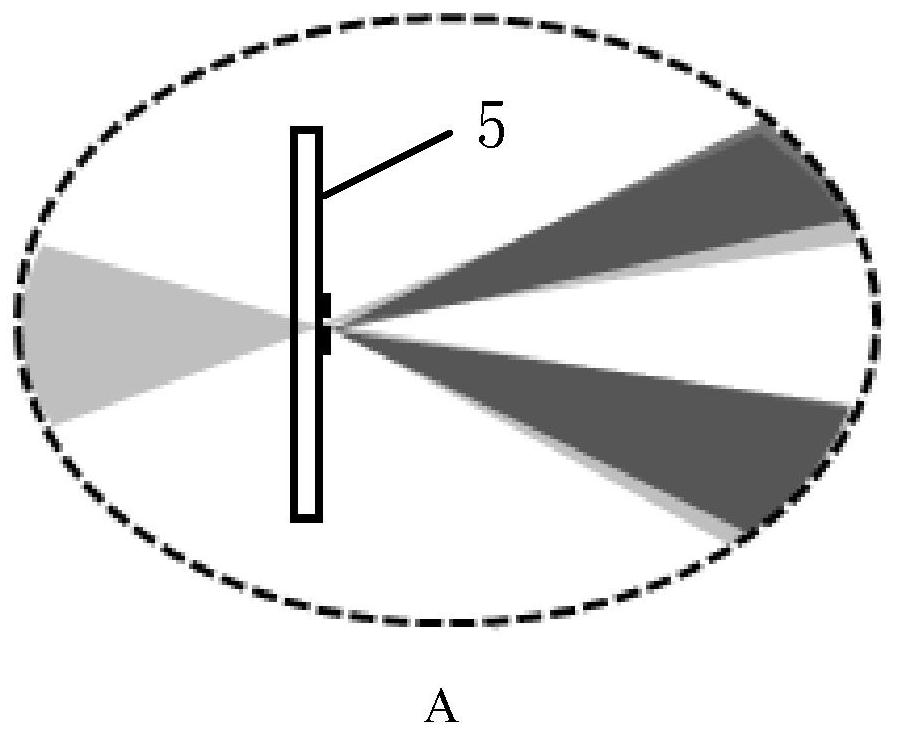

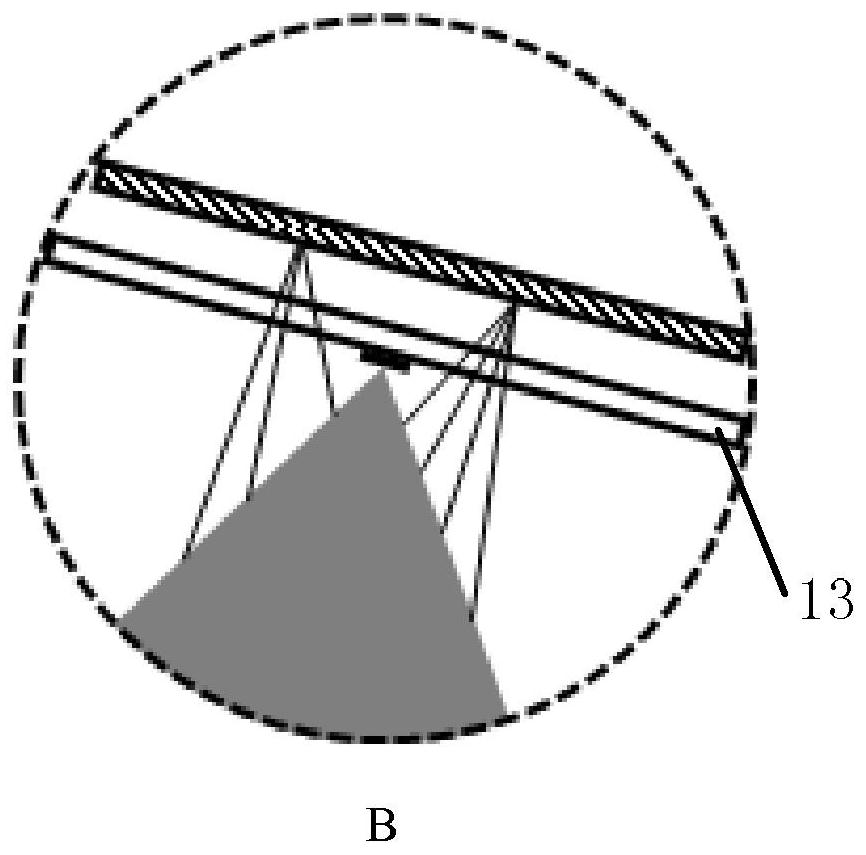

[0018] DETAILED DESCRIPTION One: Refer to Figure 1 to 6 Specifically, the present embodiment, the microsphere defect detecting device interference interference interference, including: laser 1, λ / 2 wave plate 2, 4F beam system 3, high Microscopic mirror 4, pinhole mirror 5, D-shaped mirror 6, first alignment lens 7, λ / 4 wave plate 8, spectroscopic prism 9, microscopy, imaging lens 12, mask plate 13, imaging CCD 14, a second ratio direct lens 15, a split prism group 16, a wavefront group 17, a detector 18, a large-faced high speed camera 19, and a suspension structure.

[0019] The laser 1, λ / 2 wave plate 2, 4F beam system 3, high-magnification microscope 4 and pinhole mirror 5 are sequentially arranged along the same optical axis, laser 1, λ / 2 wave plate 2, 4F beam system 3 The high-grade microscope 4 is located on the incident light direction of the pinhole mirror 5, and the laser 1 is permitted in the direction of the light surface of the pinhole mirror 5. The spectrosco...

specific Embodiment approach 2

[0029] DETAILED DESCRIPTION OF THE INVENTION 2: The microsphere defect detection method of the dark field imaging binding spatial shift interference interference is implemented based on the following device, including: λ / 2 wave plate 2, 4F beam system 3, high multiplier display Microscope 4, pinhole mirror 5, D-shaped mirror 6, first aligned straight lens 7, λ / 4 wave plate 8, spectroscopic prism 9, microscopy objective, imaging lens 12, mask plate 13, imaging CCD14 , The second ratio direct lens 15, the spectroscopic prism group 16, the wavefill set 17, the detector 18, and the largermost array high speed camera 19.

[0030] The linear polarizing light is sequentially transmitted through the λ / 2 wave plate 2, 4F beam system 3 and the high-enhanced microscope 4, and the light-diffracted light diffraced by the pinhole mirror 5 is D. The mirror 6 is reflected to the second ratio direct lens 15, and the reference light is constituted by the second ratio straight lens 15. The lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com