An intelligent production method of power grid device

A production method and power grid technology, applied in the direction of electrical program control, comprehensive factory control, program control, etc., can solve the problems of opaque production process, chaotic workshop layout, and impact on production quality, so as to reduce the cost of later error correction and prevent manual errors. installation, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

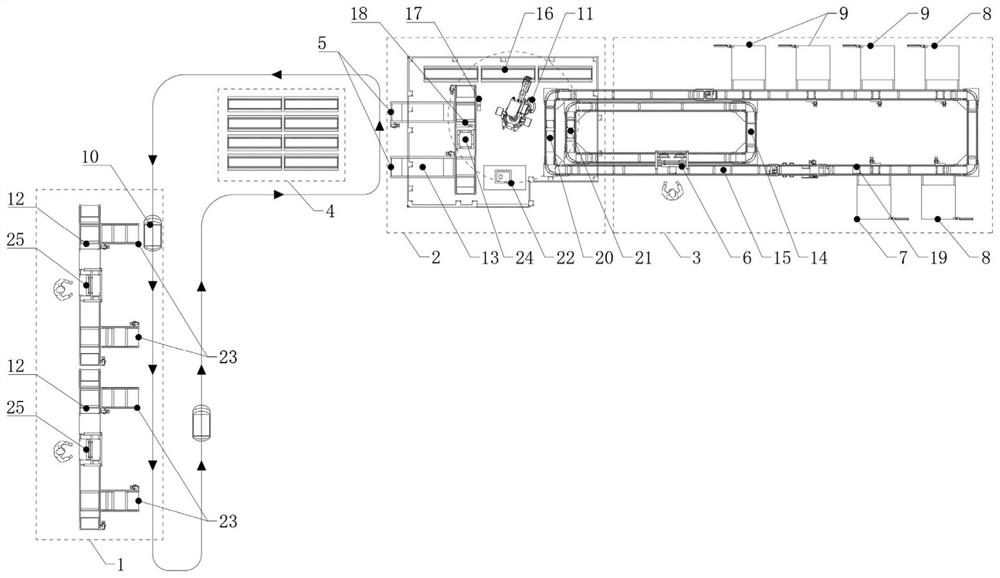

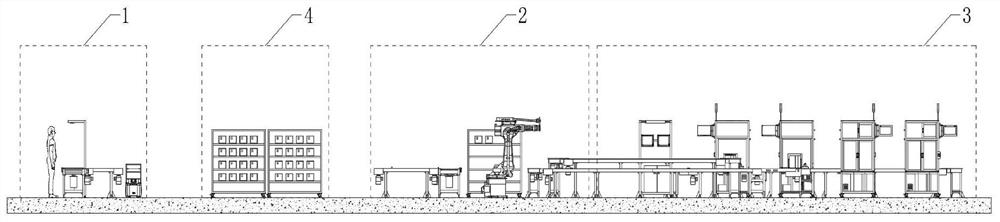

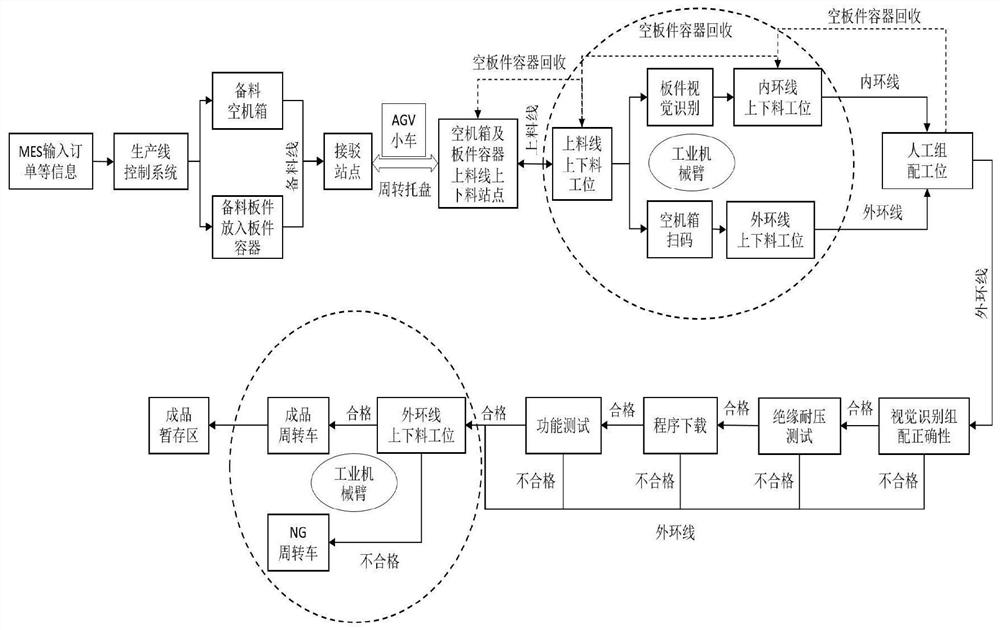

[0029] Such as figure 1 As shown, the intelligent production system of the power grid device of the present invention includes rationally planning the work area, configuring key hardware equipment such as transport vehicles, industrial manipulators, automatic transmission lines, device software downloading and testing equipment, and production line turnover containers. The system acts as a dispatch center to ensure the intelligent continuous production of the device.

[0030] The work area includes raw material preparation area 1, loading and unloading area 2, device assembly test production area 3, and finished product temporary storage area 4; the number of production line stations is reasonably arranged, including: 2 raw material preparation stations 25, and 1 device assembly Station 6, 1 insulation withstand voltage automatic test station...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com